SAMYLABS is a Basque company founded at the end of 2016 with the aim of developing 3D metal printers using laser technology. As a curiosity, SAMYLABS is the first and only Spanish company to fully develop all the necessary technology for 3D printing in metal using laser fusion, from the lamination software to the control electronics of the laser system. The company have been supported locally by various programs of the SPRI-Basque Agency for Business Development and the Provincial Council of Bizkaia, as well as nationally by CDTI programs.

SAMYLABS has ONA ELECTROEROSION as an industrial partner, one of the most important machine tool companies in the Basque Country, a pioneer in EDM technology, which provides SAMYLABS with high capacity and productive quality in its equipment, as well as a powerful sales network and technical service.

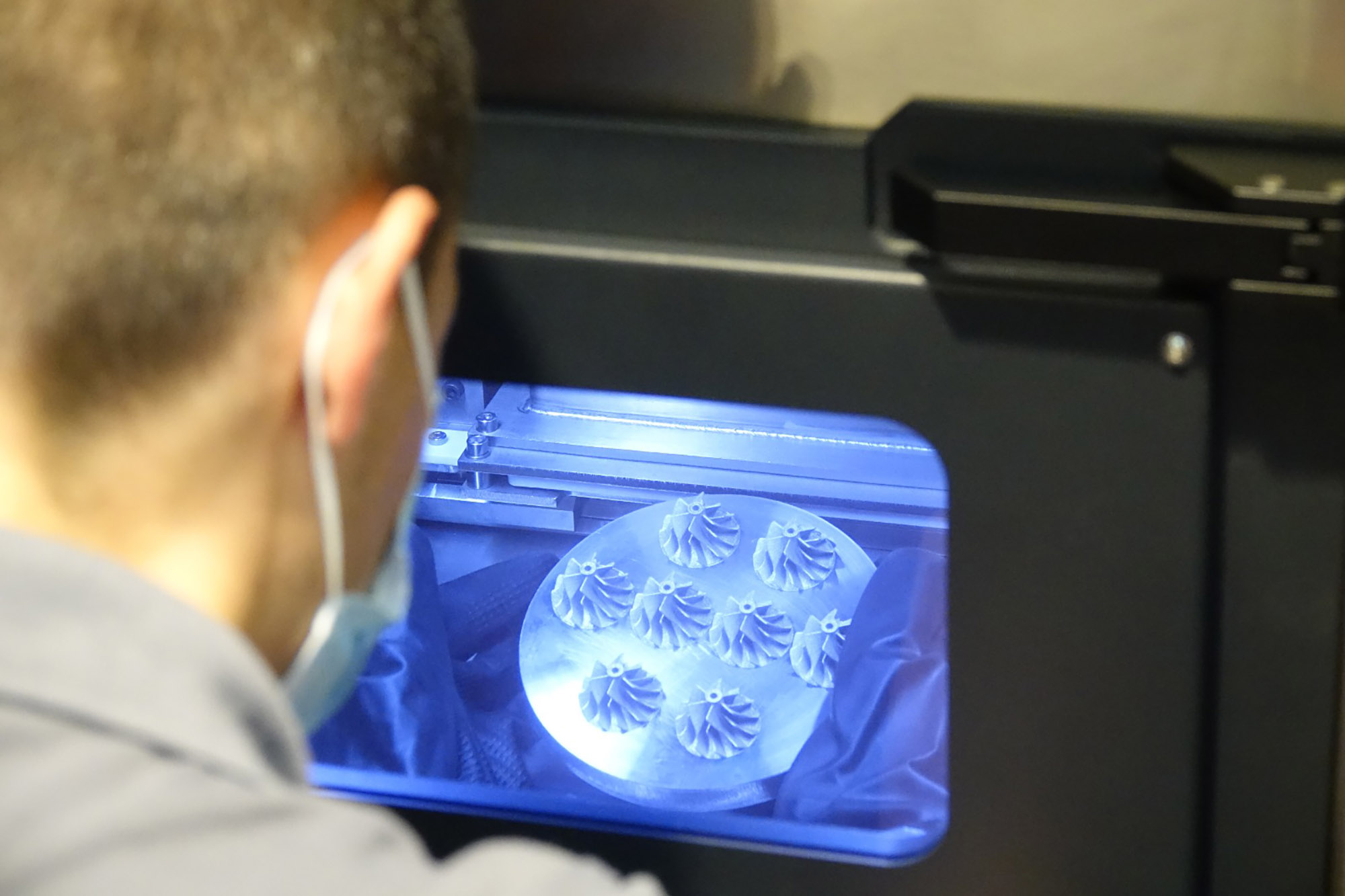

The company sells its model SAMYLABS ALBA300, a machine with a compact and economical design, which reduces the costs of laser fusion technology and brings professional 3D metal printing closer to small companies and educational centers.

E.E: What are the main areas of activity of the company?

SAMYLABS: The company is completely focused on the design, manufacture and sale of 3D metal printers with laser technology, for the educational sector, technological and research centers and auxiliary industry. The technology is also of interest to the medical-dental, automotive and aeronautical prosthetic sectors. Over time the company hopes to be able to enter these sectors.

E.E: What’s the news about new products?

