SmartFluidPower specializes in the simulation of fluid power components and systems. The company’s goal is the development of lean, intuitive simulation tools, dedicated to product design, analysis, and calculation. Their core product is the simulation software based on the OpenModelica open-source environment. Its libraries are developed in Modelica, an object-oriented language created for modelling complex multi-domain physical systems.

In this type of simulation (named lumped parameters) the physical systems are represented by systems of differential and algebraic equations. Unlike simulation with distributed parameters (such as FEM and CFD), the company considers the behavior of phenomena with time to analyze the dynamics of the systems.

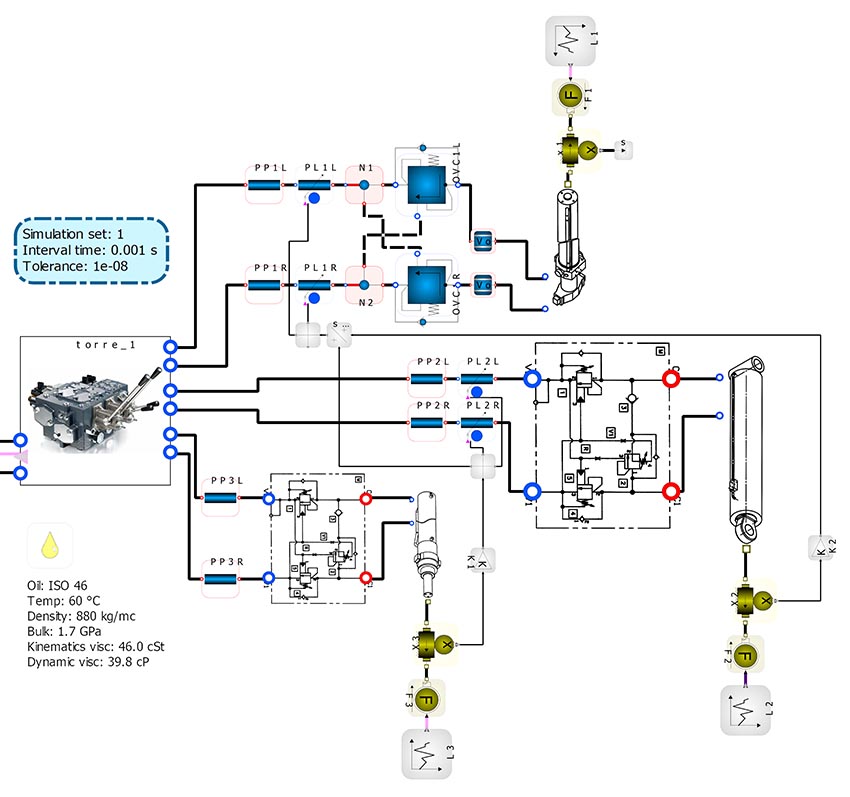

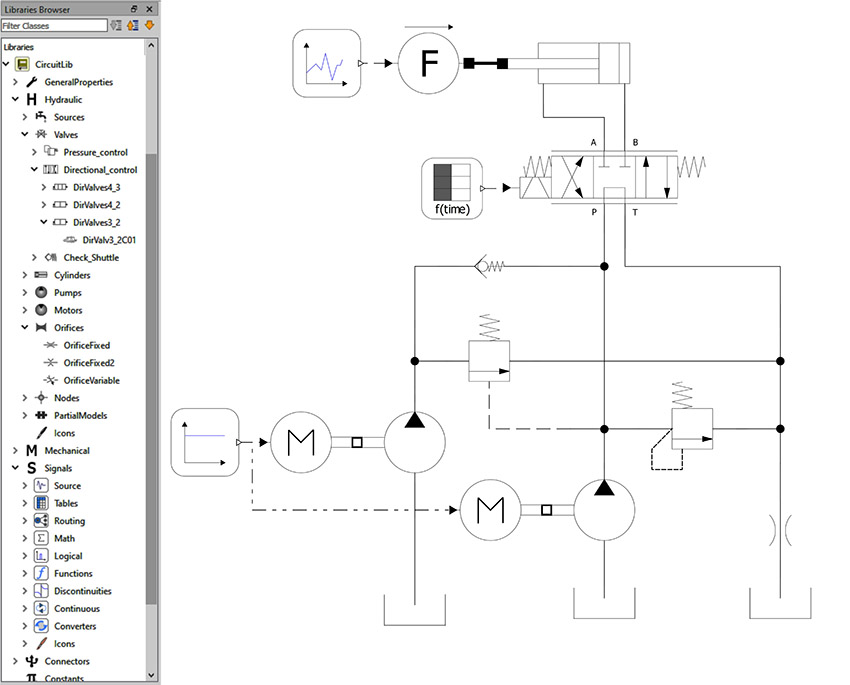

This language uses the block approach that starts from a functional diagram of the system. The icons in the library represent physical components or a part of it (i.e. motor, valve, mass, etc.), while the connection lines define the physical coupling between the elements. By assigning the parameters and the operating conditions, the model is automatically translated into a set of equations, that are solved by the algorithms available in OpenModelica.

Interview with Giovanni Cillo, President of SmartFluidPower.

Easy Engineering: Which are the most innovative products / services and what special features do they have?

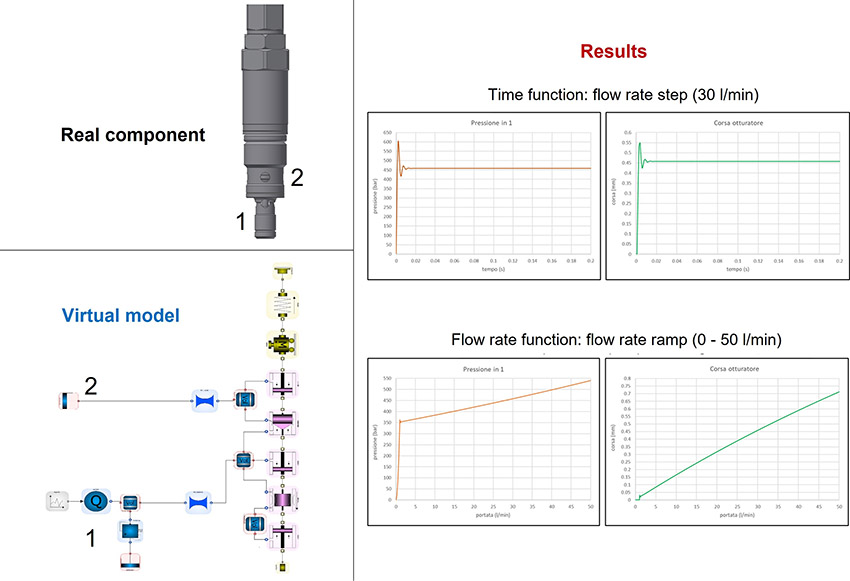

Giovanni Cillo: Our most innovative product is our simulation software. It is designed to enable users to create a virtual prototype (Digital Twin) combining the elements in the libraries, in order to simulate functionality and performances before building the physical product.

Different levels of complexity are possible:

- the advanced library allows the dynamic simulation of hydraulic components and system;

- the logic library allows users to analyze systems from a functional point of view.

All simulation results can be graphically displayed and analyzed.

In addition to that, we provide services that help integrate functionalities and improve the product user experience even to those new to the simulation environment.

E.E: How important are these features for the users in their work?

G.C: This component-based approach creates a single model for each of the required elements that can be then connected to create different combinations. We have created functional packages that are recognizable and combinable. The modelling is “physical” in the sense that the user can recognize the real components by looking at the virtual elements. This way, the designer can simulate autonomously, with the same ease of working in the CAD environment.

We provide services to support such simulation work. Our most innovative service is the development of custom external interfaces for parameter modification, simulation and data export. The software is thus usable at different degrees of complexity and at every company level.

