ScrapeTec Trading GmbH was founded by Wilfried Dünnwald, a former mining engineer. He develops the innovative and patented products that the company now sells worldwide. In addition to Head of Sales Thorsten Koth, his team also includes employees who support him in development, technical implementation and distribution.

The company is based in Kamp-Lintfort in Germany, a former stronghold of hard coal mining. ScrapeTec cooperates worldwide with partners who use ScrapeTec products in solutions for their customers in mining, cement and gypsum production and food production. The company has been active in the market since 2014.

Interview with Thorsten Koth, Head of Distribution at ScrapeTec Trading GmbH.

Easy Engineering: What are the main areas of activity of the company?

Thorsten Koth: ScrapeTec focuses on the transfer points to conveyor systems. Thanks to their innovative way of working, the products ensure amazing results in avoiding dust development and material losses. The motivation of the owner and founder Wilfried Dünnwald for the development of the products was primarily the creation of better working conditions for the employees at conveyor systems.

E.E: What’s the news about new products?

T.K: The latest product is the E-PrimeTracker presented at BAUMA 2022. A deflection roller on the underside of the belt, which acts as a conveyor belt tracking assistant, which permanently counteracts belt misalignment and, thanks to its sensors, supplies relevant data on the belt travel status to the monitoring systems. In the spirit of predictive maintenance. Thanks to its sensors, the E-PrimeTracker is the digital upgrade to the successfully used analog PrimeTracker

E.E: What are the ranges of products?

T.K: The ScrapeTec solutions focus on the transfer to belt conveyors. The first development with which ScrapeTec entered the market was the AirScrape. A non-contact side seal for chutes. It floats above the belt and, thanks to the special lamellar structure, allows air to be sucked inwards. The TailScrape rear seal, which is adapted to the curvature of the belt, also works according to this principle. In the area in front of the chute, the DustScrape eliminates rising dust. As lane keeping assistants, PrimeTracker and E-PrimeTracker ensure a safe, constant distance between belt and seals. ScrapeTec offers the SureSupport solution to reduce belt loads caused by bulk belts in the feed area. Its special sliding surfaces avoid belt deformation and ensure optimal belt travel. All of these products are understood to be a dust protection solution for everything to do with the handover.

E.E: At what stage is the market where you are currently active?

T.K: ScrapeTec is active wherever the need to reduce dust generation at transfer points of belt conveyors has been identified. Due to the developing responsibility for employee health, environmental protection, cost minimization and sustainability in investment protection, the demand for ScrapeTec solutions has increased.

E.E: What can you tell us about market trends?

T.K: The recognizable trend is clearly towards predictive maintenance and sustainability. Continuous maintenance reduces costs and avoids damage. The avoidance of dust and spills also sustainably increases the service life of the systems. Ultimately, these are also important economic arguments.

E.E: What are the most innovative products marketed?

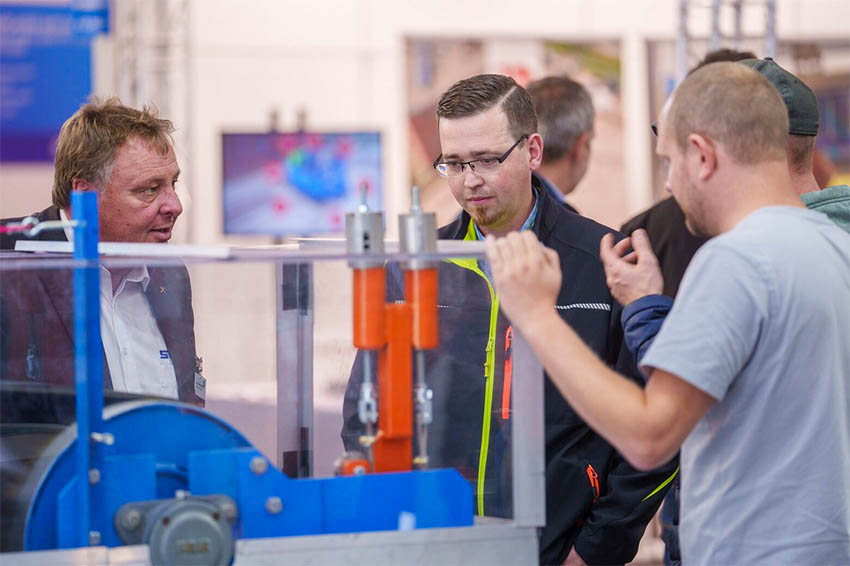

T.K: Actually, all products in the ScrapeTec portfolio are to be understood as innovations. This shows again and again in the presentations at relevant trade fairs around the world. The use of the products is often presented on a model, the focus conveyor belt. Here, the functioning of all ScrapeTec solutions is demonstrated during operation using a shortened belt installation. The visitor numbers at the booth are proof of the high demand

E.E: What estimations do you have for the rest of 2022?

T.K: In 2022 and also in the first months of 2023, ScrapeTec is busy processing the more than 200 contacts from BAUMA 2022. Added to this are the new orders from Israel, India and other countries, which are processed with great care in Kamp-Lintfort.