Senzoro is an Austrian-based Start Up, active in the field of predictive maintenance. They are the first company in the world, which combined ultrasound-technology and artificial intelligence on industrial scale. Senzoro’s products and services are used in several industries and the zero-investment approach is unique in the market.

An interview with Markus Loinig, CEO at Senzoro.

Easy Engineering: What are the main areas of activity of the company?

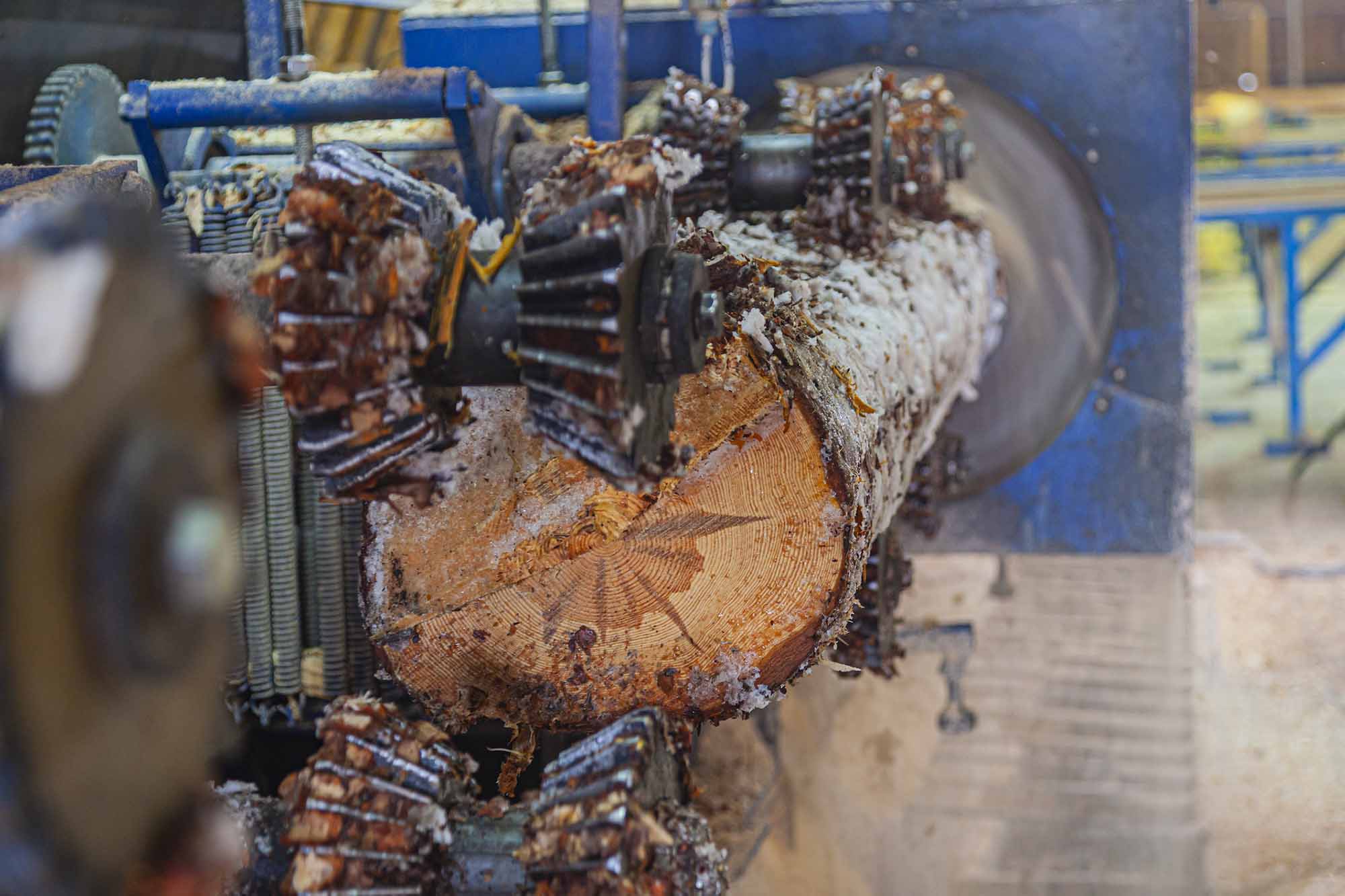

Markus Loinig: We have a strong focus on asset-driven industries where maintenance costs and resource efficiency play an important role. Currently we are active in the paper-, automotive-, timber-, chemical- and utilities industries. Our service is always used to transform the maintenance activities from time-based to predictive-based changing of spare parts. This saves costs and our planets resources. Looking into the future: We are also part of a research-consortium in the aerospace-industry, where we develop an artificial intelligence, which is able to predict corrosion in certain parts of the airplane.

