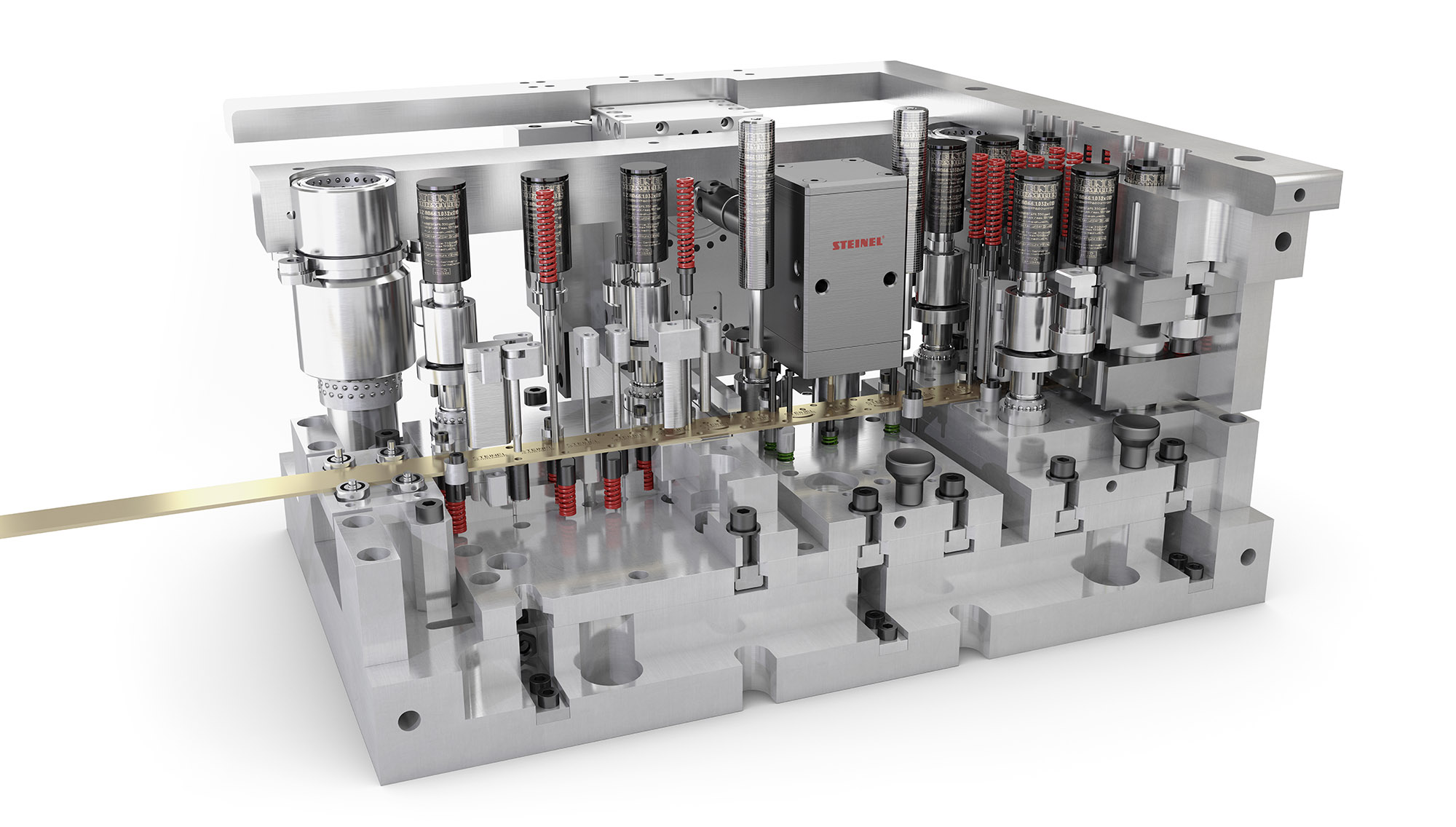

STEINEL is a 100-year-old family-owned company which specializes in tooling.

The range of services is impressive: from the production of all standard parts, active elements and tool systems to the implementation of complete solutions. With around 130 employees, STEINEL manufactures at two production facilities in Villingen-Schwenningen and Buching im Allgäu in Germany. The company is now a well-known brand in the punching and bending industry and a solutions provider for the machine building sector.

