Schöck is a manufacturer and supplier of innovative building materials and services that support efficient construction. The family-owned company was founded in 1962 in Germany and has since grown to an international company with over 1000 employees and subsidiaries in 12 countries throughout Europe and North America. Through partners and representatives, Schöck products reach customers in all European markets, North America and in the far East, specifically China, Japan, and South Korea.

Easy Engineering: What are the main areas of activity of the company?

SCHÖCK: The main product solutions Schöck provides are structural thermal breaks, which are structural connecting elements that also serve as a layer of thermal insulation. With the brand Isokorb® building elements as balconies and parapets can be connected to the main structure in a way that is thermal bridge free. This helps create a continuous insulation layer at the building envelope, allowing maximum architectural flexibility while supporting an efficient design.

On top of thermal breaks Schöck also provides impact sound insulation products under the Tronsole® brand. These connectors are specifically designed to structurally support and acoustically insulate staircases. Additionally, Schöck provides other structural components such as shear dowels, punching shear reinforcement and a glass fibre reinforcement technology called Combar® which is also used in thermal bridge free façade anchors, Isolink®. The final activity area to mention is digitalisation, which is incorporated into everything done at the company, from providing architects and engineers with innovative software to plan their works to effectively managing the myriad internal data related to supply chain management, order to production management and customer relationship management. There is truly a lot going on!

E.E: What’s the news for 2021 about new products?

SCHÖCK: New in 2021 Schöck is excited to unveil the Sconnex® product line, which completes its structural thermal break system by offering solutions for walls and columns. Vertical structural requirements are challenging due to the high compression loading and the building’s dependency on those elements. It has been a multi-year effort to develop a structural thermal break for this area. It was not only an R&D effort, but also included a major acquisition of a Swiss company. With Sconnex® and Isokorb® all major structural thermal breaks of a building can be efficiently treated.

E.E: What are the ranges of products?

SCHÖCK: The ranges of products include:

- Isokorb® for minimizing thermal bridging at the connection of balconies, canopies and parapets in both steel and concrete construction;

- Sconnex® for minimizing thermal bridging at the connection of columns and walls in both concrete and masonry;

- Tronsole® for impact sound insulation of concrete staircases;

- Isolink® as a thermal bridge free façade anchor for both rainscreen cladding façades and concrete insulated sandwich walls;

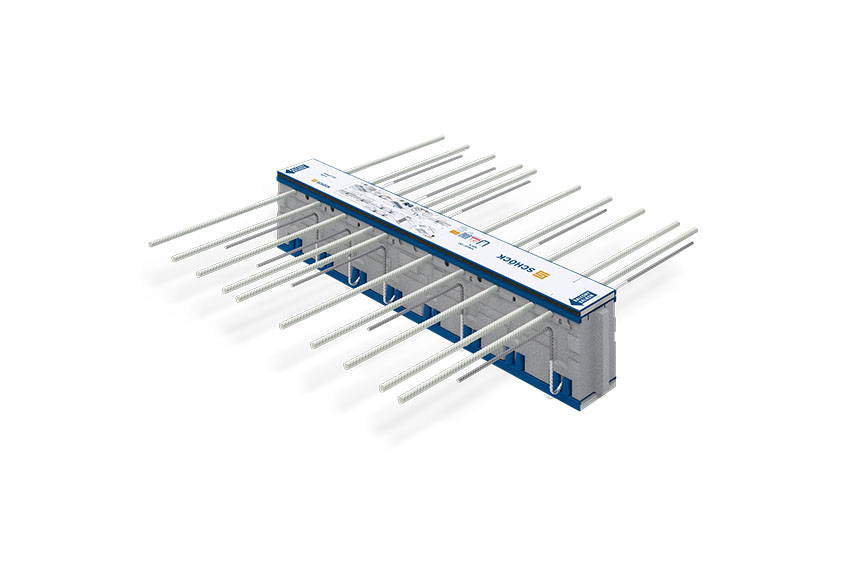

- Combar® GFR – glass fibre reinforcement;

- Dorn shear dowels for fixed and lateral movement structural joints;

- Bole® punching shear reinforcment to eliminate the need to column capitals in concrete slabs; and

- Signo® a permanent pre-finished formwork for precast balcony systems.

E.E: At what stage is the market where you are currently active?

SCHÖCK: It is difficult to give a simple answer to the question of market stage. This is because Schöck is active in different types of markets around the world: both mature and new markets. For example, Isokorb® was first sold as a balcony thermal break in Germany in 1983. Since then, German building codes have developed around this technology making Schöck an established leader in this mature market. Other western European markets have had their building codes account for thermal bridges only in the past 10-15 years. In new markets Schöck does not typically enjoy a strong support from the building code situation. Rather as a new entrant, Schöck focuses on education and consultive sales to architects and developers who are interested in efficient buildings. Schöck also leverages the world-wide popularity of Passivhaus design concepts, since Schöck offerings are a critical part of this style of design.

E.E: What can you tell us about market trends?

SCHÖCK: There is a real trend in the market towards more efficient building design. This is not a new trend in our home market of Germany since there have historically been stringent building standards in place due to the relatively high energy costs. But with the rising awareness of the need to reduce carbon emissions worldwide we see increasing interest in efficient building design. This is true even in regions which traditionally enjoy cheap energy costs. Digitalization is another key market trend, which Schöck is pursuing as described above.

E.E: What are the most innovative products marketed?

SCHÖCK: The Isokorb® structural thermal break has evolved with steady improvements through the years. Version 1 of the product first launched on the market in 1983. It was a rough and primitive version of what is now offered. Through the years components of the product have been optimized to improve thermal and structural performance. The latest step in this innovation has been in the implementation of the CXT version of the product. This version uses Combar® glass fibre reinforcement bars as the tension bars crossing the product. Since Combar® transmits virtually no heat energy, the overall thermal conductivity of this thermal break is extremely low. This allows the Isokorb® CXT to enjoy a Passivhaus certification. Besides, due to the use of glass fiber instead of steel, the product has a up to 27% better life cycle assessment in the manufacture. It is the most advanced structural thermal break available.

E.E: What estimations do you have for 2021?

SCHÖCK: The pandemic in the past year has affected markets in which we are active in different ways. Despite lockdowns and travel restrictions, in most cases construction activities have continued unabated. A big challenge currently is in supply chain issues which price increases for our raw materials across the board. Nevertheless, the trend of efficient building is the most important tailwind of support for our business, and Schöck is well poised to continue to supply the innovative products needed for these markets.