Sigma CapSeal, a brand of Electronics Devices Worldwide Pvt. Ltd., is a leading packaging machinery solutions provider with over 45 years of experience. The company has a presence in 85 countries and a customer base of 30,000 loyal patrons. Their product line incorporates a range of induction sealing and caps and closure machines. Industry-leading businesses from around the world trust their solutions to improve the shelf life of the products. The company’s solutions also help the products from counterfeiting, tampering, and adulteration.

Easy Engineering: What are the main areas of activity of the company?

SIGMA CAPSEAL: We are a market leader in induction sealers and cap and closure automation machines. We have a strong and dedicated team of 250+ engineers who deliver cutting-edge and cost-effective solutions. With the diverse industry experience of our experts, we offer solutions that deliver the best performance and uptime.

E.E: What’s the news for 2021 about new products?

SIGMA CAPSEAL: We have very recently launched two new machines – Sigma Neo 65 Induction Sealer and Lotion Pump Assembly.

Sigma Neo 65 is the latest addition to automatic induction sealers. The induction sealer has an IP 65 enclosure, which protects products from dust, oil, and water. It comes with a maximum line speed of 12 meters per min based on the size of the bottle and the cap.

The machine will fit into most production lines with no need for any modifications. The inbuilt castors offer mobility from one line to another. The machine is ideal for dry products like tablets, coffee powder, CBD powder, and much more.

The Lotion Pump Assembly is an Industry 4.0 IoT product. You can assemble all the 11 components like liner, housing, and spring in a single machine. There is a part feeding and assembly arrangement. It inspects every single part and also offers a leakage test.

E.E: What are the ranges of products?

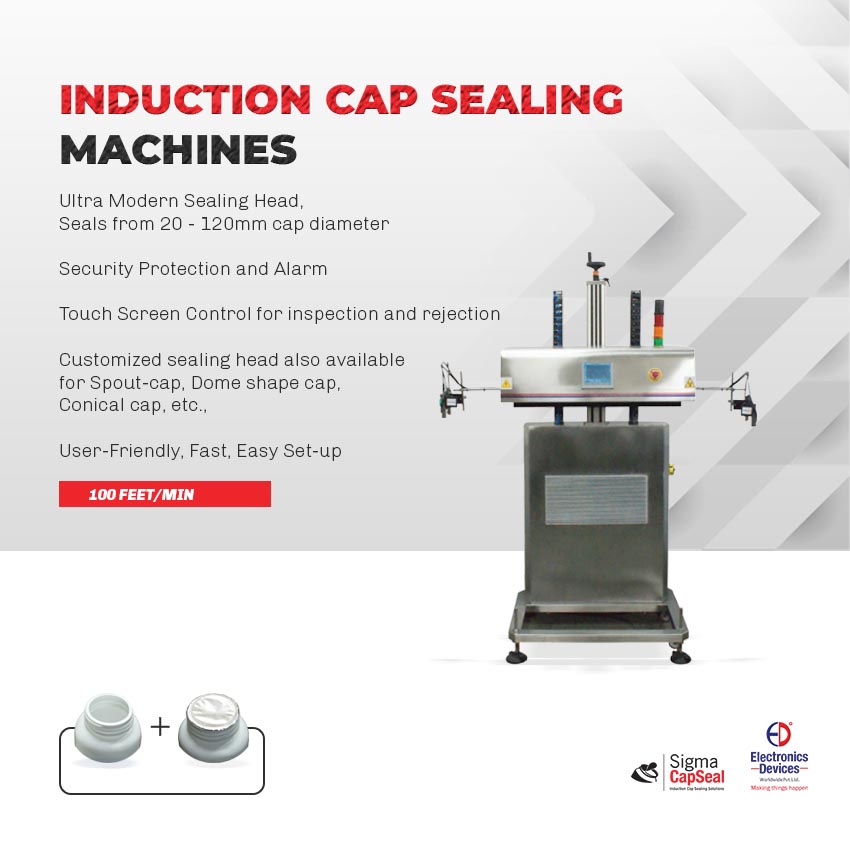

SIGMA CAPSEAL: We have two categories of products – induction sealers and cap and closure automation machines. Our induction sealer product range consists of eight different machines designed to suit the varied needs of businesses. These have a maximum line speed of 100 feet per minute.

