Founded in 2009 as a spin-off of the Fraunhofer Institute for Solar Energy Systems (ISE), SolarSpring GmbH – membrane solutions has evolved into a global expert in the field of membrane distillation offering an innovative waste- and drinking water treatment technology. The mission of SolarSpring is to develop and operate sustainable water solutions that can help people around the world.

Because of the vicinity to the institute, SolarSpring benefitted from the participation in a variety of international development aid projects, which eventually resulted in the development of water treatment modules and plants.

Now, 12 years later, the company is in a position to respond to a large range of customer requirements thanks to highly specialized personnel and a versatile technology portfolio. Due to the high portion of in-house production individual adaptations to customer requirements can be carried out in an efficient and flexible manner.

Easy Engineering: What are the main areas of activity of the company?

SolarSpring: SolarSpring’s business can be divided into two parallel but different approaches. One focuses on the supply of purified water to people. The other one contributes to the development and design of services that increase energy productivity and improve material cycles in different industry sectors. The company focuses on tailor-made systems to find solutions for the challenges related to wastewater treatment and drinking water treatment. The company aims for reduced use of chemicals by designing systems with minimal or no chemical consumption. For instance, the membrane distillation filtering process is designed to treat wastewater with its own process waste heat.

SolarSpring has a very consumer-oriented approach with tailor-made solutions including energy-savings for customers. SolarSpring actively encourages and helps customers change towards a more sustainable behavior. Customer loyalty is heightened by a competitive price management and high standards in quality and service. Flexible and quick response to the circular economy market is the guideline of SolarSpring, and the company’s slogan is: “Pure water, our passion”.

By recycling contaminated wastewater, the environment can be protected, CO2 consumption can be reduced, and groundwater contamination can be prevented. Additionally, SolarSpring’s industrial customers can reuse their process water within their own production and, if necessary, the added raw materials or chemical inputs can be recovered and, depending on the initial situation (quality of the filtration result), returned to the process. The available process waste heat can also be excellently incorporated into the membrane distillation in order to power the process. This closed economy circular loop is a win-win situation. In addition, the payback period is around 2-3 years from the customer’s point of view, depending on the plant and volume.

The products for drinking water treatment are comparatively standardized, have straight sales processes via partners and will need no or only minor adjustments for the clients. Accordingly, this creates a continuous revenue stream which is expected to continue its growth. For the industrial water treatment sales cycles are longer as the products are tailor-made for the specific application. Accordingly, there are greater fluctuations in turn-over. At the same time within this business unit also more services are requested for engineering or maintenance. To balance the revenue, stream a new business model is also planned – contracting.

E.E: What’s the news for 2021 about new products?

SolarSpring: In 2021, SolarSpring released a larger drinking water system. The previous size produced 2000 l/h and the new size, the PRO3000 produces 3000 l/h.

For the industrial water treatment systems, SolarSpring has been working on a new model type that will be easier to upscale, more modular and much more cost effective regarding capex. The details are still confidential but we hope to release by the end of 2021.

E.E: What are the ranges of products?

SolarSpring: SolarSpring offers high-quality, future-oriented membrane and ultrafiltration systems for this area of application, which actively supports their customers in the elementary task of ensuring an economical water supply.

Membrane solutions

SolarSpring is an innovation leader in the field of membrane distillation and intends to maintain this position in the future. For SolarSpring, innovation means continuously improving and even revolutionizing its own processes, products, and services. From visionary ideas, the company develops smart solutions and innovative novelties that set new standards in the industry.

With our experience and the connection to Fraunhofer ISE (science), we are among the absolute experts in membrane distillation. In addition to the continuous further development of our processes, modules, products, and services, we regularly participate in national and international research projects. With our research projects and partly publicly funded projects, we specifically investigate focal points that we regularly redefine due to current developments in technology as well as questions that arise due to the needs of our customers. For example, together with our customer Khalifa University in Abu Dhabi, we created an “MDLab” with a module made entirely of high-quality transparent Plexiglas. These customers have had a scientific question about how the influence of sunlight affects the process of membrane distillation.

The special hydrophobic and microporous membrane allows only vapour but keeps liquid away. In this way clean water is separated from the wastewater, which at the same time is concentrated.

The frequency and duration of cleaning depends on the process and product properties. In addition, a low chemical effort is necessary. Special high-temperature membranes allow cleaning up to 85 °C. For the economic evaluation of membrane cleaning, not only the direct cleaning costs but also the subsequent energy costs must be taken into account. Careful membrane cleaning is therefore a major factor in the economic success of a membrane process.

