Scanningspray Vertriebs GmbH (Dortmund, Germany) founded in 2018, has specialized in the development and manufacturing of 3D scan sprays. The team comprises of diverse specialists, but all with a sound background in 3D scanning and aerosol development.

With a wide network of distributors and reseller the products are available all over the world.

Easy Engineering: What are the main areas of activity of the company?

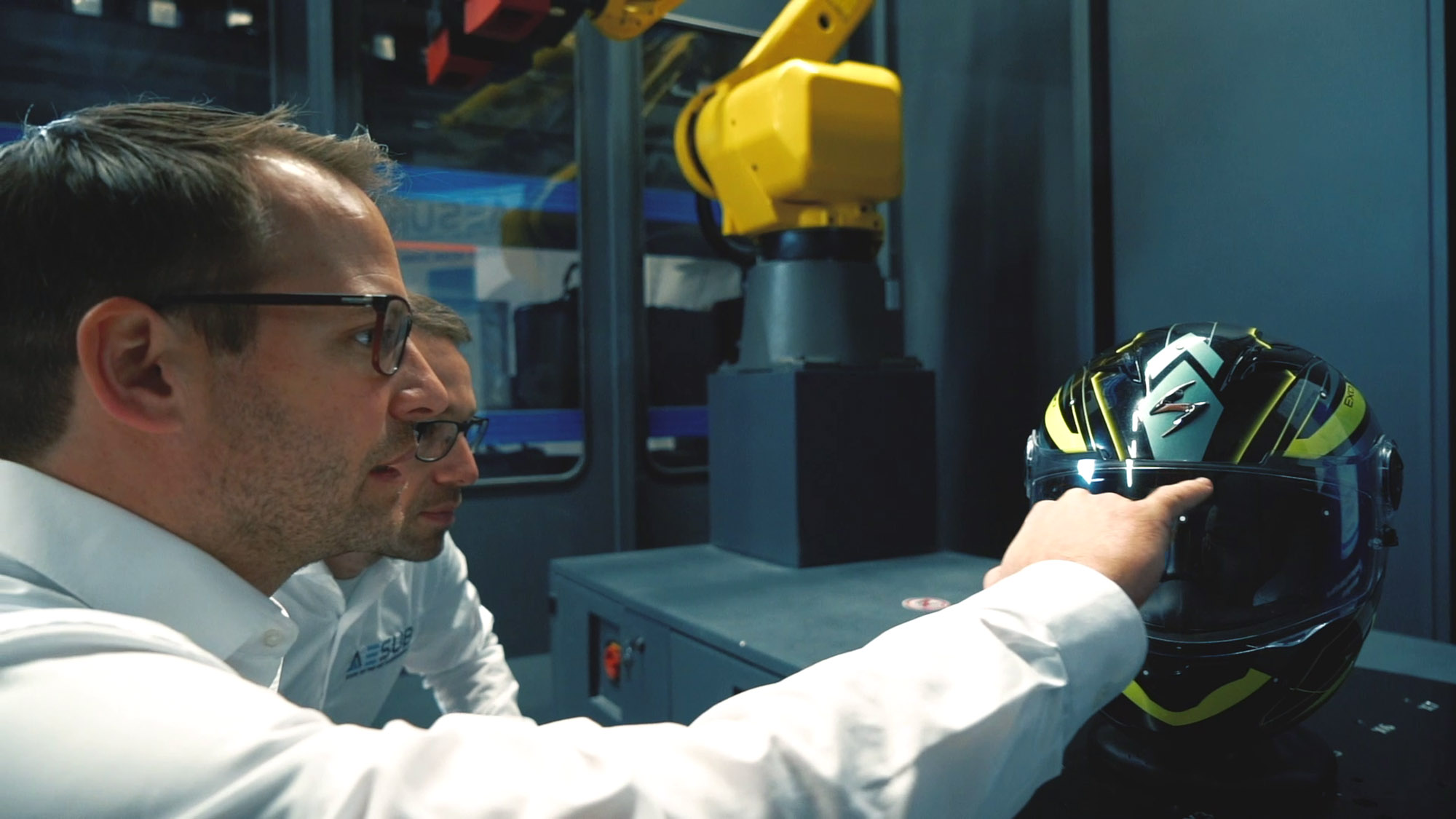

Scanningspray Vertriebs: AESUB products facilitate and enable optical digitalization in a wide variety of industrial sectors and range of applications. Manufacturing industries such as automotive, engineering

and aerospace, for example, use 3D scanning and thus benefit from AESUB products for quality control and inspection. Designers often use digitalization techniques and consumables such as AESUB for reverse engineering. Other industries and applications include the energy sector, tooling industry, architecture for e.g. digital archiving, optical metrology, research and development, process monitoring and inline scanning.

E.E: What’s the news about new products?

