SL Laser was founded 1988 in Southeast Germany (Bavaria) in the town called Traunreut. SL is producing laser projection or positioning systems for the industry. The headquarter is in Traunreut with offices in France and the USA. Further SL works with a lot of resellers and agents all over the world. In Traunreut SL is producing and developing the laser products and the software. With more than 7000 installations worldwide SL Laser has the expertise to provide solutions for the different branches. With their engineers and services, they can provide on-site or remote assistance help.

Easy Engineering: What are the main areas of activity of the company?

SL STARTS: SL starts with first installations on CNC router machines and later extended in the area of textile industries, especially on cutters for the nesting and later on the woodworking area, like truss, glue lam and timber frame manufacturing. Later prefab companies, manufacturers of precast parts saw the advantage of that system to use it on long tables or carousel systems to project shutters, inserts and frames on the tables and to show the workers the placement of that parts. The computer-controlled laser system with the corresponding software allows to transfer working plans and measuring points even for large-scale or angled mounting surfaces accurately as well as in a time and cost saving way. In the field of precast concrete construction the firmly fixed laser enables exact positioning of formwork, embedded parts and reinforcement.

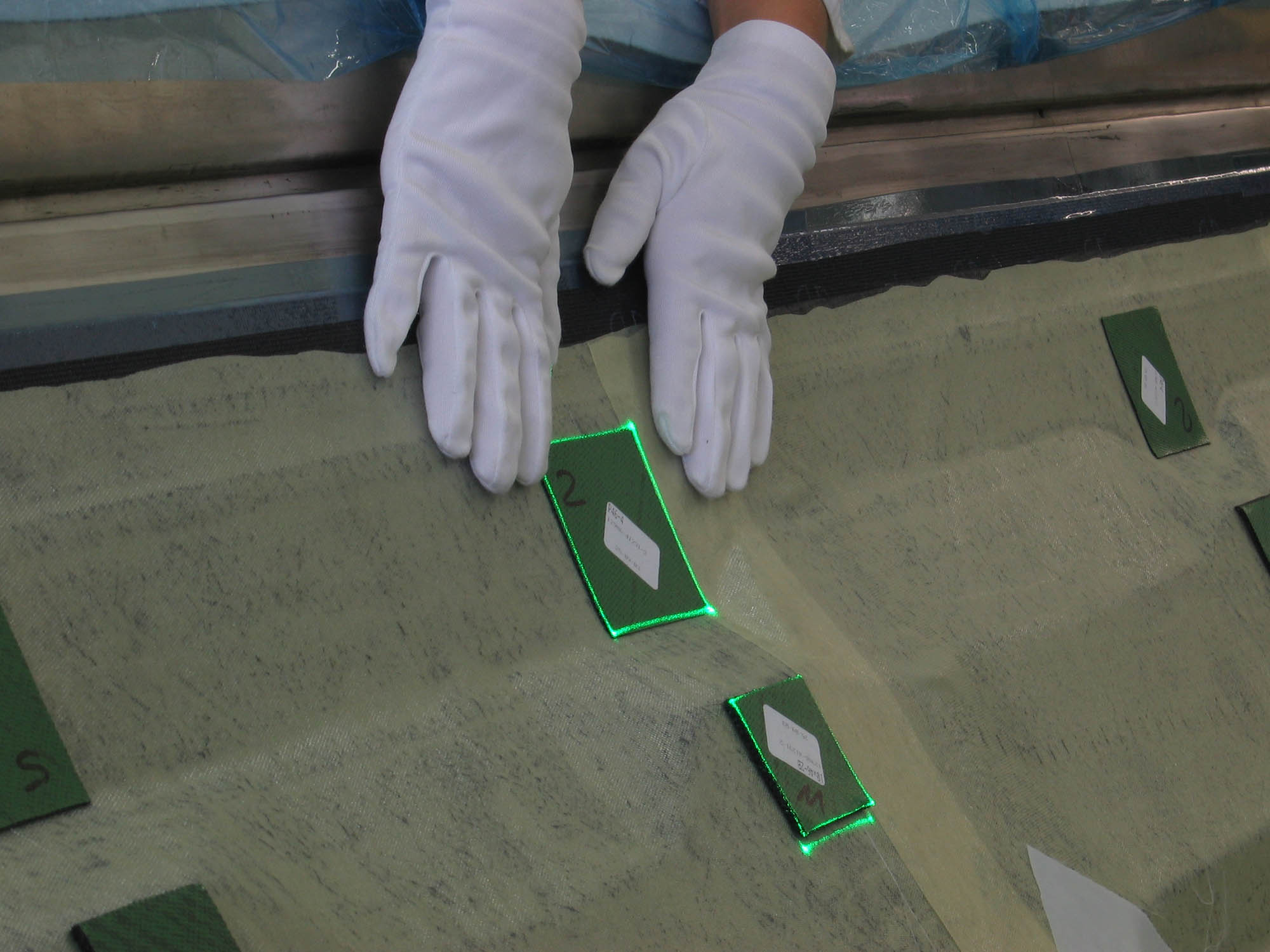

On 1999 and 2000 the company changed the owner. In that period SL starts a new era of business. The use of the laser systems in the composite industries. A lot of aircraft manufacturers and sub suppliers uses the laser projection system for the hand lay up process of prepreg material on tools. Later the saw the advantage of the visual help on assembly processes. The use of the laser head to position brackets, holders and click bond parts on different frame structures gave the companies the security to have a continuous workflow to eliminate mistakes and to project 1:1 CAD drawings on different surfaces.

The range of the branches that are using our laser positioning systems starts from a joinery goes to timberframe house producers, truss companies to precast concrete manufacturers and to the aerospace producers. A new market is the steel branch, especially companies that are using the welding process. There we show the position of the welding parts. The laser beam shows the operator the outline of the part in the right angle for the later welding.

E.E: What’s the news for 2021 about new products?

SL STARTS: Our main product is the laser head ProDirector 6+ and the small unit ProDirector XS2. That models are projecting faster and with less flickering. We offer next to the hardware and application the software that the customer needs. That could be a software for 2D applications or for 3D. New on that kind of software is that we can provide individual solutions for the customers. Next to that, we offer a simple to use software to create laser lines. That software is called SL Assembly.