E.E: How important is innovation in your field?

G.C: The fluid power industry aims to develop hybrid hydraulic and electric solutions for increasing efficiency, performance, and safety.

To reach this goal, the hydraulics components need to be redesigned to improve energy efficiency. Moreover, simulation tools need to be employed to validate hybrid systems virtually, monitor their performances, and increase their life cycle.

By achieving these strategic objectives, the fluid power sector can gain competitiveness. These objectives are also a result of the increase in the specialist know-how of its employees.

In this highly competitive market, a product like SmartFluidPower software can help a lot. It makes product innovation much faster, by enabling companies to identify the best solutions quickly and effectively.

E.E: How do your products / solutions impact cost effectiveness for the users?

G.C: The Digital Twin allows functional analysis, performance verification and modification of the design parameters to ensure optimization.

This approach is fundamental in some phases of the product’s life, such as prototyping and fine-tuning. It allows users to test different combinations of parameters quickly and inexpensively. By minimizing the number of physical prototypes, we reduce costs and timelines.

E.E: What kind of work do users who use these products / services do?

G.C: Fluid power includes all the systems that generate, control and regulate power using a working fluid. This discipline is at the core of many technologies, perfectly integrated with electronics and information technology, and it is used in many industrial and mobile applications, such as automotive components and off-high-way vehicles.

SmartFluidPower’s target are organizations that struggle to dedicate resources to research and development, in particular to virtual prototyping and simulation.

In such organizations, the traditional “trial & error” design method requires the creation of many prototypes, with a huge expenditure of time and resources. This approach is no longer competitive, as the global market requires quick innovation and energy savings.

E.E: How do your products increase profitability for users?

G.C: Using virtual simulation limits tests and prototypes by predicting the component behavior. This approach in turn allows companies to remain competitive in a fast-paced market.

Furthermore, our products are not aimed only at designers. Their functionality can be used at many distinct levels of complexity within the organization, through customized user interfaces.

E.E: How do your products / services differ from other types on the market?

G.C: The following sets us apart from the competition:

Our set of supplementary services to maximize the potential of the software. We create customized models for our customer’s needs. We provide external software interfaces with different degrees of complexity. We integrate with other types of simulations (FEM, CFD) to detail the results of dynamic models. We also organize modular training courses, from beginner to advanced.

The ‘component based’ simulation approach allows you to simulate multi-domain systems. Which means you can integrate different physical worlds together such as hydraulic, mechanic and controls.

The use of an open-source platform as a calculation engine reduces the initial investment. Moreover, it makes the integration with other commercial software possible.

Our team is highly specialized, and we can provide targeted and efficient solutions

E.E: How do your products help solve users’ problems?

G.C: The Digital Twins allow you to test different combinations of parameters quickly and inexpensively, while optimizing their performance. This way, we minimize the prototypes and the experimental tests.

Often, these systems are very small and complex, which makes it impossible to observe the internal phenomena. The virtual model makes it possible to access all the internal variables and to better understand the product.

There is also an important social impact of the approach promoted by SmartFluidPower.

By keeping track of all the issues during the creation process, it becomes easier to share the know-how within the organization.

By making our product flexible and accessible, we aim to help integrating simulation assisted design into the daily life of companies in the sector, resulting in time and cost optimization.

E.E: What products / solutions are you going to launch in the future?

G.C: We plan to enhance our existing products and develop new products.

We are working to increase the functionality of the components in the library (for example the integration of the simulation of heat transmission) and improve the user experience, with an animated display of the results.

We have different versions of the software libraries in our pipeline, to increase the levels of specialization and facilitate access to the simulation by all types of company users. We also plan to add libraries to connect and integrate other physical worlds with the hydraulic one, such as the electric and magnetic domains.

Linkedin: https://www.linkedin.com/company/smartfluidpower

Facebook: https://www.facebook.com/smartfluidpower

Twitter: https://twitter.com/SmartFluidPower