Saint-Gobain Abrasives is part of the French corporate group Saint-Gobain S.A. (Paris), which is one of the world’s 100 most innovative companies. Saint-Gobain Abrasives being founded 135 years ago, has a long standing tradition, with more than 10,000 employees today, working tin 28 countries, building a presence on every continent.

Saint-Gobain Abrasives offers high-performance solutions for customers in almost every industrial sector as well as for professional end users who buy from specialist distributors. With its leading brands brands Norton®, Norton® Clipper®, Norton Winter®, Rasta®, Atlas® and Flexovit® Saint-Gobain Abrasives offers the most comprehensive range of abrasive solutions, also for ambitious DIY enthusiasts, too, can find an extensive range of abrasive equipment from leading in hardware and DIY stores.

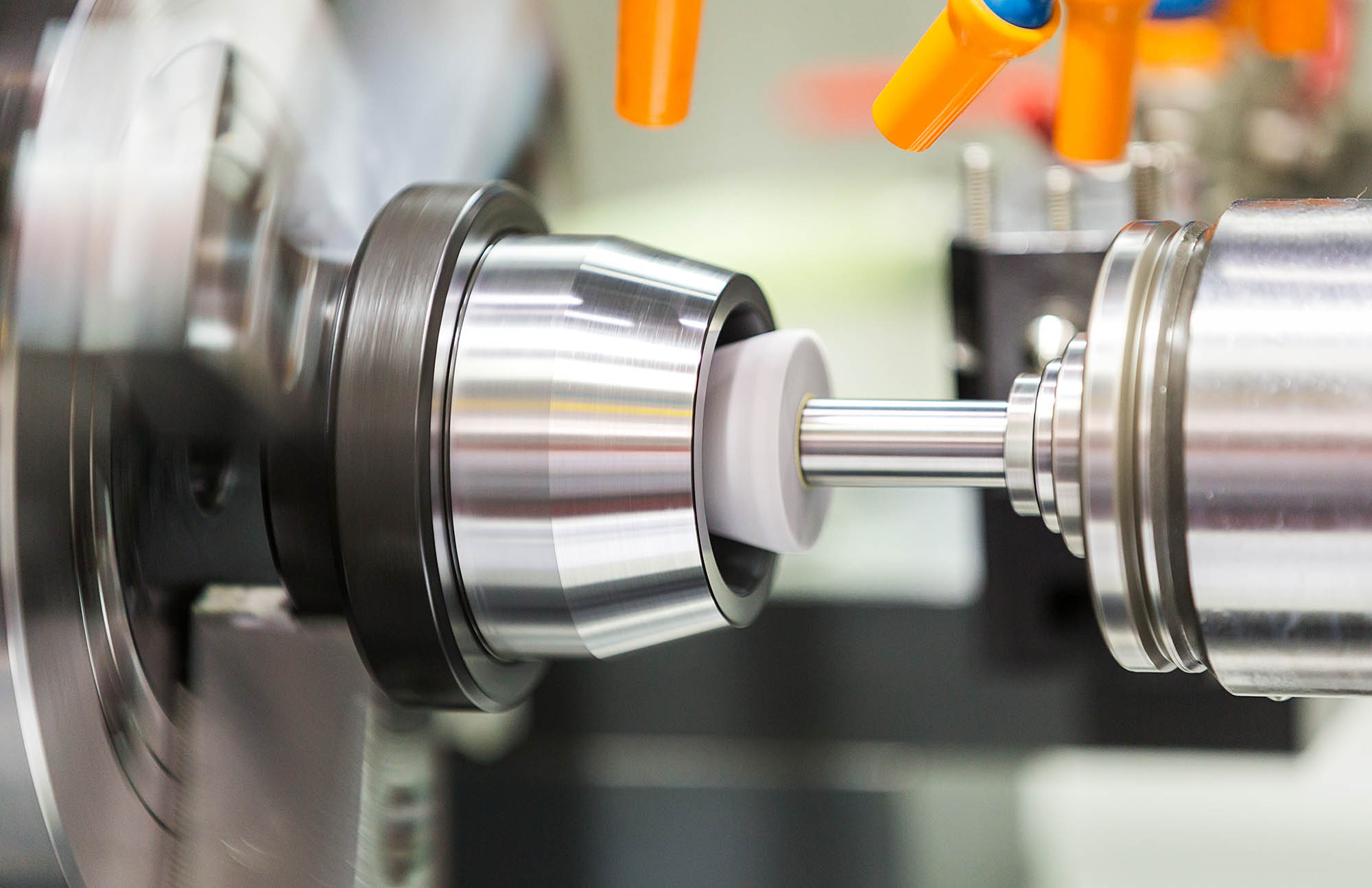

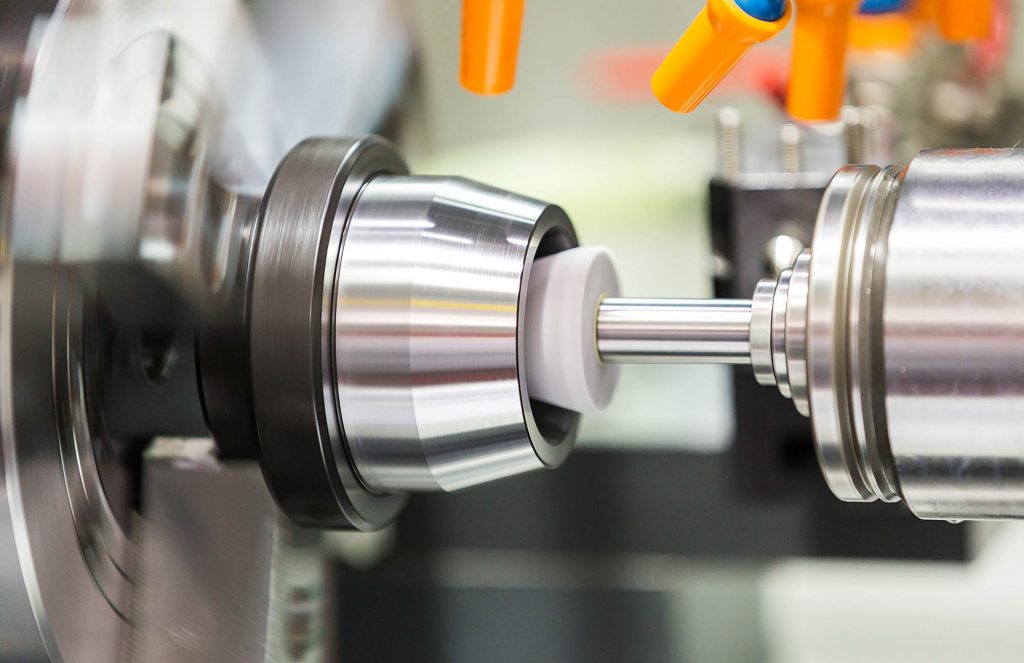

The company offers high-performance, user-friendly products to perform grinding work safely and comfortably on any material and achieve perfect results, even in highly challenging applications.

Easy Engineering: What are the company’s main areas of activity?

Saint-Gobain Abrasives: Saint-Gobain Abrasives brings together the world’s leading grinding technology brands in a unique and comprehensive product portfolio aimed at all areas of industry.

This portfolio includes a wide range of sustainable, high-performance complete solutions covering every processing step for precision applications in the industrial sector as well as for cut-off, grinding and finishing processes for professional applications in the MRO (maintenance, repair and operations), AAM (automotive) and DIY market segments.

Super abrasive industrial solutions and diamond tools as well as specially designed machinery for the construction sector from leading brand Norton Clipper complete the market portfolio.

