TAV VACUUM FURNACES is an Italian company founded in 1984 by Mr Tonini and a group of entrepreneurs active in the field of heat treatments. The strong entrepreneurial spirit, engineering skills and hard work has led TAV VACUUM FURNACES to be one of the players in the production of high-quality vacuum furnaces with an established presence in European market and in the past decades they were grown their presence in Chinese, North American and Asia pacific market.

Through their large team of experienced mechanical and automation engineers, supported by the most advanced software and instrumentation, the company provides timely and qualified solutions to customers.

Interview with Guido Locatelli, General Manager at TAV VACUUM FURNACES.

Easy Engineering: What’s the news about new products?

Guido Locatelli: We have heavily invested in our R&D department in the last two years. Through collaboration with Universities and Research Centers our R&D department is implementing and validating new processes and technologies that will be implemented in our products.

The department is focused in following and supporting our customers from the beginning. Customers can benefit of a closed and strong collaboration: heat treatment of sample, metallurgical analyses and hardness test can be performed in our R&D department to help our customer in proof, fine tuned and validate their processes.

Low pressure carburizing and nitriding are two of the projects we are working on currently and we’ll soon be ready to offer in the market.

E.E: What are the main areas of activity of the company? What are the ranges of products?

G.L: Throughout the years, we have developed a deep understanding of customer’s needs and how to best cater to them with quality service.

Our vacuum furnaces are used in wide range of heat treatments for different materials such as steels, alloys, superalloys, advanced ceramic, for hardening, solubilization, annealing, brazing and sintering.

They are mainly applied in the following sectors: production of heat exchangers, aviation/aerospace, automotive, IGT (industrial gas turbine), additive manufacturing, commercial heat treatment, component sintering industry (medical, precision mechanics, optics, fashion).