Scanningspray Vertriebs: Many optical scanners have difficulties when scanning shiny, transparent or reflective surfaces. In such cases, the surface of the scanned object has to be pre-treated before 3D scanning to achieve precise measurement results. For this reason. the objects are sprayed with a matting agent – so called Scanningsprays – to allow the scanner to capture the surface of the object.

Main advantages of AESUB Scanningsprays:

Sublimation

Unlike tradition sprays, AESUB sprays evaporate after scanning. After a few hours, the matt layer is completely gone. This protects the high-quality measurement device and saves time previously spent on cleaning the object. The evaporation time depends on the AESUB spray variant and can be between an hour and up to 24 hours.

Directly applicable on spot of scanning

With the self-evaporating Scanningsprays from AESUB, components can be directly sprayed next to the scanner, meaning no time is lost due to extra transport.

Higher effiency in measurement processes

The measuring process can start earlier. As no cleaning is required, the measuring capacity increases significantly with AESUB Scanningsprays.

No contamination of sensitive equipment

Using traditional pigment-based sprays, spraying has to take place outside the measurement area, as the mist of spray deposits on the surrounding area and could contaminate or damage the sensitive measurement devices. This means that the object to be scanned needs to be transported back and forth between measurement area and spraying site.

Time saving as no cleaning required

Even more laborious is the subsequent removal of the spray coating from the components. Depending on the component size, shape and material quality, cleaning can take several hours. Often, full removal – for parts with deep structures or sensitive surfaces – is impossible, meaning that the parts can no longer be used.

E.E: What are the ranges of products?

Scanningspray Vertriebs:

Scanning sprays

Currently, there are three sublimating spray variants of AESUB on the market. They differ in terms of sublimation time and thickness of the spray layer:

AESUB Blue

- Sublimations time: Up to 4 hours

- Effective scan time: 1- 2 hours

- Layer thickness: 8 -15 μm

- Coverage area: ~4m² per can

ASEUB Orange (Long-lasting)

- Sublimations time: 12 to 24 hours

- Effective scan time: 4 to 8 hours

- Layer thickness: 2 – 6 μm

- Coverage area: ~4 m² per can

AESUB Green (Spray Gun solution)

- Sublimation timeLasts: Up to 6 hours

- Effective scan time: 1 to 2 hours

- Layer thickness: 10 – 20 μm

- Coverage area: ~15m² per litre

Modular target frame

AESUB also offers a modular reference frame to hold smaller objects for optical measurements. The set allows to assemble frames with a diameter of 200mm or 300mm. All AM-printed elements are black and compactly packed into one case, making the entire set perfect for mobile use.

Flexible arms hold the object within the black frame so that it can be scanned from all angles. Reference points required for scanning can be placed directly on the frame instead of on the object. The frame also simplifies the measuring process of single parts that require front and back scans. Without a target frame, such parts would have to be covered with many reference points so that overlapping points are visible from both sides.

AESUB dots:

Reference points for universal 3D scanning

Until now, self-adhesive reference points were almost exclusively available as measuring accessories from the device manufacturers.

Now AESUB offers the points very quickly on short delivery routes and at the same time cost-effectively.

They can be placed on the measurement object before or after spraying with scanning spray. The reference points adhere to the spray coating and can be easily removed again.

The addition of scanner spray and dots makes digitizing shiny and reflective parts much faster and more convenient.

E.E: At what stage is the market where you are currently active?

Scanningspray Vertriebs: The 3D scanning and digitalization market has seen continuous growth due to a growing need and range of applications. Thanks to the innovative feature of sublimation of AESUB Scanningsprays, the range of application has further increased as it is now possible to also scan challenging surfaces in sensitive environments using a vanishing matting agent of AESUB. We expect this trend to also continue in the future since we see many companies investing in optical measurement equipment to have reliable measurement results quickly available. This is where our products come in, as they support, simplify and above all accelerate the measurement process. Where optical scanners reach their limits due to shiny or reflective surfaces, AESUB scanning sprays come into play.

E.E: What can you tell us about market trends?

Scanningspray Vertriebs: Achieve the highest quality at a fast and effective pace. Scrap needs to be avoided and costs reduced.

Therefore, the AESUB sprays are a useful addition to optical scanners. In combination with the AESUB dots, the entire measurement process can pick up speed significantly and deliver more accurate and reliable measurement results. For small components, the reference frame is a crucial addition for an all-round scan.

E.E: What are the most innovative products marketed?

Scanningspray Vertriebs: These are undoubtedly our scanning sprays. Their use often enables 3D in the first place, increases accuracy of the 3D measurements, saves time, avoids scraps. In addition, the vanishing AESUB products are free of pigments which might are be harmful to your health.

E.E: What estimations do you have for 2022?

Scanningspray Vertriebs: Whereas pigment-containing scanning sprays were once considered a necessary evil whose use was to be limited to the bare minimum, we are now seeing great use of our volatile scanning sprays. We believe that this first-mover trend will now become mainstream. Last but not least, our slogan is therefore AESUB State-of-the-Art Scanningspray: SPRAY | SCAN | DONE!