Bavaria is one of the leading locations in the sensor technology sector worldwide. The regional network Strategische Partnerschaft Sensorik e.V. (SPS)/Cluster Sensorik has been pooling Bavaria’s sensor expertise of companies, universities and research institutes on behalf of the federal state of Bavaria for 15 years. “Intelligent sensor systems made in Bavaria” is the strategy of the around 85 members and over 250 partners. High-tech expertise meets network know-how: In the Regensburg office, an experienced, interdisciplinary network team and the technology experts of the wholly owned subsidiary Sensorik-Bayern GmbH work together. This enables players not only to network, but also to drive developments in the fields of industrial internet of things (IIoT), big data, blockchain, and even bionics – an innovation center the entire network benefits from.

Easy Engineering: What are the main areas of activity of the company?

SPS: The Strategische Partnerschaft Sensorik e.V. (SPS) offers actors in the Bavarian sensor industry from business and science a wide range of services. Depending on their individual needs, members and partners can take advantage of various formats for networking or consulting and support in the area of organizational and personnel development. Marketing for the sector, but also for the individual company and active participation in shaping technology development are further components of the SPS’s service portfolio. This is enabled by funding from the Cluster Initiative Bavaria of the Bavarian Ministry of Economic Affairs, contributions from network members, and funding at state, federal and EU levels.

The focus of the cooperation is the joint development of new solution approaches for future technologies under the guiding strategy “Intelligent Sensor Systems made in Bavaria”. The network management supports members in developing innovative, internationally competitive business models, products and services. Broadly based scientific studies, among other things, provide guidelines for future-proof technological road mapping. On this basis, the SPS also gives political actors recommendations for action to promote technology. We help our members with their decision making in the development of innovative, internationally competitive products and services. Interdisciplinary and cross sectoral networking approaches that are indispensable in this context are taken into account.

Our main focus:

- Intelligent sensor and measurement technology;

- Digitalization and digital transformation;

- Safety and security;

- Automotive, automation;

- Electronic systems.

E.E: What’s the news for 2021 about new products?

SPS: In a joint project with the New Materials cluster, we are focusing on bioeconomic aspects: We are pooling our expertise to realize a new generation of printed circuit boards. Bio-based, renewable substitutes for synthetic resins or polymers or natural fibers are to take the place of non-recyclable materials in the future. The cross-cluster project is in line with the Bavarian bioeconomy strategy: with sustainable innovations, the path to a transformation of the Bavarian economy and society towards more climate neutrality should succeed across all sectors. In order to initiate projects in the bioeconomy and to network actors across industries and sectors in a targeted manner, the established cluster structures are helpful.

Artificial Intelligence (AI) is another important topic on our agenda. In the AIR (Artificial Intelligence Regensburg) initiative we are working with four other clusters to deliver a future-oriented regional development concept for “our” region (Regensburg, Bavaria) that actively involves and mobilizes their respective stakeholders. Right now, we start to develop a new cluster service: the new “Data-driven Business” service unit is intended to help not only generate data, but also use data and manage data flows efficiently. Only when data becomes information can new value be created.

Furthermore, our Cluster Sensorik was one of the 25 selected clusters in the ‘Towards Green Transition’ Facility. In this Facility, selected clusters are trained and advised on a range of green transition topics so they can support their cluster members (especially SMEs) to become more resource efficient. In a series of several workshops from Jun to September 2021 we put sustainability on the cluster’s agenda. Among others, the following questions were addressed: How can sensor companies contribute to a sustainable transition and what are the opportunities to do this more in future? The series was designed to kick off the conversation among the members and aims to create the basis to establish cluster functions on sustainability.

E.E: What are the ranges of products?

SPS: Sensorik-Bayern GmbH supports us as a research partner and development service provider in the areas of Industrial IoT (IIoT), application-specific sensor systems, blockchain through to bionics. It is a 100% subsidiary of the Strategische Partnerschaft Sensorik e.V. In partnership with the 85 members of the Bavarian sensor technology network, we are shaping future technologies in cooperative projects. We have already realized and tested a high-performance IIoT measuring system for the intelligent condition monitoring of plants and machines, medical technology solutions as well as innovative sensor systems in the field of robotics and bionics. We develop customer-specific electronics and algorithms using state-of-the-art semiconductor sensors and system-on-a-chip solutions.

Some more insights:

With the help of embedding technology, our BMBF-funded project PCB 4.0 – Highly Miniaturized and Energy Self-Sufficient – Wireless Sensor Nodes for the Industry of the Future achieved a previously unattainable level of miniaturization of wireless sensor technology for Industry 4.0 applications. Intelligent control and networking can take the flexibility, energy and resource efficiency of production processes to a new level.

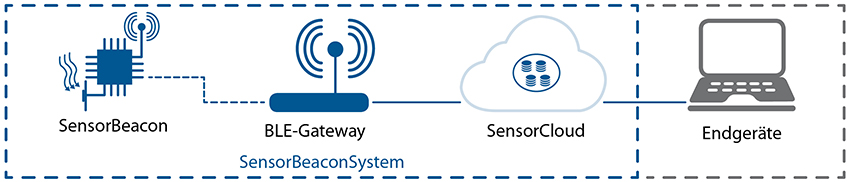

The SensorBeacon system addresses companies that want to integrate Industry 4.0 solutions into existing plants in particular and get them up and running quickly and easily. Users do not have to build up their own know-how for the integration of an IIOT solution and are supported in the development of the company towards Industry 4.0. Buzzwords in this context are RetroFit and Predictive Maintenance – both are easy to handle with the system.

The animal kingdom is also providing inspiration for new technological solutions in this area for the BMBF-funded “RoboSkin” project. With six partners we are developing a robot platform whose core element is a new type of three-dimensional flexible sensor skin, the “Bionic RoboSkin”. The model for this was the manta ray. The Bionic RoboSkin is based on a three-dimensional textile composite that serves as an integration platform for sensors or more complex sensor modules. In addition to moisture-resistant electrical connections for energy supply and communication, woven-in sensor structures are also implemented on the textile carrier. Various other sensors, as well as the central control unit of the autonomous service robot, are mounted on the textile carrier in the form of highly compact modules and electrically connected to it.