(STW) Schwarzwälder Textil-Werke Heinrich Kautzmann GmbH develops and produces high-quality fibres for different industries and applications. As leading specialists in fibre fillers, short cut fibres, fibrids & pulp, as well as customized solutions, STW processes all fibre materials; from natural fibres to synthetic fibres through to high-tech fibres.

Thanks to over a century of experience, continuous research and strong customer-orientation, they are able to react flexibly to new requirements with our bespoke fibre solutions. And since they are active in over 70 countries, you will always find a competent fibre expert in your vicinity.

Easy Engineering: What are the main areas of activity of the company?

STW: Due to the wide variety of properties, our fibres can be found in many different industries:

Construction products

The fibres used in construction have a lot to do. They provide a high reinforcement and inhibit crack-formation. They encourage thixotropic effects and enable easy processing. For decades, the fibre products from STW have met the highest requirements and will continue to do so in the future. With our large range of properties, we are able to offer fibre solutions to virtually every area in the construction industry.

Plastics

Plastics were one of the first and are still one of the most important fields of application for STW fibre fillers based on cotton, polyamide, polyester and glass fibres, as well as chopped threads. Our fibre products are used in various plastic types, e.g. as fillers for thermosetting and thermoplastic resins. For the rapidly growing biocomposites segment we offer a wide range of natural fibre fillers.

Specialty paper

STW fibres are used in a whole range of specialty papers such as indicator papers in medicine, security papers for banknotes and identity cards as well as decorative papers, non-woven wallpapers and friction papers for couplings.

They improve dimensional stability, tear-, wet- and folding strength. For heat-sealable papers, we offer special polyolefin fibres and fibrids.

Automotive

Brake and clutch linings for passenger cars and commercial vehicles are safety-specific components. This is why raw material quality and well-designed, precision processing, play such an important role in STW’s fibre products for such vehicle components as friction linings. Not only do STW’s customers benefit from the high quality standards of its fibre production but so too, do end users. Many large friction lining manufacturers, worldwide, rely on our leading competence in the field of fibres. We develop fibre fillers, fibrids & pulp and short cut fibres that precisely meet customers’ targeted requirements.

Filtration

Both STW’s organic and inorganic fibres which are used in filter papers for the automotive, industrial and food sectors, offer an extremely high degree of purity and some of our fibre types are even approved for use in the supply of drinking water. The addition of fibres with predefined thickness or length also optimizes the dimensional stability and porosity of filter papers.

Rubber products

Fibres from STW can be found in many V-belts, toothed belts and seals, as well as industrial and household gloves. Fibres obviate the complex fabrics traditionally used in these belts, and thus facilitate more versatile products with greater flexibility and vastly improved transmission ratios.

Thanks to our fibre products, durable seals can be produced without asbestos. Our cotton fibres are used in many types of industrial and household gloves to promote comfort, moisture wicking and durability.

Customized fibre solutions

Thanks to decades of experience and as technology leader in the sector, we co-operate with you in developing the perfect fibre solution for your products, with outstanding quality and cost-effectiveness.

E.E: What’s the news for 2021 about new products?

STW: In addition to products for filtration and specialty papers, we are also increasingly focusing on natural fibers. Some customers have started to review their existing formulations to see if individual components can be replaced with more sustainable components. The objective is to reduce the CO2 footprint.

E.E: What are the ranges of products?

We distinguish between three main production areas which are fibres fillers, short cut fibres and fibrids & pulp.

Employing unique grinding technology, fibre fillers are made from randomly-oriented fibres, continuous fibres, threads or woven textiles, again, often according to your individual requirements, and often using fibres from the recycling sector. In this way, depending on fibre fineness and specification, we can produce products with a high degree of purity and uniform fibre length distribution.

Our short cut fibres have a defined length and are produced from continuous fibre tows made especially for STW. With in-house-developed production processes, we cut fibre tows into short cut fibres, to which adhesion promoters are applied matched to end applications. When cutting the fibres, we only influence the fibre length, which is one of the decisive quality criteria.

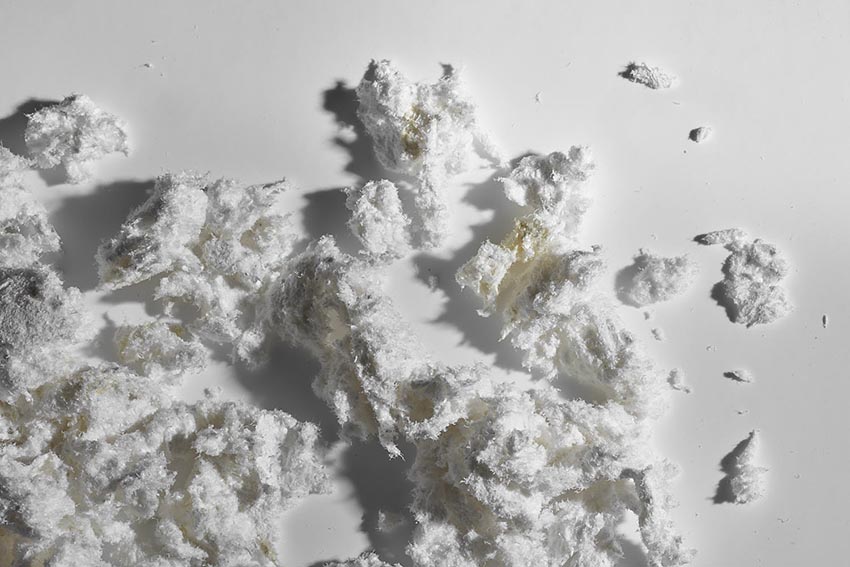

Fibrillated fibres have mechanical properties which are the same as, or similar to, those of the corresponding fibre types in filler or short cut fibre form. Their main differences derive from their branched structure (fibrils) and their demonstrably, substantially greater surface area. Owing to these specific properties of the fibres, additional effects are derived, e.g. thixotropic properties.

In accordance to the variety of applications, we also offer a wide product range consisting of natural fibres (cotton, sisal, coconut, flax, jute etc.) and synthetic fibres (aramid, basalt, carbon, glass, polyacrylonitrile, polyamide, polyester, polyethylene, polyvinylalcohol etc.). The different material and product group are available in several grinding grades, short cut lengths and often also as fibrids.

In addition to our comprehensive standard program, we offer individually tailored fibre solutions according to your requirements. In order to meet your needs, we also carry out special test projects and trials.

E.E: At what stage is the market where you are currently active?

STW: Within our customer structure there is a large number of very different industries as described above. Therefore, the question cannot be answered so simply. The thermoset plastics sector is certainly one that has been in decline for years. There is moderate growth in other areas.

E.E: What can you tell us about market trends?

STW: As already mentioned, many R&D departments are currently trying to develop more sustainable products to reduce the CO2 footprint. The current political decisions in favor of electromobility are forcing them to develop lighter components with the same or better performance. This is where we come in with our know-how and access to international raw material sources.

E.E: What are the most innovative products marketed?

STW: The most innovative products from our company are undoubtedly our fibrillated fibres (=pulp). Here we are able to optimally adjust the degree of fibrillation through our process know-how. The customer thus receives fibrids with a defined fibre surface. Furthermore, STW has – as already mentioned – a very wide range in the field of natural fibres.

E.E: What estimations do you have for 2021?

STW: The needs of our society are changing right now. We see this in the current discussion about climate change. Topics such as sustainability, CO2 reduction and weight reduction, especially in vehicle construction, will be the topics/challenges of the next few years.