Sherpa Mobile Robotics (SMR) develops, produces and sells the SHERPA® range of autonomous and mobile robots (AMR). As inventor of the combination of follow-me and autonomous modes, SMR offers innovative and flexible solutions in order to reduce pain, automate your transfers, streamline flows and increase productivity. For more information, please visit their website at www.sherpa-mr.com.

Easy Engineering: What are the main areas of activity of the company?

SMR: Mobile robotics for industry logistics (kitting, line feeding), industry production (transfers of parts), logistics (material handling), retail (feeding goods), e-commerce (inbounds, picking, sorting, outbounds, returns), but also for medical, services, transport etc.

E.E: What’s the news for 2020 about new products? What are the ranges of traded products?

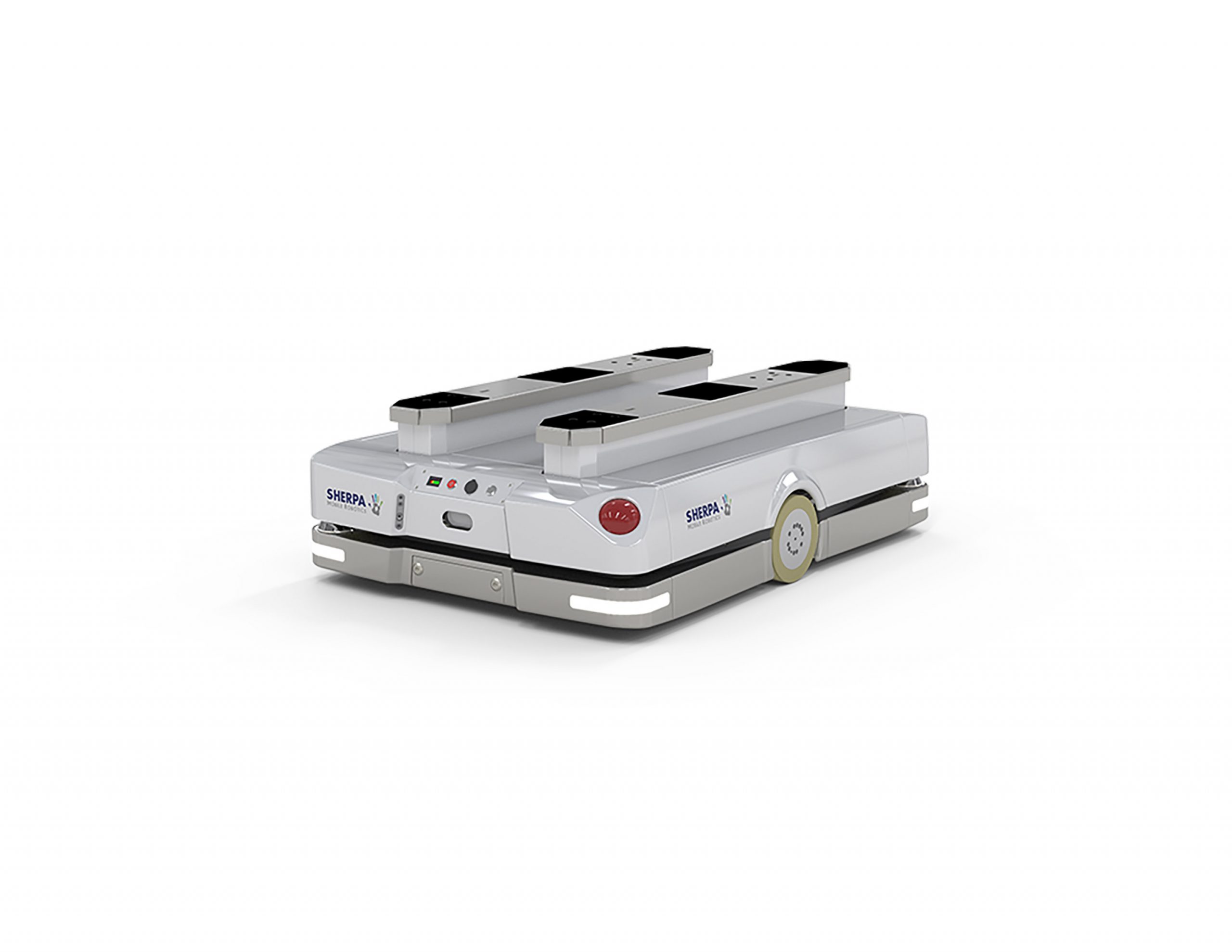

SMR: The SHERPA-B is the first born of our range. Its main objective is : moving / transporting bins.

The SHERPA-BD is the robot launched since a few weeks for the disinfection and to fight against COVID.

In September, we will launch the SHERPA-P for moving and transporting pallets. Until the end of the year, the SHERPA-W will be available on the market. Its a multitasking robot.

E.E: Concerning the SHERPA BD for the disinfection

SMR: As decontamination begins, SHERPA MOBILE ROBOTICS (SMR) and DEVEA are joining forces to propose a unique offer for autonomous disinfection by combining two innovative technologies: SHERPA® which is a mobile and collaborative robot and PHILEAS® which is an airborne surface disinfection device using centrifugation technology to project micro-droplets of disinfectant, perfectly calibrated (5 to 10μm).

While SMR, through its integrator NORCAN, is very strong among industrials, logistics and e-Commerce operators, DEVEA is an expert in aerial disinfection, very present in pharmaceutical and food-processing companies.

Its virucidal process is the only one to be certified NF T 72-281, this standard being the reference for validating the effectiveness of device / product couples for manufacturers of this type of equipment. The hydrogen peroxide based product used has also already obtained marketing authorization, guaranteeing the effectiveness of the PHILEAS® system on 99.99% of viruses.

Through this alliance, NORCAN thus confirms its agility and adaptability in trying to recover after two months that have been very difficult for all companies. These qualities are essential to survive in a world that is increasingly unstable and uncertain.

E.E: At what stage is the market where you are currently active?

SMR: Mobile robotics is still in its early stage with many specific and inflexible applications: dedicated trajectories, heavy infrastructure and IT installations where humans are almost absent. Unlike AGVs which have dedicated trajectories, our AMRs are totally free.

E.E: What can you tell us about market trends?

SMR: Collaborative robotics is the future industry 4.0 standard. Market in very strong growth1 (> +20% / year) and in this Market, the AMR2 segment is growing even faster.

Our SHERPA® range is in the “non-dedicated” AMR category and is adapted for all companies, a lot of use cases including at the same customer’s premises.

SHERPA® is SAFE, COLLABORATIVE, INTUITIVE and MULTIPURPOSE.

On these characteristics, our robots are more efficient than AGVs or other AMRs.

Unlike AGVs, which have dedicated trajectories, AMRs are totally free.

E.E: What are the most innovative products marketed?

SMR: The complete range of robots is a high innovation for our company

Our solution: the SHERPA® family – a range of mobile and autonomous robots, which collaborates with humans, without any changes to existing facilities, for repetitive or non-repetitive tasks, easy to set-up and operate, covering a wide number of different applications.

Many benefits for our customers:

• Less pain and risks, and more ergonomics in the transport of loads.

• Much more productivity through the drastic reduction of low value-added tasks.

• More fluidity, greater flexibility and space savings by tending towards the «one-piece-flow» model.

• Solves the problem of manpower shortages and allows innovative transformation to factories 4.0.

In short: high operative and economical profits for our customers.

E.E: What estimations do you have for 2020?

SMR: Our target is to sell 100 robots this year. An ambitious, but realistic target for 2025 is 1.000 robots per year, a turnover of over 30 Mi€.