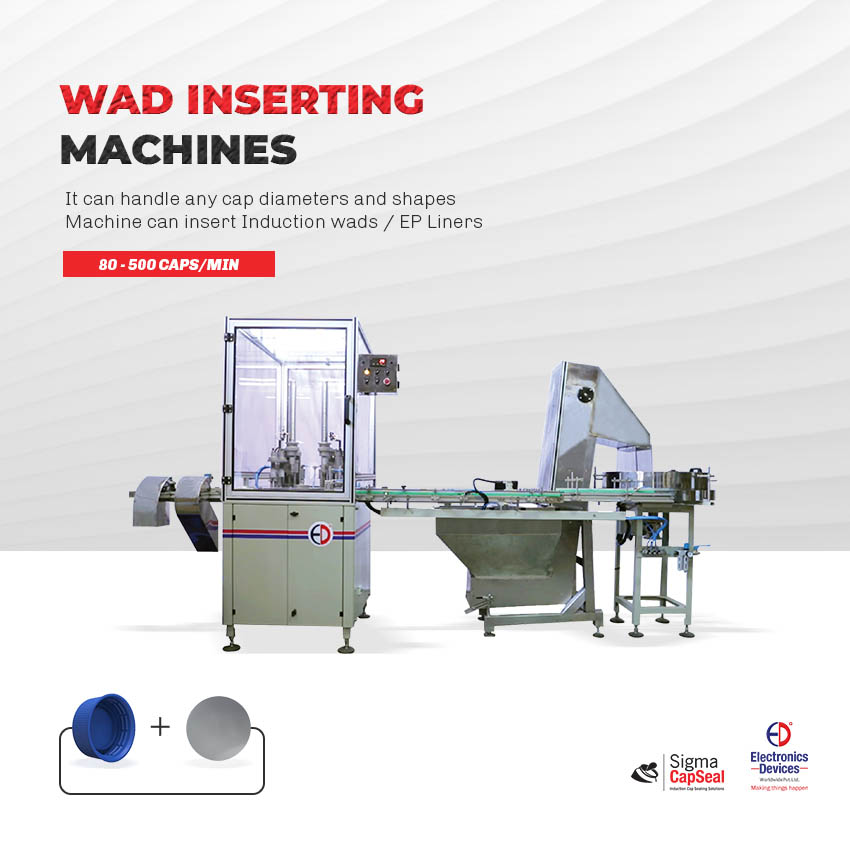

Talking about cap and closure automation machines, they are available in three types. The product range includes a wad inserting machine, flip-top cap closing machine, and cap lining machine.

Our product range finds its use in several industries like healthcare, personal care, dairy, F&B, specialty chemicals, and much more.

E.E: At what stage is the market where you are currently active?

SIGMA CAPSEAL: Our solutions find use by companies from more than 85 countries around the world. We have big tie-ups with businesses across Asia, Europe, and the US. India happens to be our primary business center. We have manufacturing facilities in India and the US.

2020 was disruptive around the world because of the coronavirus pandemic. But we have managed to move along without any issues. Our commitment to innovation and business expansion has helped us launch Sigma Neo 65 Induction Sealer and Lotion Pump Assembly very recently.

E.E: What can you tell us about market trends?

SIGMA CAPSEAL: The current market trends favor innovation and sustainability. We remain committed to solving the major issues related to packaging machinery. Our solutions are already helping businesses improve their production standards by making them fast and efficient. We will continue to innovate and introduce a new line of products that help meet the ever-changing demands of the packaging industry.

E.E: What are the most innovative products marketed?

SIGMA CAPSEAL: One of our most recent innovations has been in the induction sealing category. We have launched a universal head for induction sealers. Manufacturing businesses no longer have to worry about the varied length of containers. The universal sealing head can accommodate containers with sizes of 35-150mm.

E.E: What estimations do you have for 2021?

SIGMA CAPSEAL: We are almost halfway through the year. The first half has been quite busy for us with the launch of new solutions for packaging machinery. We expect countries to open up soon in light of the increased availability of vaccines. The pandemic has unfortunately brought a lot of disruption and grief to people worldwide. But we are hopeful all of that will change soon, and we get back to leading normal lives.