Norton grinding solutions offer a cost-effective means of processing any type of material – whether steel, non-ferrous metals, compounds, concrete, asphalt, wood or glass – to the very highest quality, even in highly complex small-trade or industrial applications.

E.E: What can you tell us about the latest products released in 2020?

Saint-Gobain Abrasives: Outstanding examples of the latest innovations in the industrial sector:

- Norton IDeal Prime, the latest generation of internal grinding wheels for machining component bores on engine components, takes this special grinding application to a whole new level of performance. Narrowed tolerances, increased profile precision, improved surface finishes with simultaneously increased rates of material removal and longer dressing intervals are just some of the impressive ways in which this enhanced performance will help to significantly lower process costs.

- Light Comfort Grinding (LCG) is the new Norton solution for professional grinding applications, which is used especially for grinding/roughing work on metal and many other materials with cordless angle grinders. When the just 3-mm-thick LCG grinding wheels are used, the rechargeable batteries in the devices will last longer than ever before and remove much more material in this time.

- With the new Norton Clipper range for compaction work (e.g. in road construction and gardening/landscaping) and a comprehensive range of range of saw blades for timber construction, Norton Clipper is setting new standards in the construction industry.

- High-performance Norton Clipper systems with especially compatible Norton Clipper tools provide building professionals with outstanding results quickly and cost-effectively – not to mention reliably, sustainably and with less risk to health.

E.E: What product ranges do you offer?