E.E: What are the ranges of products?

SL STARTS: Mainly we produce laser projection systems for the industry. Further we have our software that used for the lasers, to project different data formats on different surfaces. Another system that we have is the ProCollector, that is a measurement system to collect points make drawings of interiors, stairs, walls and other important things if you need later to assembly in a boat the furniture for example. At last we have our cross and line lasers for different use of alignment or fixing.

E.E: At what stage is the market where you are currently active?

SL STARTS: The woodworking market is growing, like timber frame and truss, the same the prefab of concrete. The composite market, especially in the aerospace industry is now decreasing, the reason is the pandemic situation. Another branch, like the steel industry is in a stuck state. Some of them have work some of them less. That depends in which area they are working.

E.E: What can you tell us about market trends?

SL STARTS: Market trends are difficult to explain. Some of the customers needs to be safer in the production of parts. That means less costs of repairs in case of mistakes in the production. As example that I can mention is if one customer is producing with a wrong alignment the parts and the check of the quality controls reveals the error it is more expensive to correct that mistake. The customers start using more and more the digitalisation options. Starting from CAD provide that CAD to the production, eliminate the errors in that way. Use of more Industry 4.0 that has more reasons. Reliable work, less mistakes, the advantage that workers can handle with easy steps the work, if the customer has not the option to get more qualified workers in the production.

E.E: What are the most innovative products marketed?

SL STARTS: In our case the laser positioning system with the software. Easy to use for the workers and you need the engineering in preparing the work for the production. From the beginning, creating the CAD-Model to the projection of 1:1 of the CAD parts on the tools. A continuous work flow with confirmation of each work step.

E.E: What estimations do you have for 2021?

SL STARTS: 2021 would be a year of challenges. At that time, we see some market areas growing and some not, like the aerospace industries. The construction and building area are growing. We will see how long that will continue. I think after the pandemic years 2020 and 2021 we will see that the transportation industry will grow more than in the pandemic years. That could be a restart for the aerospace industry in 2023 and for other transport options like busses, trains and cars.