SED – Special Electronic Design srl – is a 45 year old Italian Company specialist in automation solutions and motor controlling for OEMs.

Easy Engineering: What are the main areas of activity of the company?

SED: At SED we design and manufacture customized electronics that drive industrial electric vehicles machines used for intralogistics, cleaning, packaging agriculture and medical devices.

In Today’s Industry, motor controllers are in-fact the backbone of many applications and present in every-day machines. They are well hidden, nevertheless they play a key role in industries helping to accomplish repetitive or heavy work, easing our way of living, making it more sustainable.

Of course, motor controllers need to be controlled by human, and this is the reason why, over the past years/decades (VEDI TE) SED has developed a wide range of instruments and human-machine interfaces.

E.E: What’s the news for 2020 about new products?

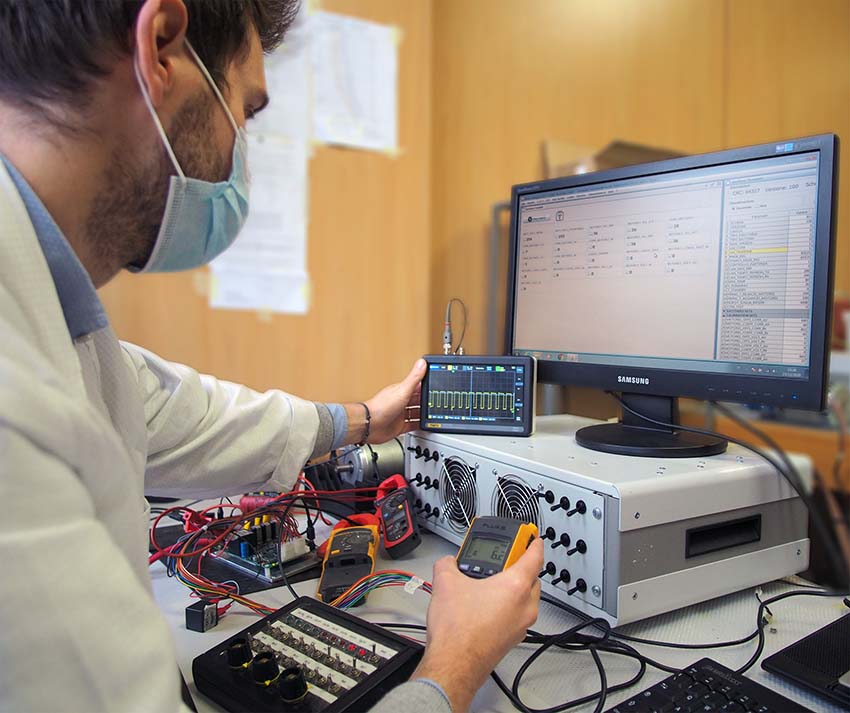

SED: 2020 has been crucial for SED, despite the COVID worldwide crisis, SED decided to invest in many areas: from the development of safety relevant controllers to advanced human interfaces for automated vehicles. The most important achievement is the development of a new platform that complies with the most advanced safety standard such as ISO 13849 and IEC 61508. The R&D team really worked hard to present to the market a set of new solutions that ensures to SED customer an easier certification path, a safer machine, and a true competitive advantage over their competitors.

E.E: What are the ranges of traded products?

SED: SED main product categories are the custom-made devices and the market-ready devices. According to the customer needs, we agree with the client whether to design something specific and proprietary or use one of SED standard solutions.

In term of technology, SED is specialist of low voltage applications – so everything which follows normally between 12 Volts and 96 Volts – however there are also some 220V devices. In term of power, the R&D office normally handles applications with motors up to 4kW.

