Tecnomacchine is the leading manufacturer and supplier for gear deburring machinery and industrial automation systems based in San Salvo, Italy. Their motto is “We design the solution around the problem”, consequently the focus is shifted from the machine to the customer’s actual needs.

Whether it be customers in the automotive, agricultural, aviation or wind energy sector, their product portfolio satisfies the most complex requirements. With over 20 years of experience on the market and more than 200 delivered machines all over Europe, USA, Asia and Africa, Tecnomacchine’s customers consider them as a long-term partner for raising their operating efficiency.

Interview with Jessica Iacovitti, Interntational Sales at Tecnomacchine.

Easy Engineering: What are the main areas of activity of the company?

Jessica Iacovitti: Tecnomacchine operates in two main areas:

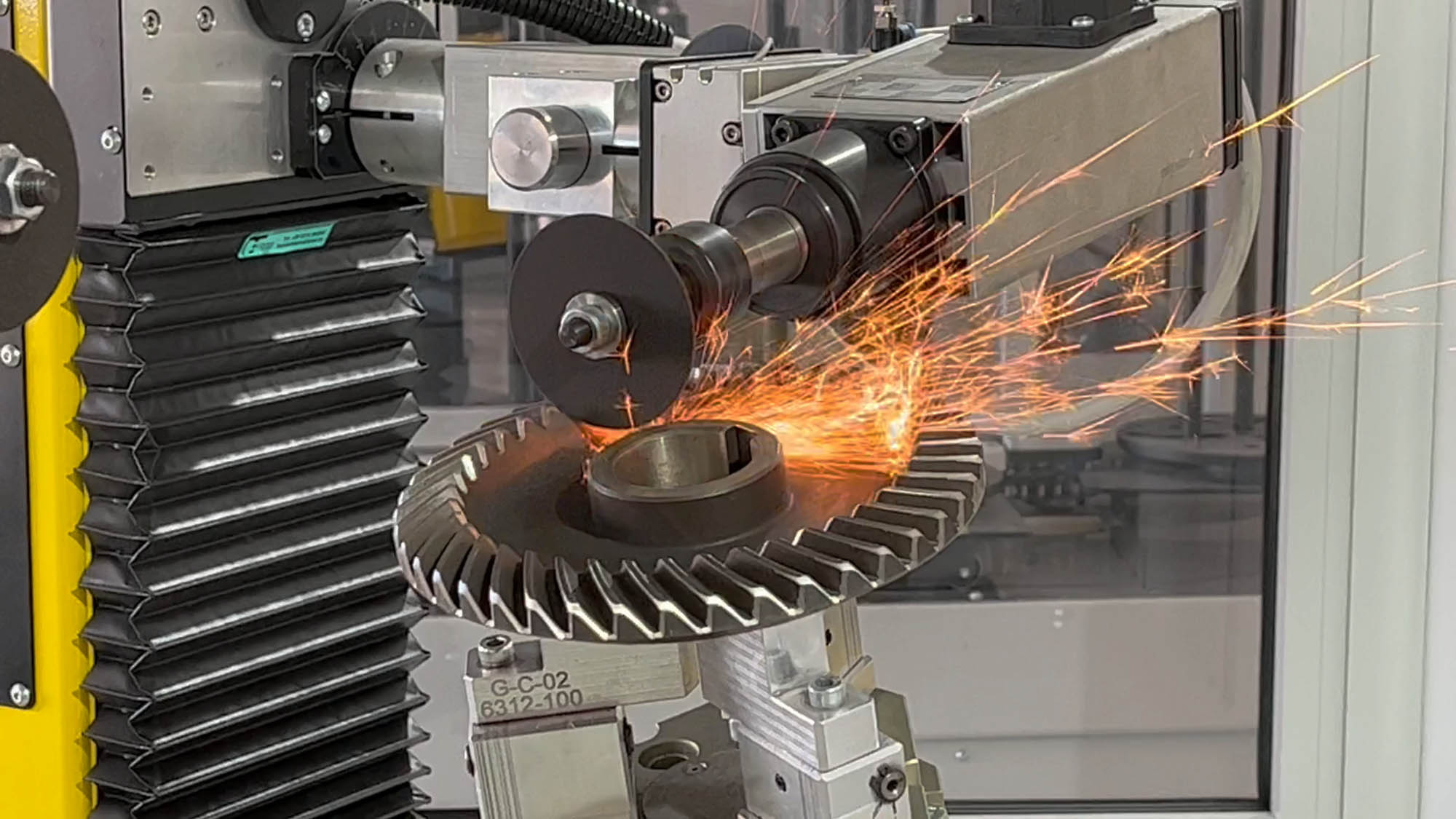

On the one hand, in the gear production sector. The company started as a supplier for gear chamfering machinery, which is to this day our core business. We provide turnkey solutions ranging from small to very large parts, from stand-alone machines to complete manufacturing lines. Our machine models with multiple stations ensure extremely short cycle times. Based on the size and geometry of the workparts, we offer a variety of options with regards to deburring and brushing tools in order to gain the maximum versatility. In fact, one of the additional services that we provide is consultancy with regard to tooling. Thanks to our long-lasting partnership with various tool manufacturers, we are able to support the customer in finding the most cost-effective tools – whether it be milling tools, ceramic and CBN cut-off wheels or brushes.