Saint-Gobain Abrasives: Saint-Gobain Abrasives is the only international supplier that manufactures all the four main categories of abrasives – bonded abrasives (organic and vitrified), coated abrasives and cut-off- and grinding wheels and super abrasives – at its own facilities.

With a special focus on industrial processes – where maximum technological and economic performance is a must – we work in close collaboration with users to develop customized solutions specially optimised in line with specific machining requirements. Our individual developments help to boost our customers’ productivity, product quality and sustainability; for example, by reducing energy consumption and material requirements.

E.E: What is the market like in which you are currently active?

Saint-Gobain Abrasives: Saint-Gobain Abrasives operates in a market in which industry, small trades and ambitious DIY enthusiasts expect abrasive manufacturers to offer smart solutions that can help to cut costs and generate quality, are sustainable, offer the highest level of performance and lots more. Saint-Gobain Abrasives both fulfils and exceeds these challenging requirements thanks to its extensive and innovative product range.

E.E: What can you tell us about market trends?

Saint-Gobain Abrasives: In addition to the high quality and cost-effectiveness of the products that we offer, the other key market trends are sustainability and operator safety.

Our aim is to develop and offer solutions that not only set standards in terms of quality and performance, but are also easy and safe to use and have a reduced environmental impact.

Saint-Gobain Abrasives is, for example, a founder member of the Sustainable European Abrasive Manufacturers (SEAM) programme, which is promoted by the Federation of European Producers of Abrasives (FEPA). Its aim is to help abrasive manufacturers to achieve greater sustainability and responsible growth, primarily in the fields of trade and production.

Another trend is cordless equipment. Business is booming here – after all, power tools with rechargeable batteries are no longer the niche products they used to be many years ago. Under our Norton brand, we offer optimised grinding wheels featuring LCG technology specially designed for use on cordless angle grinders. These allow professionals from industry and the small trades to significantly increase the performance of their cordless machinery and so make huge time savings.

Another example is the electric Norton Clipper CE414 cut-off saw with 4.4 horsepower, which is more than a conventional petrol-powered cut-off saw and avoids pollutant emissions. With the low-noise Norton 350 mm Silencio diamond blade including Norton iHD™ segments, the CE414 is a highly sustainable cut-off saw that is kind to both the human operator and the environment and is ideally suited to use in enclosed spaces.

E.E: What are the most innovative products that you market?

Saint-Gobain Abrasives: For the ninth consecutive year, the Saint-Gobain Group recently appeared on the ‘Derwent Top 100 Global Innovators’ list, making it one of the 100 most innovative companies and institutions. A quarter of the products that Saint-Gobain sells today didn’t even exist five years ago. This outstanding achievement can be partly attributed to our subsidiary Saint-Gobain Abrasives, with its unceasing focus on innovation and R&D.

One example of our innovative output can be seen in our development of new processes in the manufacture of high-performance grain material as well as revolutionary bond technologies being essential prerequisites for new grinding solutions offering unprecedented leaps in performance. In these areas, our innovations are setting the standard on the market – including with premium brands Norton and Norton Winter with Quantum X , Vortex 2, IDeal Prime, Vitrium3 and Vitron7, which we configure and develop with different high-performance grinding tools for a range of industrial grinding processes.

Another example is the latest-generation Norton iHD™ bond system. This patented bond technology ensures a long-lasting and robust bond between the steel core and segments of our diamond blades. It is used in our ‘Mr Invincible’ diamond blades, making these among the safest diamond cut-off discs currently available on the market. Combined with sustainable manufacturing processes and outstanding cutting performance on all types of construction materials, iHD™ tools offer maximum safety and help you to save time and money on the building site.

The Norton Clipper Silencio diamond blades have also received numerous innovation awards. During the cutting of stone, paving slabs and other solid construction materials, these can reduce typical noise emissions by up to 25 dB and, in turn, the exposure level for operators by up to 30 times.

E.E: What are your forecasts for 2020?

Saint-Gobain Abrasives: The coronavirus pandemic makes results hard to anticipate. We are currently observing a tangible recovery, especially in the construction works. Overall, the trend for the remainder of 2020 is difficult to forecast.

Photos: Saint-Gobain Abrasives

SAINT-GOBAIN ABRASIVES GMBH

Birkenstraße 45-49, 50389 Wesseling, Deutschland

Gisela Nehls – Marketing Engineered Markets Germany

Tel.: + 49 (0) 22 36 – 703 – 633

Fax: + 49 (0) 22 36 – 703 – 610

E-Mail: gisela.nehls@saint-gobain.com

Site: http://www.saint-gobain-abrasives.com