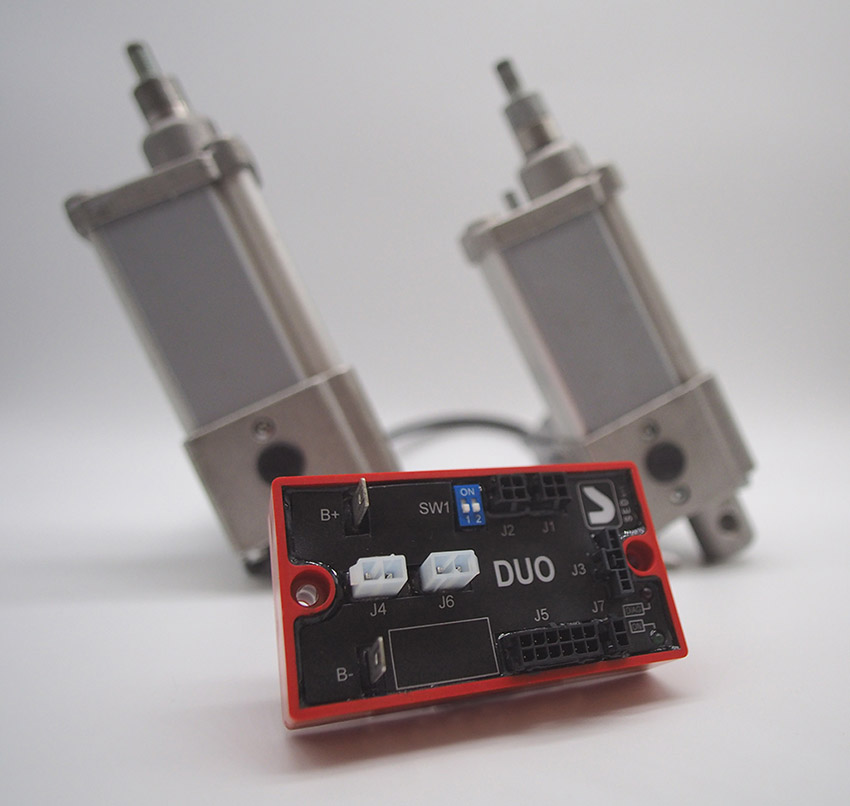

One of the most interesting SED products is a motor controller for 24V machine that can drive up to 5 motors independently delivering a total power up to 400 Amps. It is very versatile because it can be scaled up or down easily to optimize its cost, and it is fully programmable to fit virtually any application. Last but not least, it has an embedded CANbus connection, which means that it can talk to any other CANopen device, display or controller connected with this protocol.

E.E: At what stage is the market where you are currently active?

SED: Today we experience an electrification mega-trend. Indeed, you can see this all around in our daily life, and the electric cars are just the top of the iceberg.

The maturity of electrification trend is still far. This is surely good for the business but also brings high complexity in the electronic industry: all microchips producers are launching new products on the market almost every month thanks to the innovation impulse, and there is an on-going strong specialization on the components (i.e.: the controller raw materials). This makes the designer’s life much harder. Only well-established and experienced companies know how to select the right component, not only from the technology perspective, but also in term of supplies continuity. Selecting a wrong component could mean bad results and performance of your electric vehicle or machine, or sudden shortage of components and production stops.

E.E: What can you tell us about market trends?

SED: Looking into the individual end-market (e.g: Intralogistics, Cleaning) there is a stable growth thanks to the increase of people demands of products, which drives to more goods to be handled, or more mall to be cleaned for examples. COVID-19 marginally affected the demand increase. Let’s think about cleaning for example.

On the other hand, COVID-19 widely affected the supply chain of raw materials.

A lot of OEMs which sourcing in the far east (APAC) experienced huge delays and shortage of materials, both due to factories shut-down or transports delays.

SED, thanks to its internal production and a good network of suppliers, mostly based in Italy or EU, could guarantee the continuous supply of products also to those critical sectors like medical device and hospital bed producers.

E.E: What are the most innovative products marketed?

SED: I would pick our new ISO 13849 PL-d controllers, an extremely safe, reliable and powerful range of products; but also, our new HMI for autonomous vehicles. It is a little marvel of our R&D, in few inches we could fit a touchscreen display with customizable programs and graphic, a rail-way grade electronic with redundant CPU and plenty I/Os. That is not all! Early next year we will present a controller with an embedded IoT connection.

E.E: What estimations do you have for 2020?

SED: 2020 will close with stable growth compared to 2019. We are happy about that because most companies were affected by a shrink in figures. SED markets mix allowed SED to ensure a good performance which lead to a large new investment. We just installed a new SMT line and increased the PTH working area of about 3000sqm.

We look forward to 2021 as an outstanding year for SED enriched by our brand new production area to cuddle our clients with amazing new products.