The main aspect of Thought3D (T3D) is the R&D activities. By combining knowledge of 3D printing, materials and chemistry T3D develops new materials and technologies to solve problems in additive manufacturing. Its products Magigoo® and Magigoo® Pro, are all-in-one adhesives for 3D printing, designed specifically to keep 3D prints in place during the 3D printing process and allowing the easy removal when printing is complete.

Interview with Andrei-Andy Linnas, Co-Founder of Thought3D.

Easy Engineering: Which are your best-selling products / solutions?

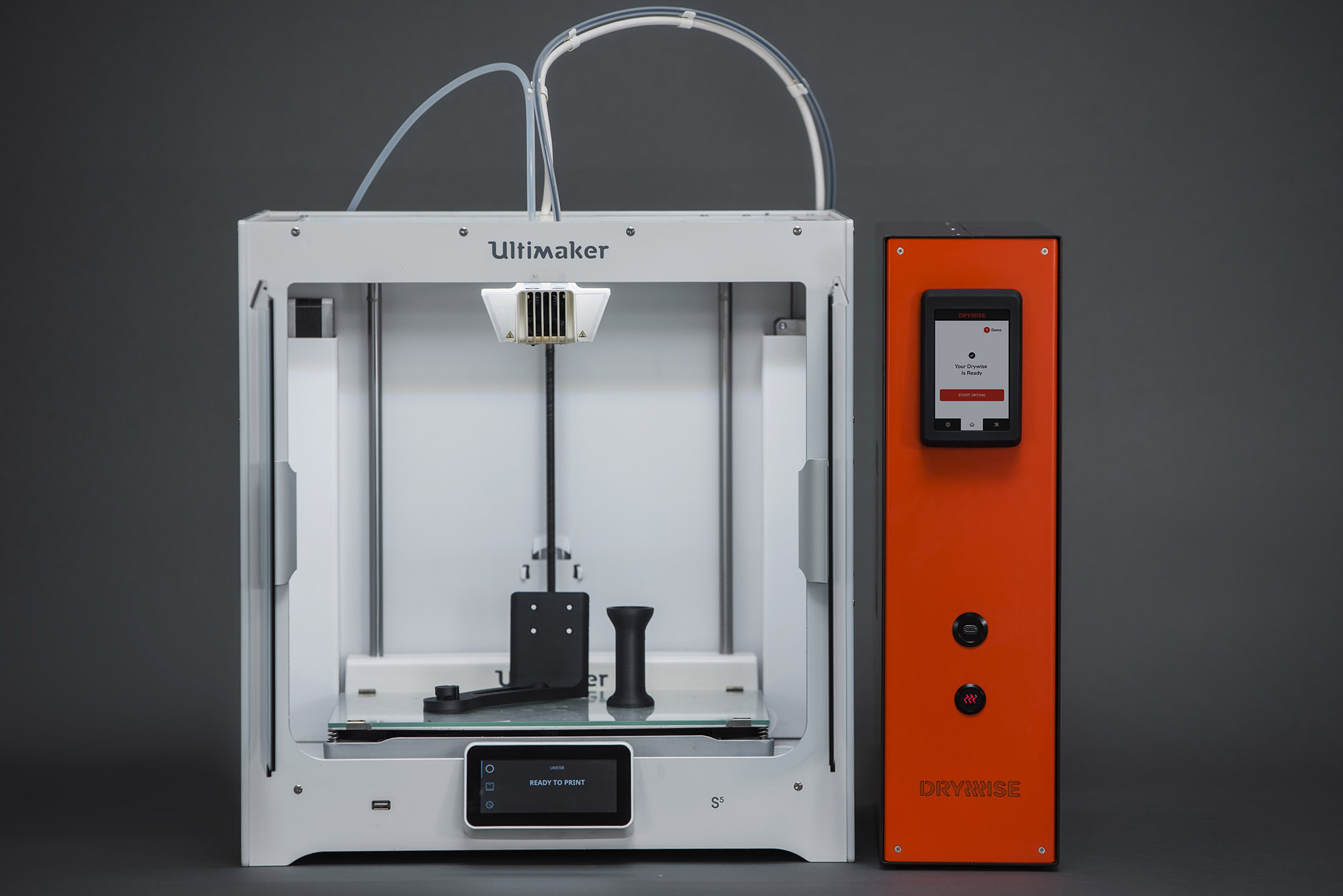

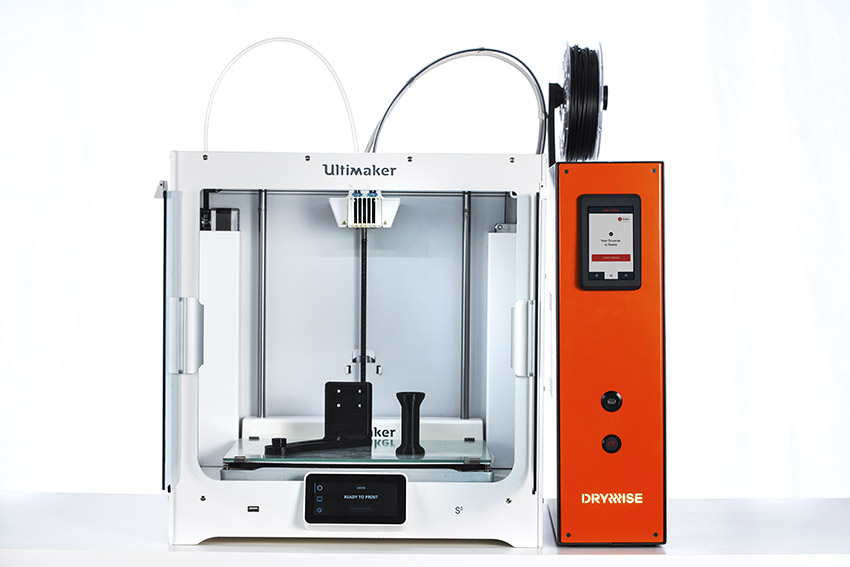

Andrei-Andy Linnas: Thought3D’s best-selling products and solutions are primarily focused around the Magigoo and Drywise brands. Magigoo is a bed adhesive solutions designed for 3D printing, ensuring that prints stick to the build plate during the printing process and easily release when cooled. Drywise, on the other hand, is an innovative inline filament dryer that pre-processes 3D printing materials by removing excessive moisture, enhancing print reliability and serving as a quality assurance tool.

E.E: Why do users choose your products / solutions?

A.A.L: Users choose Thought3D’s products and solutions for several reasons. Magigoo adhesives are designed to be easy to use, reliable, and compatible with a wide range of materials, ensuring successful prints and minimizing failed prints. Drywise filament dryers enhance the print quality by providing consistent material properties throughout the printing process, leading to better results and fewer issues related to moisture.

E.E: What special features do your products / solutions have?

A.A.L: Thought3D’s products boast several special features:

Magigoo adhesives are formulated for specific 3D printing materials, including PLA, ABS, PETG and engineering materials, including PC, Nylon, PP, PPGF, Metal and High temperature materials. The tailored formulations help ensure optimal adhesion and release properties for each material type.

Magigoo products are non-toxic and environmentally friendly, making them suitable for use in various settings, from professional workshops to educational environments.

Drywise storage solutions employ cutting-edge technology to maintain optimal humidity levels, using smart sensors and automatic moisture control systems to preserve the quality of 3D printing filaments.

E.E: Tell us a short tutorial of how a task is done more efficiently with one of your products /solutions.

A.A.L: A short tutorial on using Magigoo for better 3D printing results:

- Clean the print bed to remove any dust or debris.

- Shake the Magigoo pen well and apply a thin, even layer to the print bed where the object will be printed.

- Once the print is complete and the bed has cooled, the object should easily release from the surface.

A short tutorial on using Drywise for better 3D printing results:

- Insert 1.2 meters of material into Drywise and select right filament drying profile

- Wait between 30-50 minutes to dry the first segment of the filament

- Load the dried segment to the 3D printed and start printing.