The second area of activity is the automation sector. One of Tecnomacchine’s distinctive features is that we provide machinery with integrated automation, thus ensuring high autonomy on very reduced space. Our solutions range from rotary magazines over conveyor belts to transport basket handling systems. Our portfolio of workpart handling systems includes both gantry loaders, completely designed and manufactured by Tecnomacchine, as well as anthropomorph or collaborative robots.

Quick-change systems for the gripper jaws round off our portfolio and ensure a production changeover in just a little more than 1 minute.

E.E: What are the ranges of products?

J.I: We are known for our flexibility and customization of the machines to the customer’s exact requirements so, through the years, we have matured a vast variety of solutions.

Our deburring equipment is capable of processing all kinds of toothed parts such as spur and bevel gears, sprockets, shafts and pinions. The work part size ranges from Ø30mm up to Ø1.000mm and more.

Each solution is available with manual adjustment of the tools or as CNC-controlled version, the latter making it possible to save and re-call programs in order to reduce the changeover time and making the use of the machines accessible also to unskilled operators.

E.E: At what stage is the market where you are currently active?

J.I: While other manufacturing processes, such as turning, milling, hobbing or grinding, become automated, deburring often remains an operation by hand. This represents a challenge for gear manufacturers as labor costs continue to grow as a portion of a finished part’s overall cost and because each operator’s skill impacts the final result of the product.

E.E: What can you tell us about market trends?

J.I: Industry 4.0 and the interconnection of machines and data has been an increased interest to our customers. In response to this demand, we have developed interfaces which bring the machines and automation into communication and transfer the production data from the factory floor to the cloud.

While many customers with high-series-production have already approached and implemented the Industry 4.0 requirements in the past years, this trend is now also extending to our customers with low and medium-sized production.

E.E: What’s the news about new products? What are the most innovative products marketed?

J.I: The patented rotary magazine MSR-15 can feed up to four machines at a time, whether it be lathes, machining centers, hobbing, broaching, deburring, grinding machines or others. For the first time, we are addressing customers outside the gear production sector extending our audience to other industries, who can benefit from a setup-free and affordable automation.

Thanks to the prismatic shape of the magazine stations and their angle of inclination, the solution can accommodate both cylindrical and cuboid-shaped stackable parts with diameters, or in case of cuboid parts length/width, up to 220mm. According to the geometry of the workpart, the pick and place system can be equipped with two-jaw or three-jaw-grippers.

The magazine comes in two versions depending on the machine tool it needs to feed and on the customer’s preferences:

In one version, workpart handling is performed by means of a gantry loader entirely designed and manufactured by Tecnomacchine. This solution is particularly suitable to feed machine tools with vertical chucks. The operator interface entirely designed by Tecnomacchine, this automation allows set-up in only few operations and does not require the operator to have any prior knowledge in programming.

In the second version, workpart handling is performed by means of an anthropomorph robot programmed by Tecnomacchine. The inclination of the magazine stations towards the center optimize the solution ergonomically. This version requires slightly more space but ensures a higher range of motion and can feed machine tools with horizontal chucks such as lathes or machining centers.

The unique features of the MSR-15 are that it does not require any mechanical adjustment during changeover and its high autonomy. The fifteen stations are able to overall accommodate a stack of over 6 meters of product, so that the automation can work unattended for hours or complete shifts.

E.E: What estimations do you have for 2022?

J.I: In general, Tecnomacchine expects a growth especially with regards to the automation sector. The trend seems to be that job shops with low production volumes as well as manufacturing departments with a large variety of parts are automating their production in order to stay competitive on the market and adapt to the industry 4.0 requirements. Labor is being reduced to only where strictly necessary and the operators’ tasks are changing to controlling the result of the machining process and monitoring the machine data rather than manually adjusting tools, so we expect a continuous increase in request for solutions with streamlined set-up and changeover operations.

For the very near future, we are looking forward to exhibiting at the AMB in Stuttgart from 13th to 17th September, where we will present our two versions of the Rotary Magazine MSR-15 for the first time. The show being held in one of our reference markets and Stuttgart being in the heart of Europe and the metal working industry, we are expecting a large response and will seize the opportunity also to extend our distribution network.

Tecnomacchine S.r.l.

Via Colle Martino, 8

Zona Industriale

66050 San Salvo (Chieti), Italy

T: +39 0873-346324

Email: info@tecnomacchine.it

Web: www.tecnomacchine.it