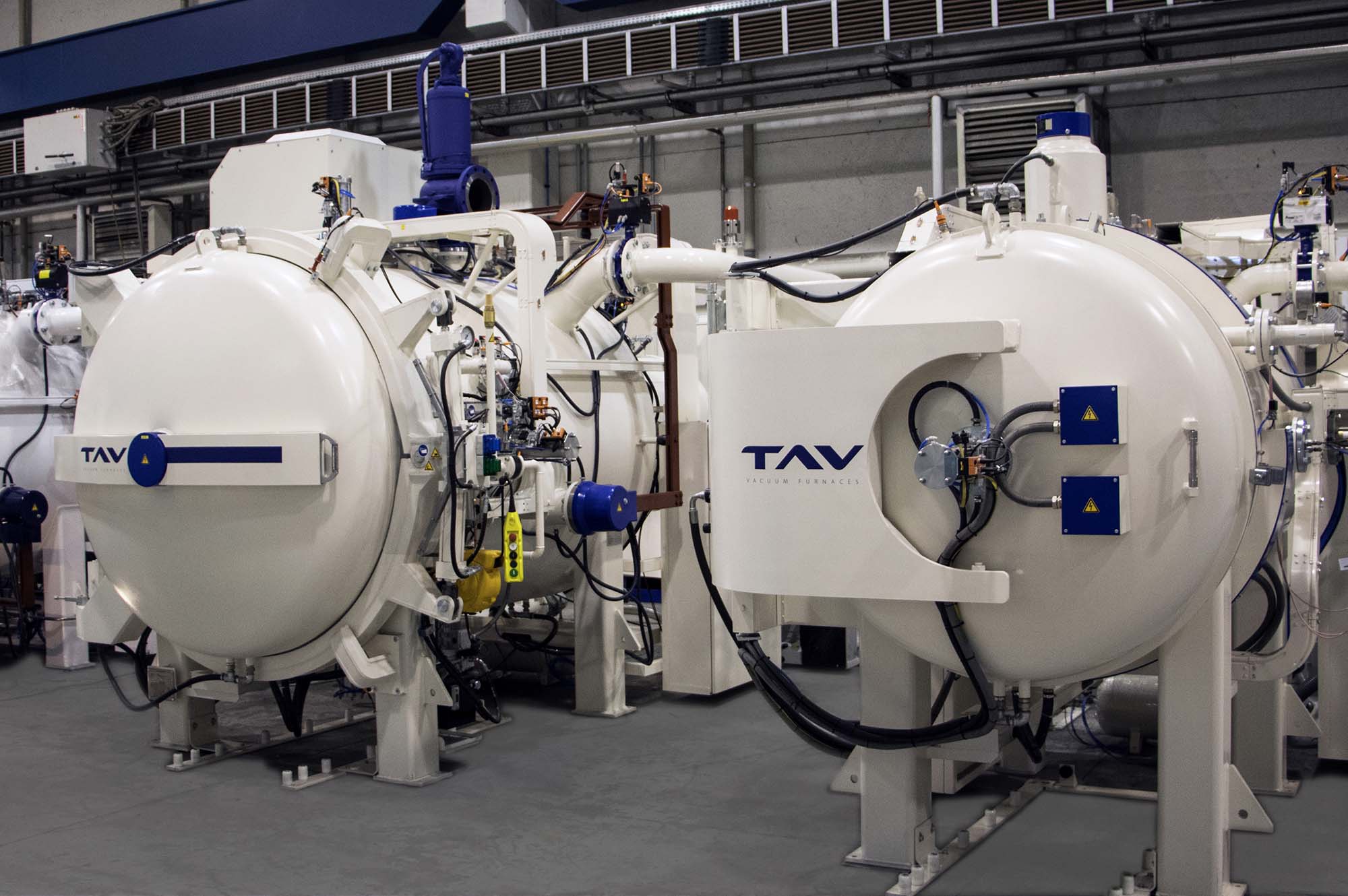

TAV VACUUM FURNACES designs and manufactures vacuum furnaces with different configurations, range of temperature and working pressure.

Horizontal vacuum furnaces with a hinged door, horizontal vacuum furnaces with a cart bottom door, and vertical vacuum furnaces with a top or bottom load are all part of our portfolio.

Our furnace could work in a very wide range of temperature up to 2,800°C and with pressure from Ultra High Vacuum, used in nuclear and research laboratories, till 150 bar for hot isostatic pressure application.

All our product could be highly customized to meet customer needs and achieve the best integration in their production plants and processes.

Our quality department supervises all activities from the acquisition of materials to the fine-tuning of our products with a view to a global quality concept. It supervises all commissioning and testing at customer premises in order to guarantee the best results and performances

Service and after sales job are performed through a network of companies: FURNACARE Inc. for North American market and TAVENGINEERING for the rest of the world.

E.E: At what stage is the market where you are currently active?

G.L: Vacuum heat treatment market is transversal to different industry like aviation, automotive, medical, defence, etc…

Since the beginning of 2020 the market has shown signs of recovery, although there are still major uncertainties linked to the global situation. The greatest uncertainties are due to the lack of recovery of the aviation and automotive sectors, historically driving our industry.

We’ll expect during 2022 to return at the same position before the pandemic.

E.E: What can you tell us about market trends?

G.L: As the heat-treat industry has evolved, TAV VACUUM FURNACES has continued to evolve with it.

There are some new processes that are coming with additive manufacturing, like binder jetting, that will for sure grow the market in the future. There will be a lot of requests and demand for furnaces for that kind of process. Most of the part obtained with AM process needs to be heat treated, especially with binder jetting. This technology will move the AM parts to large volume production, whereas laser sintering now is focused on smaller volumes.

Vacuum furnaces are the safer and environmentally friendly heat treatment process, this market will grow in the future.

The increased attention to environmental and safety issues will lead to a greater demand for vacuum furnaces in the future. Producers of vacuum furnaces are constantly looking for better performance of their products to replace the use of traditional heat treatments such as quenching in oil or salt baths.

Using environmentally sustainable equipment is an important mission for TAV in that many industries, including automotive, are looking to manufacture parts without any potentially hazardous implications.

Vacuum heat treatment process is surely a sustainable technology and TAV is working to develop high performance furnace to replace traditional heat treatment.

E.E: What are the most innovative products marketed?

G.L: TAV VACUUM FURNACES has a strong position in aviation industry where stringent needs and rigid regulation push the performance of the furnace at the highest point for temperature uniformity and vacuum range.

Our vertical bottom loading vacuum furnaces are expressly designed for this market and today we are manufacturing one of the largest furnaces in the market.

E.E: What estimations do you have for 2022?

G.L: There are signs of market recovery and a big push toward restoring normalcy, so we expect to return at the same level of 2019.