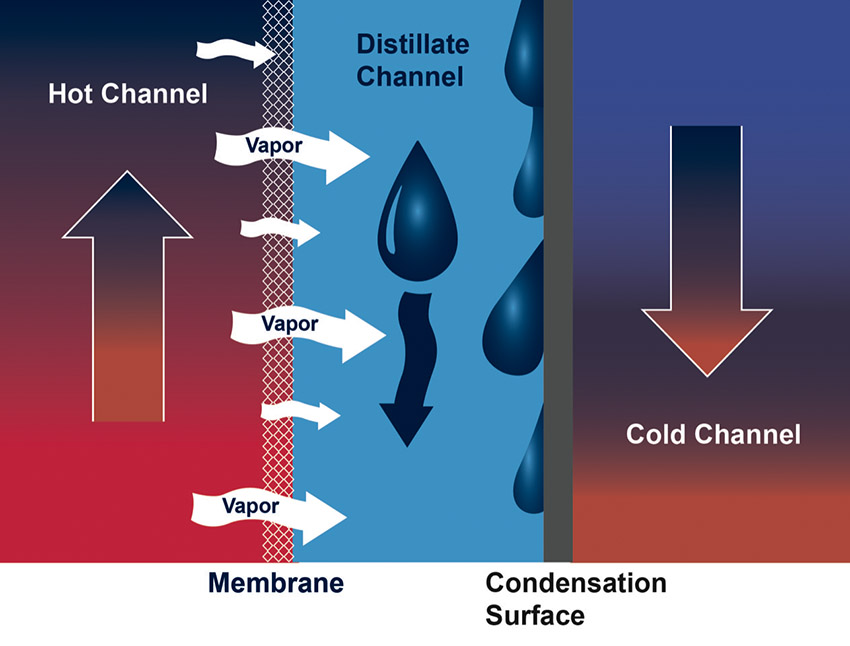

How Membrane Distillation works (Source: SolarSpring GmbH)

A membrane material which is both hydrophobic and microporous separates the liquid from the distillate but allows vapours to pass. The driving force for the distillation is a temperature difference, or partial vapour pressure respectively between an evaporator and a condenser channel. In between the hot and cold channel lies the distillate channel, which is separated from the other channels by a condenser film towards the condenser channel and a membrane on the evaporator side. As only vapours can pass the membrane a highly pure distillate is generated. The process operates at low temperatures of 35-95 °C and at ambient pressure, which reduces operational and maintenance costs.

Depending on the application, one of five different membrane distillation channel variants are implemented:

● Permeate Gap MD (PGMD);

● Direct Contact MD (DCMD);

● Air Gap MD (AGMD);

● Vacuum MD (VMD);

● Vacuum Air Gap MD (VAGMD).

Ultrafiltration

The drinking water filtration systems are a smart combination of 5 stages: An Ultrafiltration module, a sand filter, a disk filter, an activated carbon stage and an Ultraviolet-Disinfection unit. Interaction between the stages is synchronized and fully automatic – self-sufficient cleaning cycles enable a constant and smooth operation.

Ultrafiltration: used as main treatment to remove colloids, bacteria, and viruses from ‘dirty’ and microbiological contaminated surface water or well water.

Media Filter: used as a pre-treatment to remove e.g., iron, manganese, arsenic, hardness, etc.

Activated carbon filtration: used as post treatment to improve the taste and smell of the purified water. Activated carbon removes dissolved organics and some heavy metals.

Ultraviolet-Disinfection: used as a final treatment and a second security step after the drinking water storage. UV radiation can deactivate bacteria and viruses in order to guarantee a reliable protection against recontamination of the stored drinking water.

Different purification steps of Ultrafiltration Systems of SolarSpring GmbH

Products

Purification Units

The mobile system is a compact water purification system with integrated pump and battery for mobile application:

• max. 5 m³/day

• treatment: UF

• operation: inline or with storage

The economic system is a wall- mounted water purification systems mainly for inline application

• 6 – 21 m³/day

• treatment: UF

• operation: inline or with storage

The complete system is a fully equipped water purification system with multi barrier system design, mainly for storage application:

• 6 – 1,000 m³/day (modular design)

• treatment: UF+ACF+UV

• operation: inline or with storage

Membrane Distillation units

- The MDLab is a fully automated, 24hour operation

- Lab unit for investigations in various MD

- Configurations.

The MDIndustry units are customized for the application of the customer.

Portfolio

SolarSpring offers solar powered solutions for decentralized drinking water treatment and integrated membrane distillation systems for the industrial sector. The industrial solutions include:

● Recycling of precious metals such as e.g., gold and palladium;

● Zero Liquid Discharge and Minimum Liquid Discharge for e.g., Brine Treatment of RO-Units;

● Food and Beverage; gentle concentration of sensitive ingredients;

● Sewage treatment plants; reduction of CO2 emissions and production of fertilizer;

Depending on the area of application, SolarSpring’s systems can already be applied for treatment capacities as low as 0,1 m³ /day up to very large units.