Interview with Uwe Strohm, Sales Export at STEINEL.

Easy Engineering: What are the main areas of activity of the company?

Uwe Strohm: We are a standard parts supplier as well as a system solutions partner. We have expanded our product range in discussions with our customers and proved to be a reliable partner and supplier.

E.E: What’s the news for 2021 about new products?

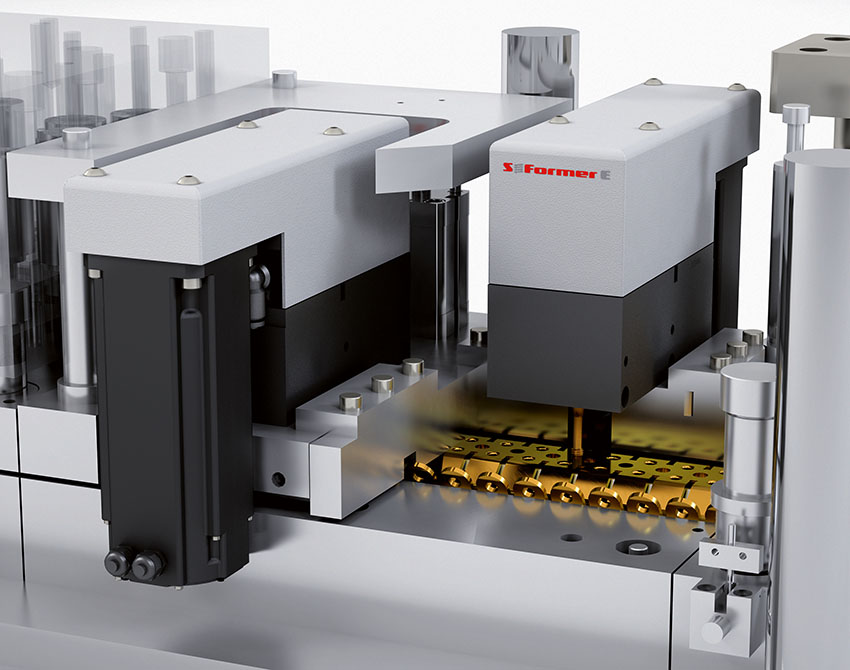

U.S: This year, we have a new software update for the control of our tapping unit S-Former E. We have also developed a new high-speed clamping system that allows to replace roll taps easily without any tools. In general, we always strive to introduce innovation and work on further improvements for our existing products.

E.E: What are the ranges of products?

U.S: At STEINEL, we offer the complete range of tooling products necessary for toolmakers in stamping and pressing industry – basically everything you need from guiding units up to high-end tooling for high-speed presses. Also, we offer punching and bending tools, tapping units, nitrogen cylinders, manifold plates and die sets.

E.E: At what stage is the market where you are currently active?

U.S: The past year has been difficult due to the pandemics, but after this critical period our main markets are now coming back to business. So we are all looking forward to positive developments in automotive industry, electronic industry as well as packaging industry and mechanical engineering.

E.E: What can you tell us about market trends?

U.S: There is a number of trends in global tooling markets. A key trend is advancing standardization and digitalization in tooling systems. Because of the unavoidable development of predictive maintenance, we expect to see more intelligent systems in the future. We have already developed our modular tool system and the electronic tapping unit (S-Former E), in line with this trend.

We assume that the globalization and internationalization of the industry will lead to stronger price competition for products of comparable quality. Yet still, special solutions will always be important when it comes to generating a real competitive advantage. For us as a manufacturer of high-quality and high-precision products, this will be an opportunity. On the one hand, we offer our customers intelligent and reliable systems that significantly increase production efficiency. On the other hand, we develop individual solutions that are tailored to our customers’ production processes. I am sure that in the future we will be able to offer our products in new markets in which we are not yet present.

Our focus over the next few years will be to increase activities in new markets such as electromobility and renewable energy as well as to further develop STEINEL’s products in order to support our customers in the digitalization process.

E.E: What are the most innovative products marketed?

U.S: There is a number of such products in our portfolio! Beginning with the nitrogen systems and manifold plates through to tapping units, different guide elements for special applications or new materials for standard guide elements.

E.E: What estimations do you have for 2021?

U.S: In 2021/2022, we expect the economy to stabilize and look forward to new developments in our main industries.