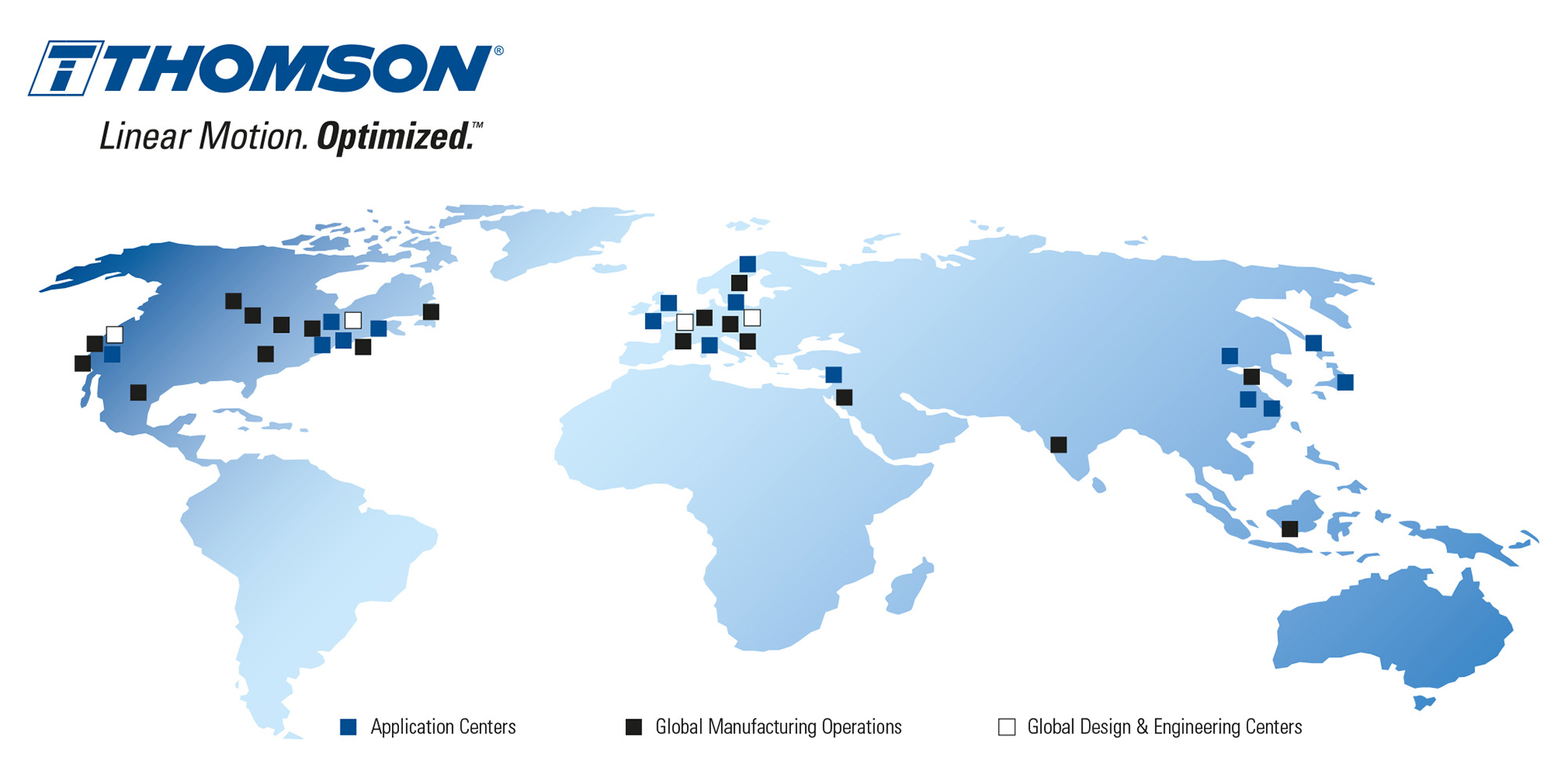

With more than 70 years of motion control innovation and quality, Thomson Industries is the industry’s premier producer of Linear Ball Bushing® Bearings and Profile Rail Bearings, 60 Case® Linear Shafting, Ball Screws, Lead Screws, Screw Jacks, Linear Actuators, Linear Systems, and related accessories. Thomson Industries, Inc. has been part of Altra Motion since 2018. The company invented the Linear Ball Bushing Bearing in 1945 and have set the standard ever since with an unsurpassed set of linear motion control solutions serving global commercial and aerospace and defence markets. They have facilities in North America, Europe and Asia with more than 2000 distributor locations around the world.

Easy Engineering: What are the main areas of activity of the company?