Services

Customer-oriented wastewater analysis and plants developed according to customer requirements

Industrial wastewater from e.g., chemical, galvanic industry, textile industry or mines product manufacturing must be managed with care, using the appropriate industrial wastewater treatment process. SolarSpring is able to analyze different wastewater from different branches and provide recommendations for the most suitable and cost-effective industrial wastewater treatment processes to meet the specific treatment needs.

R&D

SolarSpring is also a frequently requested parter in research projects and offers contracted studies, trials and developments.

E.E: At what stage is the market where you are currently active?

SolarSpring: The market for solar powered drinking water systems is fully established and SolarSpring also works with distributors for improved access to non-European markets.

The industrial wastewater treatment sector has long investment cycles and higher volumes per sale so that lead times are typically longer. Successful system deployments often start with pilot trials to get the new users comfortable with such an innovative and new technology before implementing on a full scale.

E.E: What can you tell us about market trends?

SolarSpring: The reuse of municipal and industrial wastewater and process fluids is becoming increasingly important worldwide to ensure the economic and ecological availability of water.

Key factors that are driving the water and wastewater treatment equipment market include increasing demand for clean and processed water due to rapid urbanization, expanding population, and infrastructural development. This is coupled with stringent regulations by governments for wastewater emission.

Market Drivers

The global population tripled in the 20th century, which resulted in a dramatic increase in the usage of water. This, coupled with a 55% drop in available freshwater since 1960, puts a massive strain on available resources in our increasingly industrialized and thirsty world.

Allowing inadequately treated wastewater to flow into waterways means that harmful chemicals are mixing, causing unknown reactions. This requires remedies to handle water pollution if the wastewater shall be available for use again.

Wastewater treatment onsite, at an industrial facility, stops the issue at the source, preventing the effects of environmental pollution from developing. Many companies are now taking a further step and are performing wastewater recycling onsite.

For example, the manufacturing of textiles can take up to 200 tons of fresh water per ton of dyed fabric. Thus, there is inevitably a vast amount of wastewater produced in the process.

Industries producing a great amount of wastewater are:

● Pharmaceutical

● Chemical

● Utilities

● Food and Beverage

● Oil and Gas

● Textiles

● Pulp and Paper

● Agriculture

Investments

The global Industrial Wastewater Treatment Market is expected to exceed $16.5 billion by 2027 and the market is anticipated to display a compound annual growth rate (CAGR) of 4.5% from 2020 through 2027 (report by Acumen Research and Consulting).

Statistics provided by the United Nations show that over 1.8 billion people around the world are drinking contaminated water.

The United Nations have created 17 Sustainable Development Goals (SDGs) to help create a better and more sustainable future for everyone. SDG 6 focuses on Clean water and Sanitation. Water scarcity affects over 40% of the global population, and this number is expected to rise over the coming years. Shockingly, more than 80% of wastewater created by human activities is discharged into rivers or seas without appropriate pollution removal.

Market potential for Membrane Distillation

The above figure shows the market potential estimate for the market segment “Industrial wastewater”.9 The green tech segment has a growth forecast of 7% and continues to rise steadily (source: Roland Berger Institute 2018)

In 2016, the global market volume for environmental technology and resource efficiency exceeded the three trillion-euro mark in 2016, amounting to 3,214 billion euros whereas 667 billion euros accrue for sustainable water management and 521 billion euros in raw material and material efficiency – the two core activities of SolarSpring.

Trends and challenges

The global shortage of water makes water as a raw material one of the most precious goods in the world. The uninterrupted supply of clean water for drinking, agriculture and industry is one of the great challenges of the future.

European plant engineering (with a highwater consumption in the manufacturing process) is coming under increasing pressure from new requirements on the part of customers, the digital transformation and competition, especially from China.

The “megatrends” in the field of environmental technologies/energy/Clean Tech are often described in six fields: 1) energy efficiency, 2) digitalization, 3) sector coupling, 4) decarbonization, 5) renewable energies and 6) circular economy.

The simplicity of MD along with the fact that it can use waste heat and/or alternative energy sources, such as solar and geothermal energy, enable MD to be combined with other processes in integrated systems, making it a promising separation technique.

It is estimated that between 20 to 50% of industrial energy input is lost as waste heat in the form of hot exhaust gases, cooling water, and heat lost from hot equipment surfaces and heated products. As the industrial sector continues efforts to improve its energy efficiency and as MD water treatment processes can be driven by waste heat MD water treatment is especially promising.

Waste, heat potential per industrial sector in the EU (%), Preliminary assessment of waste heat potential in major European industries

E.E: What are the most innovative products marketed?

SolarSpring: Definitely the membrane distillation systems.

E.E: What estimations do you have for 2021?

SolarSpring: Well, the year is nearly over but we expect to see some more sales of the drinking water systems and the deployment of pilot systems in the industry for industrial wastewater treatment.