The 3D printer will keep pulling new segments through Drywise, drying them in time, achieving the consistent print quality though every 3D printed layer.

E.E: How did your products / solutions improve efficiency for the users overall?

A.A.L: Thought3D’s products improve efficiency for users overall by reducing the number of failed prints, minimizing material waste, and preserving the quality of materials. This leads to faster turnaround times, better print quality, and a more enjoyable 3D printing experience.

E.E: Give us some examples of projects in which your products / solutions were used?

A.A.L: Examples of projects where Thought3D’s products have been used include:

- Rapid prototyping for product development in various industries, such as automotive, aerospace, and consumer electronics.

- Educational institutions incorporating 3D printing into their curriculums for hands-on learning experiences.

- Makerspaces and hobbyists creating unique, custom-designed objects for personal use or small-scale production.

Specific examples:

Magigoo Metal used by BASF, Ultimaker, BCN3D, Zortrax manufacturers to provide more reliable printing of BASF Ultrafuse 316L material for applications of printing metal parts with Desktop 3D Printers.

Drywise used as a development tool in project between Aquafil, Lehvoss and Ultimaker to make fully recyclable material 3D printable. In this example Drywise is the only tool that makes circular material 3D printable. Due to its high humidity, the only way that it can be dried is immediately before 3D printing.

E.E: What products / solutions were used in these projects?

A.A.L: In these projects, Magigoo adhesive solutions were used to ensure successful prints and minimize print failures. Drywise was employed to maintain the integrity of the materials and ensure consistent print quality.

E.E: What was the feedback from users?

A.A.L: Feedback from users has been overwhelmingly positive. Customers praise the reliability, ease of use, and effectiveness of Magigoo adhesives, as well as the enhanced print quality and material longevity provided by Drywise machine.

E.E: How can users work more sustainably with your products / solutions?

A.A.L: Users can work more sustainably with Thought3D’s products by reducing material waste, minimizing energy consumption, and ensuring consistent print quality. Magigoo helps reduce the number of failed prints, while Drywise inline filament dryers remove excessive moisture from 3D printing materials, improving their printability and reducing issues related to moisture content.

E.E: What are your forecasts for the first half of 2023?

A.A.L: Thought3D’s forecasts for the first half of 2023 include continued growth in the adoption of 3D printing technologies across various industries and educational institutions. The company expects increased demand for reliable, user-friendly solutions like Magigoo and Drywise, as well as potential expansion into new product categories and markets to cater to the growing needs of the 3D printing community. With the increasing awareness of the importance of proper material handling and processing, Drywise is expected to play a critical role in ensuring optimal print quality and consistency.