Thomson Industries: The Thomson brand is recognized and trusted as the global leader in linear motion technology. The broadest product offering and unbiased technology expertise enables Thomson to bring their customers the optimal balance of performance, life and cost. Design engineers turn most often to Thomson products to meet their motion control requirements for the following reasons:

- The industry’s broadest standard linear motion product line.

- Specialization in providing custom-engineered solutions quickly and cost effectively.

More than 70 years of global application experience in packaging, factory automation, material handling, medical, clean energy, printing, automotive, machine tool, aerospace, defence and other industries.

As part of Altra Industrial Motion, financial strength and unique capability to integrate control, drive, motor, power transmission and precision linear motion technologies.

A wide variety of online application, selection and training tools that help design engineers find the product that best fits their application needs.

E.E: What’s the news for 2021 about new products?

Thomson Industries: The potential to connect previously isolated devices is wide open. Geography is no longer a barrier to industrial automation and integration. The stage is set for production and automation engineers to define the actuator applications that will shape the next generation of industrial innovation.

Given the computational and communications capabilities of smart actuators, it is not difficult to imagine increased integration with other similarly enhanced sensors, data acquisition devices and production equipment, as well as other actuators. As such, today smart actuators are fully ready to participate in the emerging industrial internet of things (IIoT) where every device not only has intelligence and networking capability but also an internet address and the ability to share and subscribe to information sources. And the IIoT is part of an even broader industrial revolution, in which computational, communications and physical domains increasingly interact without human command. Known as cyber-physical systems or, sometimes, just Industry 4.0, this promises new levels of efficiency, economy and safety.

Besides that, electric and electro-hydraulic actuators are increasingly replacing hydraulic actuators due to:

- Improved power density in a compact envelope.

- Better control and wider range of control options which range from simple switches to CANbus and CANopen network control.

- Better static load handling.

- Higher accuracy.

- Zero maintenance.

- Cleaner environment.

When design engineers need the right type of linear component for their machine designs, neither of them can afford the time to conduct an extensive search – especially without having the certainty that they’re choosing the exact model required. The Thomson suite of enhanced online selector tools addresses this problem, helping design engineers identify the optimal component quickly, access the right 3D model with just a click, view pricing and lead times, and easily share that information with other members of the design and procurement teams.

Selector tools are currently available for the following product categories:

- LINEAR ACTUATORS

- BALL SCREWS

- LEAD SCREWS

- PROFILE RAIL LINEAR GUIDES

- BALL BUSHING® BEARINGS

- ROUNDRAIL SHAFTING

- STEPPER MOTOR LINEAR ACTUATORS

More tools are currently in development.

E.E: What are the ranges of traded products?

Thomson Industries: Over the past several years, our family of motion products has grown significantly and now includes BSA, Neff and Tollo – all of which are now part of Thomson, expanding our product lines in the following areas:

- Linear bearings & guides;

- Ball screws and lead screws;

- Linear actuators;

- Screw jacks;

- Linear motion systems, lifting columns;

- Precision balls.

E.E: At what stage is the market where you are currently active?

Thomson Industries: We are active in many markets but what most have in common is that they are in the early stages of transition to more digital operations. They are actively exploring how they can profit from the cloud, IIoT, Industry 4.0, big data and other digital innovations that have moved from hype to reality.

E.E: What can you tell us about market trends?

Thomson Industries: Packing more power into smaller spaces is a common goal for equipment designers. In today’s industrial landscape manufacturers are always seeking to improve efficiency and productivity while reducing operating costs. Components that are powerful, compact in size, and able to deliver the same capabilities as larger and more complex products like Thomson electric actuators or Thomson’s high-load ball screws are in high demand.

E.E: What are the most innovative products marketed?

Thomson Industries: Electric linear actuators have advanced to provide the high-load, compact advantages of hydraulic actuation but without the drawbacks. Thomson’s electric actuators can handle loads of 16 kN or more without the need for messy oils and complex hoses, valves, pumps and other assemblies.

The Thomson product range of electric linear actuators and smart linear actuators with onboard electronics is well poised to continue evolving to meet the connectivity and informational transparency that tomorrow’s applications will demand.

The following are among Thomson’s most innovative motion control solutions: advantage of advanced actuator features to enable a fluid, synchronized and safe manufacturing process. These can include fork lifts, assembly/control stations and fixtures, automated guided vehicles, and components that can be easily and quickly adjusted on the fly.

Electrak HD – These smart electric actuators are highlighted by onboard electronics that can eliminate the need for standalone controls. Higher power (up to 16 kN) opens a new, wider range of hydraulic applications to electric conversion. And they meet the most extreme OEM component environmental acceptance tests, including IP69K.