For more than 35 years, SSV Software Systems (SSV) has been developing, producing and marketing microcomputer modules (embedded systems), assemblies and systems that are used with special software in the field of industrial and process automation for demanding communication tasks.

From Hanover, Germany, the company serves a worldwide customer base in various market segments. Their goal is to make machines and processes considerably more intelligent. The SSV team consists of highly qualified engineers, technicians and business people, enabling them to solve very complex tasks in the field of industrial communication technology individually, effectively and efficiently.

SSV offers a variety of products, ranging from simple sensor data field bus couplers, to wireless sensor networks and 4G-based cloud gateways for the Internet of Things, to complete cyber-physical systems. They have field-tested and perfected solution modules as well as a development process to develop an optimal solution with high user benefits and a competitive price/performance ratio to match customer requirements.

Easy Engineering: What are the main areas of activity of the company?

SSV: With the help of SSV, machine and system builders can integrate their products into communication networks like the Internet in a secure and intelligent way. This enables high-quality remote maintenance and monitoring applications to be implemented in order to avoid unplanned machine downtimes and to guarantee trouble-free machine operation at all times as well. In addition, the network integration creates additional data interfaces (e.g. OPC UA), which can be used to optimize machine operation using optional software functions. SSV supplies all the hardware and software modules needed, plus the necessary cybersecurity functions for such integration applications. Furthermore, SSV also has numerous highly developed networking solution building blocks to offer for machine operators for data-centric applications. They are primarily used to obtain real-time machine data for the MES and ERP IT applications in a production environment. This enables the creation of various KPIs, such as to determine the overall equipment effectiveness (OEE).

E.E: What’s the news for 2021 about new products?

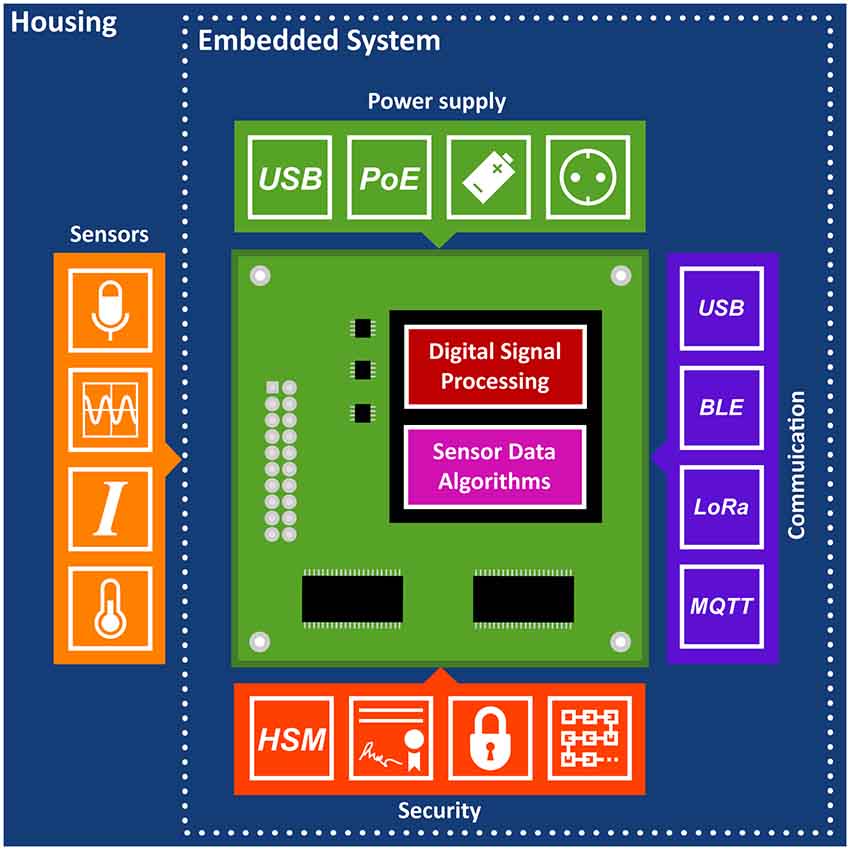

SSV: The main focus for the SSV product development is currently on production machines as a high-quality data source for IT software applications such as CRM, ERP, SCM, PLM and MES. With our new product developments – the technology stack ‘WSEI/154A’ for wireless sensor applications with various wireless technologies and TensorFlow-based AI components, as well as our ‘SFS Family’, a modular Smart Factory sensor kit system – we are focused on the task of providing IT applications with high-quality real-time data from machines and processes. We already have found first customers for both products in order to implement pilot projects. By entering the market with a new product and conducting intensive discussions with customers, we always come up with a lot of new ideas in regard to additional product features. We are constantly evaluating these ideas in order to then implement them with additional software functions and new supervised machine learning models for our TensorFlow runtime environment.

