Single Use Support offers solutions in fluid management and cold chain logistics for the whole biopharmaceutical industry. Highly valuable drug substances are filled, frozen, stored, shipped and thawed in so-called bio process containers (or single-use bags). As process solution provider, Single Use Support takes care of the optimization of manufacturing processes, for example, through reducing product loss of bioprocess containers by enclosing them in a protective shell.

Further to this, Single Use Support has expanded into the Cell & Gene Therapy space to offer solutions in the fill and freeze of sensitive therapies.

The product portfolio has evolved into an end-to-end process to safely handle liquid drug products – irrelevant of volumes, bag manufacturer, and requirements.

Furthermore, experts provide technical support, qualification, validation and documentation, and extensive after-sales services.

Interview with Roland Jenewein, CTO at Single Use Support.

Easy Engineering: What are the main areas of activity of the company?

Roland Jenewein: We produce both platform systems and sterile consumables for the biopharmaceutical and Cell and Gene therapy spaces. The areas of application are within clinical studies in labs, commercialized vaccine manufacturing in large production sites and regenerative medicine for personalized cell and gene therapies at small volumes. This requires a scalable tech transfer from small to large bulk drug substance manufacturing.

At Single Use Support we strive at finding modular, scalable, compatible and independent solutions in fluid and cold chain management to enable customers to achieve flexibility and seamless process steps.

E.E: What’s the news about new products?

R.J: We seek to constantly improve pharmaceutical fluid management and cold-chain logistics and therefore continue to launch new innovations. Single Use Support stands for customer-focused innovative solutions surrounding single-use systems. I can highlight two new products:

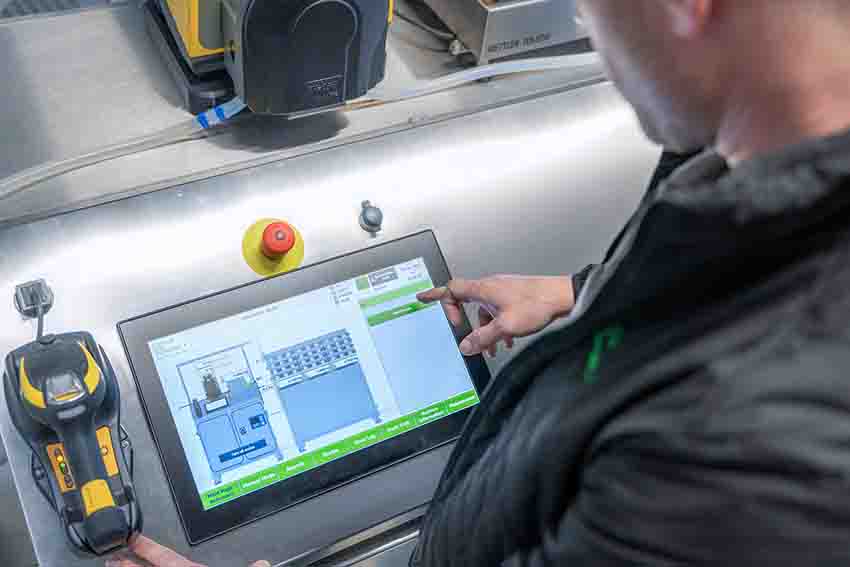

We have equipped our platform system for automated aseptic filling of liquids into single-use bags with advanced sealer & stepper pinch valves. These enable a dropless and sterile disconnection of individual bags after the filling process. The integration of such valves improves decoupling of single-use assemblies largely in terms of process time, errors through lack of manual interference, and safety.

Cryopreservation of cells require ultra-cold temperatures for storage – the industry standard is at approx. -180°C. Upon custom requests from biotechnology companies Single Use Support has engineered the first cryogenic controlled LN2 freezer for the use in regenerative medicine.

E.E: What are the ranges of products?

