SIMCON is a German software manufacturer and professional services company, specialized in plastic injection, molding simulation and optimization. CEO Dr. Paul Filz founded the company in 1988 as a spin-off of one of the leading research institutes in the world, RWTH Aachen University’s Institute for Plastics Processing (IKV). Today SIMCON is run by him and his daughter Ines Oud.

Easy Engineering: What are the main areas of activity of the company?

SIMCON: We have been helping world-leading innovators get better, faster and cheaper injection molding results since 1988. Our sales and support network spans the globe from the US to China. Our customers are from many industries, including the automotive, aerospace, medical, electronics and consumer goods sectors.

E.E: What are the ranges of products?

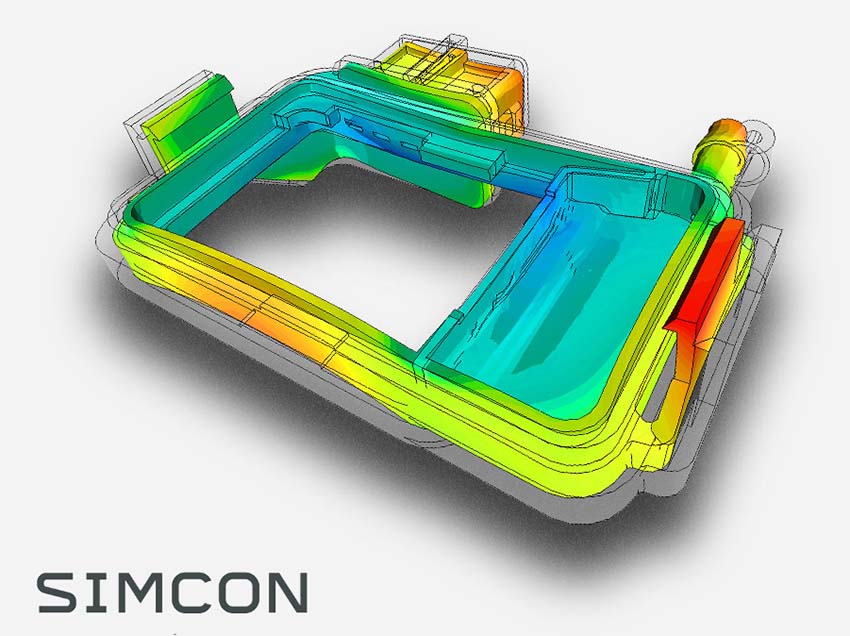

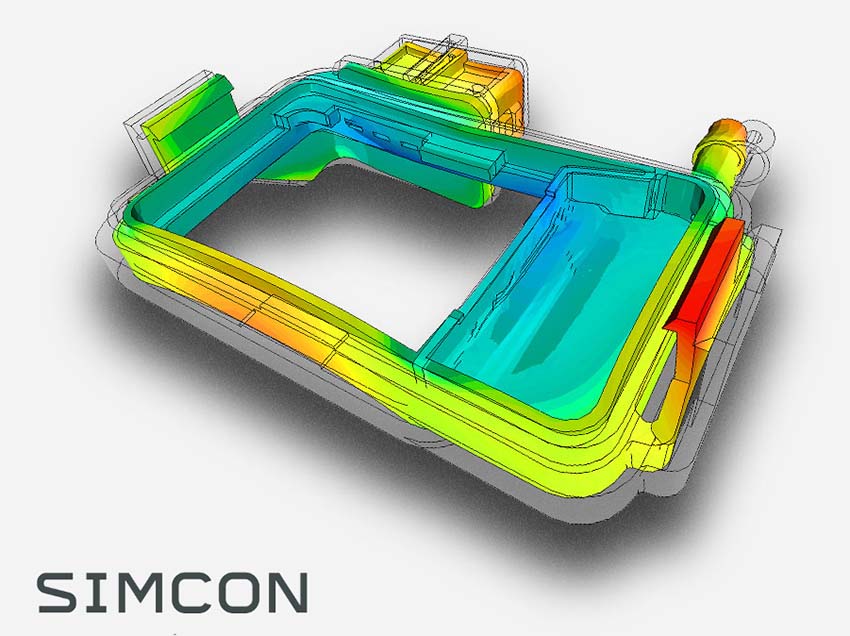

SIMCON: We offer simulation and automated optimization solutions, to help our customers design better parts, molds, and injection parameters. What we offer is tailored individually to what the customer specifically needs. That’s why our software CADMOULD is fully modular. Modules can be bought individually, or in economical packages. The “Fill-It” is our starter package that helps you anticipate the filling of the part, pressure distribution air traps and weldlines and so on. Our most popular package is “Engineer-It”. It additionally enables customers to simulate shrinkage and warpage, and demanding processes such as cascade injection molding or multi-component injection molding. It also includes our unique automation and optimization solution VARIMOS. VARIMOS automates setting up many design variants, simulating them, and interpreting the results. It helps users quickly understand the impact of design changes, and suggests an optimal design. To get going, VARIMOS asks the user three things:

- What are your objectives / how will you measure success?

