Takimsan was established in 1981 located in Istanbul/ Turkey and manufactures planetary extruders. Their planetary extruders production capacity ( 50-2000 kg/hr) for different materials such as rigid PVC, soft PVC, filled PVC, transparent PVC, PE+CaCO.

Takimsan sells their products to 5 main continents and has an international office located in Dubai/ UAE as well. Therefore they can easily serve to MENA region without any hesitation.

The company is attending all international exhibitions like K Platic&Rubber in Düsseldorf, Plast Eurasia in Istanbul from all around the world to be closed with their existing clients and meet with potential buyers.

Easy Engineering: What are the main areas of activity of the company?

TAKIMSAN: We manufacture Planetary Extruders and Spare parts of planetary extruders.

The sectors we focused on are Cable, Hoses, Films, Window Gaskets, Profiles, Tubes, Furniture Edge Tapes, Plastic Veneers.

Most of our clients are well satisfied with our granulator machinery for the above sectors.

E.E: What’s the news for 2021 about new products?

TAKIMSAN: R&D departments of companies and universities showed great interest in our laboratory machines. We had several projects during 2020-2021 from Ireland, Poland. We find an opportunity to improve our planetary extruders while supporting our clients’ researches. Our company is always open to all kind of Test and R&D works with our customers’ collaboration.

E.E: What are the ranges of products?

TAKIMSAN: The ranges are:

E.E: At what stage is the market where you are currently active?

TAKIMSAN: We are currently active in MENA Countries, GCC Countries, Europe, CIS countries as well. We have a cooperate sales office located in Dubai/United Arab Emirates which allows us to manage all these countries in one hand. We have a well-educated technician for after-sales services. We can able to serve all around the world.

E.E: What can you tell us about market trends?

TAKIMSAN: During the pandemic, plastic markets grow up to %50 because of single-use consumption increase all around the world. We always serve our clients in the pandemic situation as well. We are trying to keep marketing activities during the pandemic.

E.E: What are the most innovative products marketed?

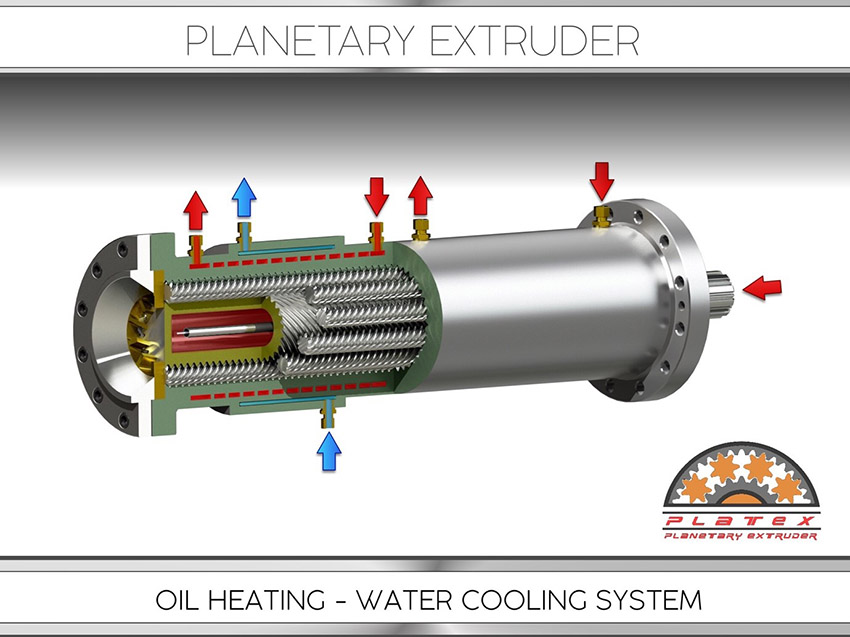

TAKIMSAN: The planetary system consists of a hollow barrel, the main spindle (screw), and several satellite spindles (screws) which work harmoniously with each other enabling the best-known mixing and plastification. The very efficient Planetary Extruders on PVC achieved great success in the pellets (granulated raw material) production. The biggest advantage of the Planetary Extruders is to ensure excellent plastification and homogeneous mixing of raw materials thereby eliminating all the eventual problems i.e. degassing during further processing and extrusions. We complete the entire mechanical parts production and electronic assembly of the extruders at our factory where we also manufacture complete planetary gearboxes. The planetary gearboxes produced by our company assure substantial electric power savings and a higher power transfer ratio compared to other traditional gearbox designs

E.E: What estimations do you have for 2021?

TAKIMSAN: We will attend The Compounding World will take place on 29th -30th September 2021 in Germany.

Also, Interplas, the UK’s most important plastics event, will attend and opened its doors on 28–30 September 2021. We believe we will have an efficient year in 2021.