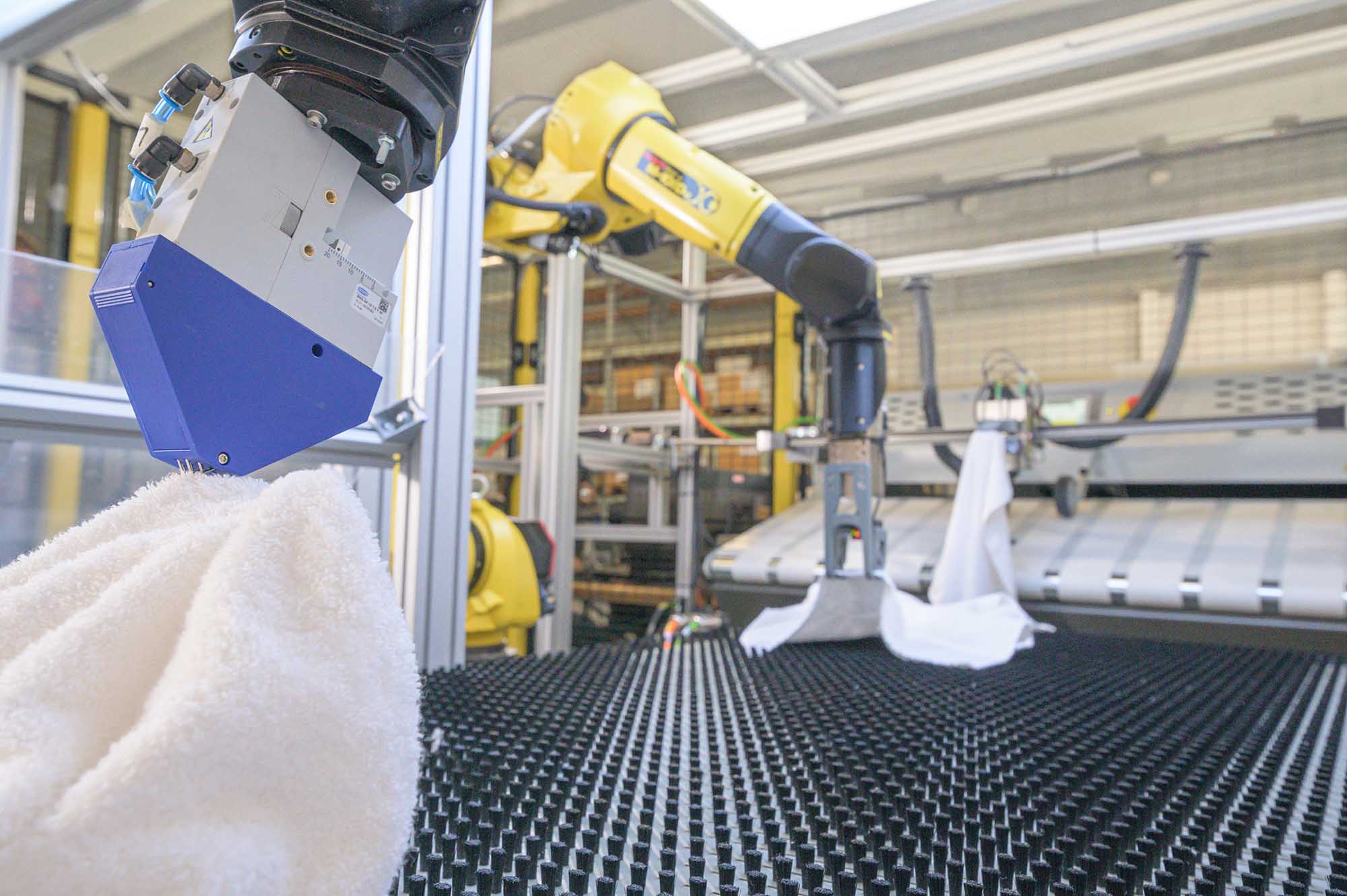

sewts is a robotics startup bridging one of the last gaps of industrial automation. By providing robots with human-like perception skills, they make the automatic handling of easily deformable materials (like textiles, foils or cables) possible. Because these materials are considerably more complex than solid materials – they constantly change their geometry while being handled and they require more dexterity, this has been an unsolved challenge so far.

Interview with Teresa Krebs, People, Culture & Marketing Manager at sewts.

Easy Engineering: What are the main areas of activity of the company?

Teresa Krebs: We’re developing software that combines commercial robots, grippers and cameras into an intelligent system to enable the automation of processes that were previously not technically feasible. So even though we are mainly focused on developing software (Computer Vision, AI, robot controls), what we’re selling is an entire system that automates an industrial process that is currently done manually.

Our first product is the VELUM system, a solution for industrial laundries. Industrial laundries wash and dry textiles in a highly automated environment to cope with the large quantities of dirty linen. There are even machines for folding laundry. But they have one major drawback: Each machine requires an employee to feed the laundry spread out and without wrinkles.

That’s where our VELUM system comes in. sewts VELUM feeds towels into existing folding machines, closing this gap in automation.

E.E: What’s the news about new products?

T.K: At the moment, we are focusing on bringing the VELUM product to the market and delivering the first systems to our customers.

We are however also starting our second use-case, which will be in e-commerce fashion returns handling.

E.E: What are the ranges of products?

T.K: Our first product is the VELUM system for automating the feeding of folding machines, the second product will be automating the handling of fashion returns in e-commerce. So, both of our first products will be centered on the handling of textiles, which is an industry that has a lot of potential for automation. However, our software is also meant to help automate processes that involve materials like foils, foams, cables, rubber, or even food.

E.E: At what stage is the market where you are currently active?

T.K: Right now, we are the only startup working on this issue in the scope that we’re targeting (which is developing software that can be used to automate many different use-cases involving the handling of easily deformable materials). Of course, if you’re looking at specific use-cases, there are other ideas on how to automate those, but not in an overarching way as with our technology.

E.E: What can you tell us about market trends?

T.K: The last few years have been especially difficult for quite a few industries – we have an ongoing supply chain crisis, inflation and a developing labor shortage. Automation and reshoring are trends that grow in importance because of those factors and we observe that they’re being discussed more and more, both in our conversations with potential customers as well as in the public.

E.E: What are the most innovative products marketed?

T.K: Our main innovations are without a doubt our Computer Vision and our AI, which enables our systems to analyze textiles and other deformable materials and translate the findings in to robot commands.

E.E: What estimations do you have for the rest of 2022?

T.K: Our main goal is to deliver the first VELUM systems to our customers and to continue developing our second use-case.