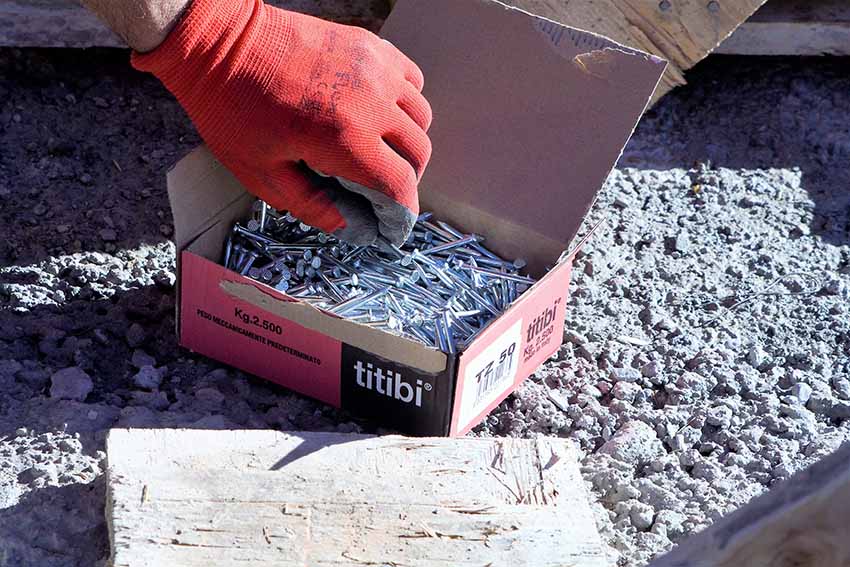

TITIBI s.n.c. is the manufacturer of the titibi range, which includes hardened steel nails, concrete nails, as well as tools and accessories – supplying customers in North America, Asia, the Middle East, as well as its main markets in Europe.

With more than 1,500 types of nails, in different sizes, titibi is predominately known for concrete nails that offer unique capabilities. titibi concrete nails combine a high hardness (54HRC – 57HRC with tolerances for each batch of 1HRC) with an elasticity that enables the nails to be deformed at a bending angle greater than 90 degrees.

titibi’s quality is thanks to a commitment to the highest quality materials; continuously searching for innovative technological processes; as well as the careful heat treatment and constant control of the mechanical characteristics of the finished products

Easy Engineering: What are the main areas of activity of the company?

TITIBI: Our biggest market is the construction industry. We manufacture our products for large construction companies, hardware stores and building material stores.

A small part of the production is instead destined for the DIY market.

E.E: What’s the news for 2020 about new products?

TITIBI: In the last year we have invested in the sale of gas nailers for concrete and particular nails dedicated to them. We are already very active on the foreign market of these products and we are also experiencing strong growth in the national territory in the last year.

The main challenge we face every day is to maintain our quality rate, trying to improve day after day. Quality and production flexibility are our strong point, and they are what allows us to differentiate ourselves from the competition

E.E: What are the ranges of traded products?

TITIBI: We produce over than 1.500 different concrete nails. Each country in the world has different requirements and thanks to our production feasibility, we are able to satisfy a large amount of different inquiries.

Since 1972, our company has gone from the production of iron nails to the production of only nails in hardened steel. At now, we are one of the biggest manufacturers of hardened steel nails in Europe.

E.E: At what stage is the market where you are currently active?

TITIBI: The construction market in Italy is quite flat. Our strength however is the foreign market. About 80% of our production is destined for abroad. Even in these difficult times, dictated by the pandemic, our business is growing thanks to numerous customers around the world.

E.E: What can you tell us about market trends?

TITIBI: The market forecast in this period is a bit uncertain. This is because of the pandemic that is currently unfolding around the world and the fact that it is unpredictable. The cost of raw materials is certainly on the rise and will continue to grow until the first months of 2021.

E.E: What are the most innovative products marketed?

TITIBI: Es explained before, we are investing into gas nailers market and These nailers are destined to revolutionize the classic nail fixing system, making the job much simpler and extremely faster. This is the future.

E.E: What estimations do you have for 2020?

TITIBI: 2020 was a difficult year. Not just for us, but for many companies around the world. There have been several lockdown periods which have put a strain on the strength of these companies.

We in Italy had to stop production for 2 full months from March to May 2020 due to the pandemic. This affected our growth this year a lot and caused a slowdown. However, despite these months of total shutdown, we still maintained contact with our customers and as soon as we reopened, we did our best to recover the accumulated delays. Currently, the amount of work is considerable and we believe we will close this 2020 with good results. We hope that after the winter the pandemic can go down and return to normal life next year.