E.E: What are the ranges of products?

SSV: The SSV products can be divided into two groups:

- Connectivity solutions with gateways and special software functions;

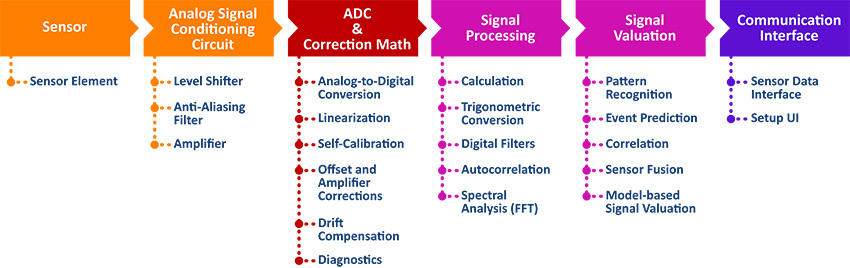

- Data-based solutions with the help of sensors and data analysis algorithms.

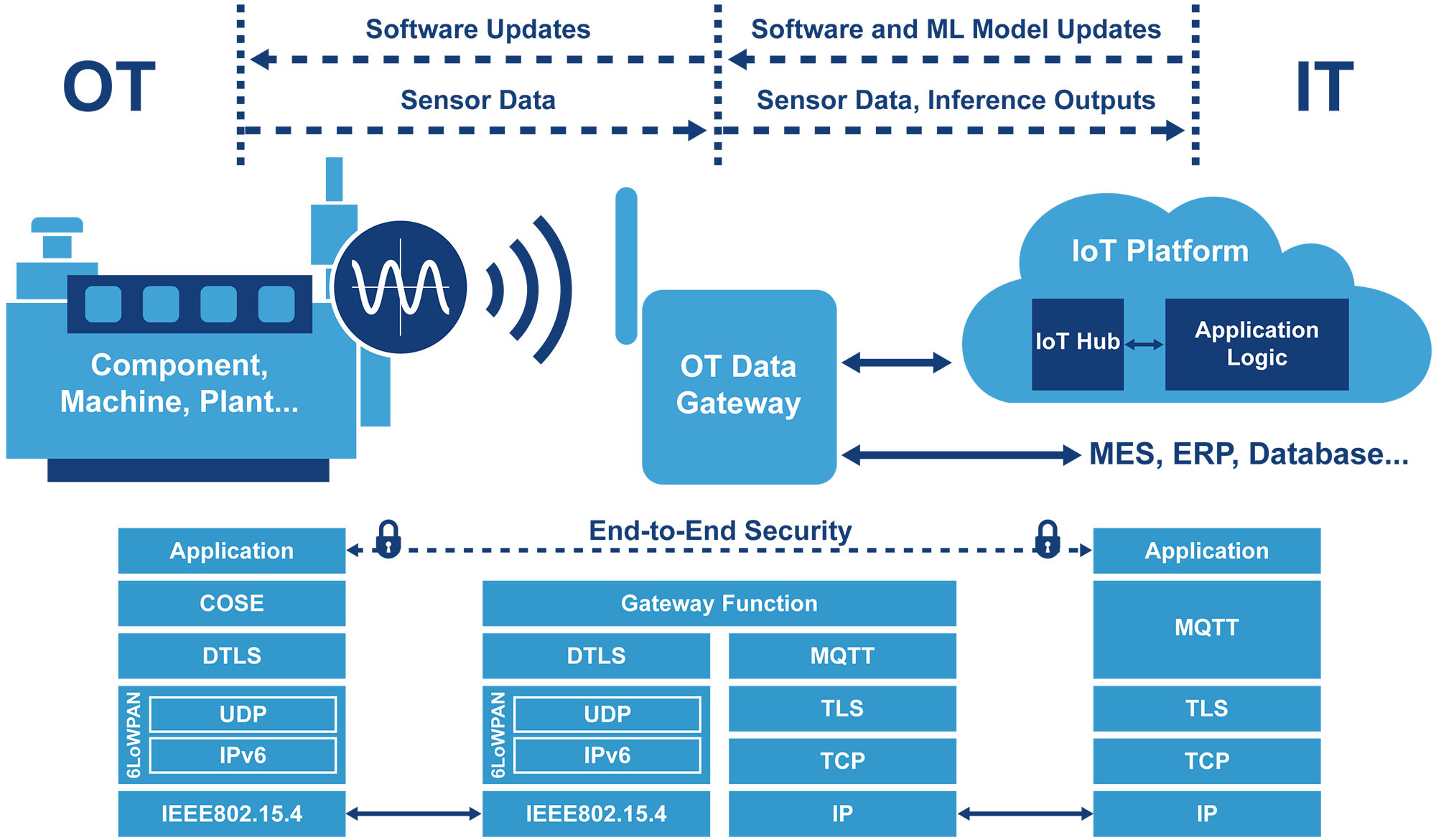

Connectivity is primarily about connecting components, systems and machines with communication networks (local or global, e. g. to public clouds). On one side, SSV gateways need numerous different machine interfaces, such as CAN buses, Modbus TCP, Modbus RTU or Profinet. The other side – the connection to a network such as the Internet – requires Ethernet, Wi-Fi, 4G and protocols like HTTP, MQTT and OPC UA together with the necessary cybersecurity components. The SSV data-based products include special machine sensors with embedded IoT operating systems as well as wired and wireless data interfaces. In addition, there are highly developed software functions from the field of artificial intelligence for regression and classification tasks using supervised machine learning.

E.E: At what stage is the market where you are currently active?

SSV: Everything that has to do with connectivity in the area of machines and production environments can be regarded as very highly developed. Especially in the area of simple communication interfaces, like the ones based on Ethernet technology for example, there are countless product and solution providers. It looks similar with cloud connections. If you want to connect a production machine to the Amazon or Microsoft cloud, the market offers you many alternatives. The situation is completely different with AI-based products for machines and systems, i.e. data-centered problem solutions. The market is currently developing here. SSV is active in both market segments. The focus is now more in the area of data and algorithms for machine data usage.

E.E: What can you tell us about market trends?

SSV: In our target markets you can see the trend towards equipping new production machines ex works with an OPC UA communication and data interface. In the past, most machines were totally closed in terms of connectivity. At best, there was a service communication interface in the PLC through which an authorized technician could access internal data variables or uploads new PLC software versions. Retrofitting of connectivity was necessary in order to transfer internal machine data to an external IT application. That is now changing due to the OPC UA trend. Another trend is to