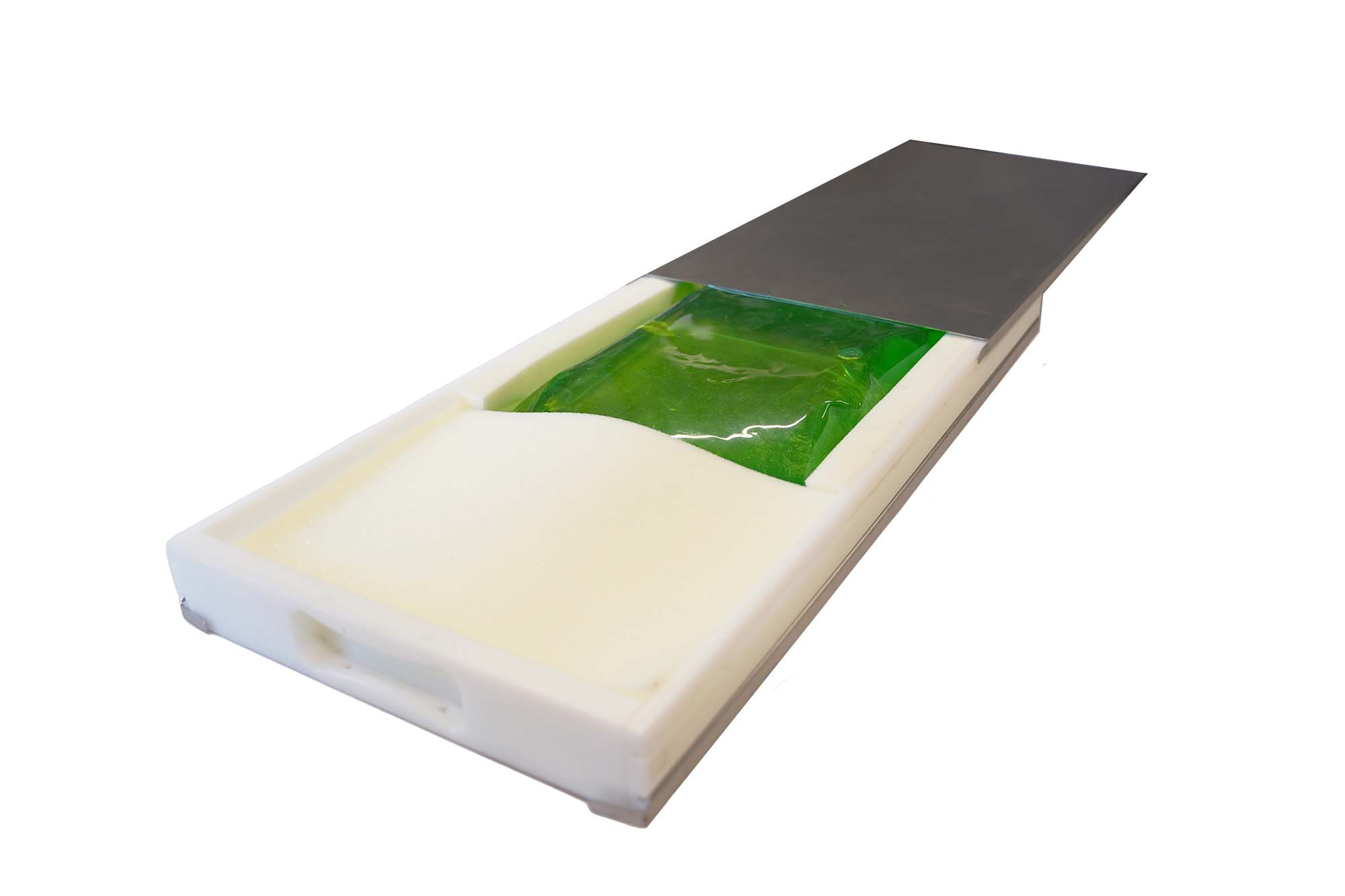

R.J: RoSS® – abbreviated for Robust Storage and Shipping – is at the core of all technologies. It is a protective shell for all available single-use bags to reduce product loss towards 0%. Thanks to its surface at top and bottom out of stainless-steel the heat transfer with plate-based freeze-thaw platforms allow fast and homogeneous freezing. Other than slow freezing in conventional chest blast freezers, plate freezers accelerate the manufacturing process and avoid the event of cryoconcentration which harms the quality and viability of proteins.

RoSS.FILL is an automated fill-drain platform into different bioprocess containers and bottles. It allows maximum flexibility and scalability of both the filling and draining process. It is possible to fill unlimited volumes per batch with a speed of up to 300 liters per hour.

RoSS.pFTU is the already mentioned plate-based freeze-thaw platform cooling down to -90°C that is fully scalable and compatible with all batch sizes and bags from all established manufacturers.

Further products for cold chain storage, transportation, shaking, homogenizing and more round off the current portfolio.

E.E: At what stage is the market where you are currently active?

R.J: We still see technological deficiencies in the drug substance handling in the area of aseptic filling, freezing, thawing, transportation, draining, storing, mixing, etc. Therefore, we seek to improve technologies around pharmaceutical liquid transfer and hence patient safety. Providing our independent process solutions, we disrupt the until now very siloed market: To date, having in use one specific type of primary packaging for liquid medicine is limiting flexibility in further cold chain logistics in terms of speed, quality and safety. With our bag-independent protective shell we are the first to standardize the manufacturing process, no matter what type of single-use bag the manufacturer prefers. This opens doors for various companies involved in the development and manufacturing of bulk drug substances and advanced therapies, such as cell & gene therapy.

E.E: What can you tell us about market trends?

R.J: We observe different trends in pharma manufacturing. One is the growing demand for mRNA vaccines after their breakthrough with COVID-19 vaccines. Another market trend is the bigger focus on so-called ATMPs: advanced therapy medicinal products. More and more personalized cell and gene therapies are authorized by the FDA, offering improved treatments for patients with specific diseases like leukemia (ALL).

For both market trends a sophisticated fluid and cold chain management will gain importance.

E.E: What are the most innovative products marketed?

R.J: Our sealer pinch valves introduce a new generation in decoupling single-use tubing assemblies that is reducing manual process steps and hence the risk of human operative errors. This novel integration of these valves into the filling platform system enhances flexibility even further for the automated and sustainable filling process.

In general, I would like to point out our freezing and filling technologies in the space of cell & gene therapy. Based on customer requests we have created platform solutions to freeze below -150°C with LN2. And with our RoSS.FILL Cell Gene Therapy scalable aseptic filling it is now possible for volumes down to 10 ml and even below.

E.E: What estimations do you have for 2022?

R.J: We will continue providing biopharma with innovations. Our approach is to pioneer the biopharmaceutical industry by launching new products, services and process solutions. With their wide range of applicability, we are sure that we will foster an even stronger position with new customers.

Single Use Support

LinkedIn: https://www.linkedin.com/company/single-use-support-gmbh

Youtube: https://www.youtube.com/c/SingleUseSupportGmbH

Website: https://www.susupport.com/