- Which variables / parameters may VARIMOS vary, to achieve these goals?

- What are your tolerances and restrictions?

Based on the answers, VARIMOS will create a Design Of Experiments and automatically run these experiments as simulations. It then uses artificial intelligence to learn from the results and construct a model. This model captures how your variables affect your objectives. It then visualize the results, simply and interactively.

E.E: What’s the news for 2021 about new products?

SIMCON: We’ve got several improvements that help users work more efficiently with the software, and extend the results they get. We’ve created a new way to quickly and efficiently import not just part designs, but entire mold designs from CAD. We’ve also invested heavily into further accuracy and speed optimizations, included many new materials in our database, built powerful new interfaces and integrations with industrial CT scanning software and injection molding machines, included several usability enhancements for VARIMOS, and much more. Follow us on LinkedIn to get the latest news on new features, as we release them!

E.E: At what stage is the market where you are currently active?

SIMCON: Simulation has become the default way of working for the leading companies in plastic injection molding. We have seen a rapid increase in adoption of this technology. Anyone who wants to be competitive today simply cannot afford to have to painstakingly correct every mold by hand. The demands on plastic parts and molds are enormously high, and at the same time the costs must be kept as low as possible. In most cases, the purchase of simulation software pays for itself in less than 6-9 months, even with only 3-5 molds per year.

Our most successful customers simulate multiple variants of every part they design. We think the next level of maturity is to automate variant analysis. Customers will invest the gains in computation power and cheap storage into simulating more variants, analyzing them systematically, and optimizing. And they will automate more of the tedium of setting up all of these variants. By exploring more possible designs, you are bound to learn more and find even better solutions. This is what our VARIMOS solution helps users achieve.

E.E: What can you tell us about market trends?

SIMCON: There are three important trends at the moment.

The first trend is clearly moving in the direction of automation and optimization. The demands placed on plastic parts are becoming ever higher and engineers often simply no longer have the time to set up and carry out each simulation laboriously by hand, one by one. Modern companies simulate multiple variants for each part, and they run these variant simulations in parallel, instead of sequentially. They simply cannot afford to waste time. Solver speed and parallelization ability are crucial for this way of working.

Another trend relates to the subject of cross-functional collaboration. When a part designer designs a part, but the mold later runs into feasibility issues, there will be unnecessarily long correction loops. You can easily avoid these loops if the part designer, the moldmaker and the injection molder work together from the beginning. They should work simultaneously and collaboratively, instead of sequentially. This has a process and organizational dimension, because it means that working teams should be structured by project, not by department.

The third and probably most drastic trend is the move towards a circular plastics economy. The world simply cannot afford to continue using plastics without thinking through the entire life cycle. We expect increasing regulation that puts more requirements on the use of recycled materials. This is a technical challenge, because current recycled materials behave less predictably in manufacturing. There is also a supply security issue, as the availability of recycled materials can also be less predictable. Manufacturers’s designs and processes will need to take this variability into account. Our software can help customers anticipate and deal with this variability.

E.E: What are the most innovative products marketed?

SIMCON: We think that the current frontier of innovation happens not only at the individual product level. It’s their combination that makes order-of-magnitude improvements. By building end-to-end digital chains that interlink multiple digital solutions, you can innovate quite substantially. You can combine CAD, injection molding simulation, FEM simulation, quality measurement, etc., to build overarching automations and optimizations. The combination is more than the sum of its parts.

For this reason, we are investing heavily into interfaces to adjacent software. For example, you can set up quality measures in CAD, using PMI (product manufacturing information), then use these measures as optimization targets in our software CADMOULD and VARIMOS. Our software sends warped simulated geometries to an industrial CT scanning software by Volume Graphics, retrieves the quality measures from there, and uses them in model construction and optimization. That way, simulation results are evaluated the same way as real-world results. Suddenly, quality management and engineering speak the same language. Compatibility enables such process innovations. Better collaboration means better results.

E.E: What estimations do you have for 2021?

SIMCON: We are extremely pleased with the development of the market. We have seen many customers applying the lessons from the pandemic – namely that it is important to be able to respond quickly to changing market environments. They are investing into speed, agility, and the ability to quickly pivot. Faster and better product and manufacturing design helps companies respond more quickly to change. Our product helps with this, so we are benefiting from this adoption of new ways of working. We are very optimistic that this development will accelerate further.

We are also very much looking forward to having in-person fairs and events again – provided vaccinations proceed as planned and their efficacy remains high despite the evolution of virus mutants. At the moment, we are optimistic that in the fall and winter, the worst of the pandemic will be behind us in Europe.

If you want to learn more about us visit www.simcon.com or contact our local sales and support partner Mr. Radu Canarache radu.canarache@inicad.ro.