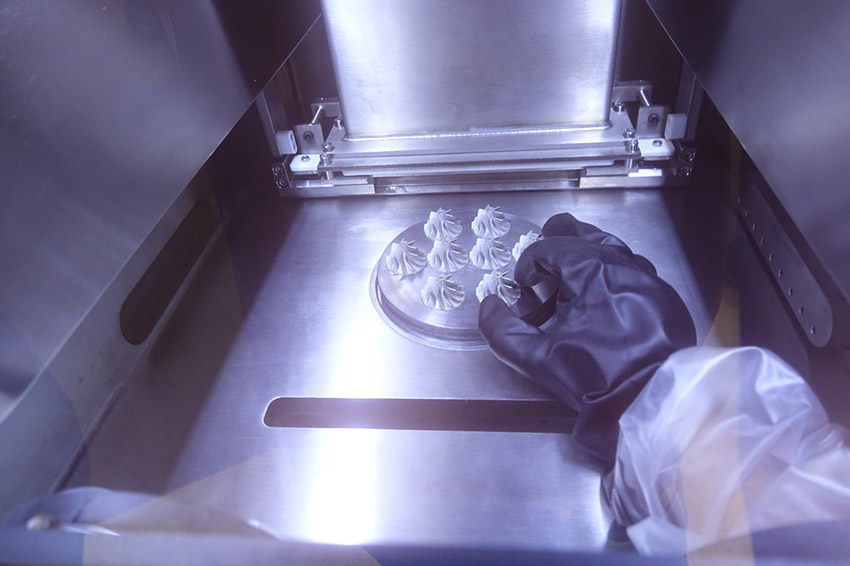

SAMYLABS: The latest model allows a larger cylindrical print volume of 200 mm in diameter and 250mm high, as well as printing on explosive risk materials such as Aluminum and Titanium. On the other hand, the company is making its software compatible with other technologies such as WAAM.

E.E: What are the ranges of products?

SAMYLABS: The company has a single business model, available in 2 print volumes. ALBA300 D160 H200 and ALBA300 D200 H250. At the same time, as parents of technology, we support collaboration and personalized development with centers and companies, both at the software level, as well as technology and machine adaptations.

E.E: At what stage is the market where you are currently active?

SAMYLABS: We mostly do commercial action at a national level (SPAIN) both through the firm itself, as well as our industrial partner ONA ELECTROEROSION and our distributor GRUPO SOLITIUM.

Through ONA’s commercial network we are also carrying out international sales activities. Specifically, this has already materialized with sales in Portugal, France, Italy and India. We currently have operations from many other countries of the European community.

E.E: What can you tell us about market trends?

SAMYLABS: The market is in a more mature state in which companies (especially in certain countries) are already finding the meaning and the correct application for the technology, beyond the noise and false expectations. Every day more niches and applications are discovered, where additive manufacturing has a higher return than traditional manufacturing, and many companies are betting on it. Our position is to try to facilitate access for the implementation of this technology, as well as the research process.

E.E: What are the most innovative products marketed?

SAMYLABS: More and more alloys with spectacular properties such as nitinol are discovered and the performance of the most common materials is improved, such as titanium or copper.

Being able to print on these materials is revolutionary for the world of electrode manufacturers, or the dental medical prosthetic sector.

There is also much progress in parallel in the world of post-processing, with hyperbaric treatments, for example, that improve the final performance of the parts.

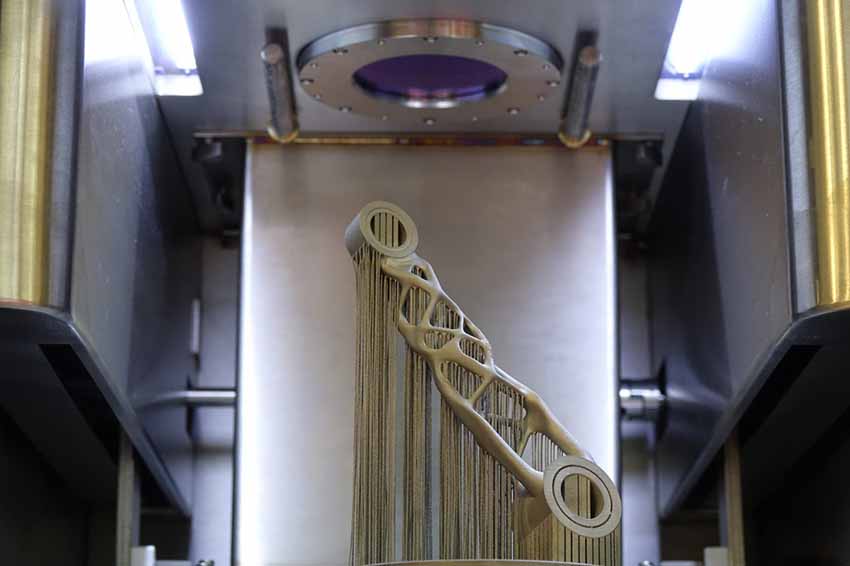

There are sectors, such as the world of mold inserts, where the benefits of additive manufacturing for the manufacture of parts with complex internal cooling ducts have been appreciated for a long time.

An industrial sector that is beginning to discover the potential and benefits of this technology is related to electrical penetration and 3D engraving.

With additive manufacturing, it is more competitive to generate parts with textures and surface reliefs.

E.E: What estimations do you have for 2023?

SAMYLABS: We hope to consolidate the company, with growth in sales nationwide and a greater international presence.

Until now, the brand was largely unknown, but more and more, it is beginning to sound like an option that many companies are considering.