E.E: What’s the news for 2020 about new products?

M.L: As part of our technology-roadmap, and certainly facilitated by the pandemic, we enabled our clients to conduct ultrasound-measurements by themselves and transfer data to us. This enables our clients to use our artificial intelligence (AI) in a „self-service” manner, whenever they need it and without any human intervention.

E.E: What are the ranges of traded products?

M.L: Our clients can either work with us on an „All inclusive” base, where Senzoro-experts conduct measurements on site and provide the corresponding predictions of our artificial intelligence. In this case, our clients don’t need to take care of anything. It’s also called our „suitcase-service”, because we really visit our clients with a suitcase. Our second option is the „Remote-AI”, where clients buy the measurement device and sent data to us via an upload portal. We currently focus on the GSA (Germany, Austria and Switzerland) market, but the „Remote-AI” option is also used in other European markets.

E.E: At what stage is the market where you are currently active?

M.L: The predictive maintenance market is growing fast, but broad adoption is still only done by the innovation leaders. Most companies are still waiting which technology will emerge as the dominant one, before they make their move. We do strongly believe, that ultrasound-technology and artificial intelligence are a perfect fit and will become the dominant technology. The reasons would go beyond this interview, but the reasons are well laid out in the blog-section of our webpage (https://www.senzoro.com/blog1).

E.E: What can you tell us about market trends?

M.L: The market is still very fragmented and it’s not possible for industrial companies to buy a predictive maintenance solution which really solves their problem “off the shelve”. The market is still divided into companies who „sell hardware and sensors” and others who „provide data science services”. In marketing messages, all of them claim to sell predictive maintenance solutions, but what they really sell is only parts of it. What companies need is a system which predicts remaining lifetime of their critical components. They don’t want to start collecting data, they want to buy a system which can predict remaining lifetime right off the shelve. And they are right to demand this, because it’s possible.

Let’s take electric motors as an example: Millions of motors are running around the world and the characteristics of how they fail are well understood. So, every predictive maintenance solution will need to have an AI on board, which can predict remaining lifetime for certain components from the first second on. Imagine this: You attach the sensor to the motor, the AI recognizes this being a „bearing of a motor” and calculates the remaining lifetime. This is what we do, and this is the future. All other products and services without this „build in AI powerhouse” will feel like surfing the internet with a 56k modem and die very soon.

E.E: What are the most innovative products marketed?

M.L: In the predictive maintenance field, I do believe, that we offer the most innovative and cost-effective solution in the market. Our clients do not need big investments in sensor technology, and they do get AI off the shelve which delivers results at the first second. At the same time, our AI streamlines any analysis process in an unprecedented way, as it can evaluate an infinite number of ultrasound measurements at the same time, with no human intervention. In the data science field, the pipeline for delivering AI to edge computing devices is taking shape. The recent activities by google (“TinyML”) will make it easier to deploy, use and maintain AI on the edge.

E.E: What estimations do you have for 2020?

M.L: Making factories more resilient to unplanned downtimes in times of the pandemic is certainly a major driver for our technology and this will continue for quite some time. Certain industries had to double or triple their production in short time, so maintenance needed to keep up at the same pace. Their old system of „changing parts every 2 years” was totally out of sync, as the demand on machines (produce more and produce it faster) changed the way parts degraded significantly, so unplanned downtimes skyrocketed. This was an unexpected booster for the products and services we offer.

But sooner or later, the effects of the pandemic will be over, and the focus will shift to the long-term problems again. Cost-pressure on companies will remain and the ones who can change spare parts exactly before they break will be more efficient than the one changing it every two years. Apart from that, companies still need to save resources such as CO2 to meet regulatory targets. As every spare part changed to early means a waste of resources, both in material and labour, predictive maintenance can also contribute to a „greener” production. Predictive maintenance technologies in general contribute to a more sustainable way of producing products and will therefore have a bright future.