process machine and sensor data directly at the OT level right on the edge. So far, some of this data has even been transferred to a cloud in order to use the IT services available there for data processing. Edge computing is now spreading with sophisticated edge devices very close to the machines and sensors. New software applications can even be used as Docker containers on these edge devices.

E.E: What are the most innovative products marketed?

SSV: From my point of view the highest degree of innovation comes with factory automation products based on embedded systems solutions that use Google’s open source library TensorFlow to implement sophisticated embedded AI functions at the edge. I don’t mean the numerous single-board computers with high-end processors; thick heat sinks or even fans to run a full-function TensorFlow implementation like in a cloud. That would not really be an “embedded AI” either. I mean tiny microcontroller-based systems that use TensorFlow models for an inference machine. These are real innovations. This means that the AI can move into all areas of factory automation, even directly into sensors. This kind of solutions can be used, for example, to automate maintenance tasks: a machine can independently determine when maintenance is required, which work has to be carried out and which spare parts are needed. The energy requirement for machine operation could also be automatically optimized with such embedded AI functions.

E.E: What estimations do you have for 2021?

SSV: First of all, I wish that humanity will be able to defeat COVID-19 in the course of the year and that the numerous restrictions to our everyday life will gradually disappear. I hope that face-to-face fairs will take place again towards the end of this year. I am already looking forward to face-to-face discussions with customers and other experts from our industry. In addition, I assume that the acceptance of the use of artificial intelligence in factory automation will increase significantly. This not only requires more specialized knowledge of the algorithms and their application from everyone involved. The dissemination of a generally recognized set of rules, such as the EU document “Ethics guidelines for trustworthy AI”, would also be an important aid to orientate oneself. The use of AI in embedded systems and factory automation applications has considerable potential, especially in interaction with edge assemblies. However, there are also numerous new challenges and problems for which everyone has to find solutions together.