TurboFil is an equipment specialist dedicated to the design and development of liquid filling and assembly machines for the pharmaceutical, medical device, health & beauty and chemical industries. Since its inception in 1999, the company has created novel, durable production solutions for some of the industry’s most challenging applications, consistently setting new benchmarks for filling precision and operational simplicity.

TurboFil’s equipment portfolio features a broad range of standardized equipment, and they frequently collaborate with customers to develop, design and construct customized, built-to-spec machines. This versatility has made TurboFil a leader in supplying reliable, efficient and cost-effective filling and assembly systems that fit seamlessly into existing operations.

Easy Engineering: What are the main areas of activity of the company?

TURBOFIL: Since TurboFil services a broad range of industries – everything from pharmaceuticals, nutraceuticals and medical devices to the health & beauty and chemical sectors – our product range is particularly diverse. Historically, though, we certainly have a few areas of specialty. One is in liquid filling, whether that be for a vial, bottle/container or syringe/injectable platform. Another is capping and crimping, where our solutions ensure that containers for high-leverage products are safely and securely applied. Precision labelling application and product handling solutions are two additional niches.

Regardless the specific solution, though, our systems are generally tailored to meet specific customers’ needs, at least to some degree. Sometimes this means relatively simple alterations to an existing system; other times it means a machine completely designed, developed and installed with one customer’s needs in mind.

E.E: What’s the news about new products?

TURBOFIL: TurboFil is consistently developing new, even customized solutions for complicated manufacturing scenarios. Two recent examples:

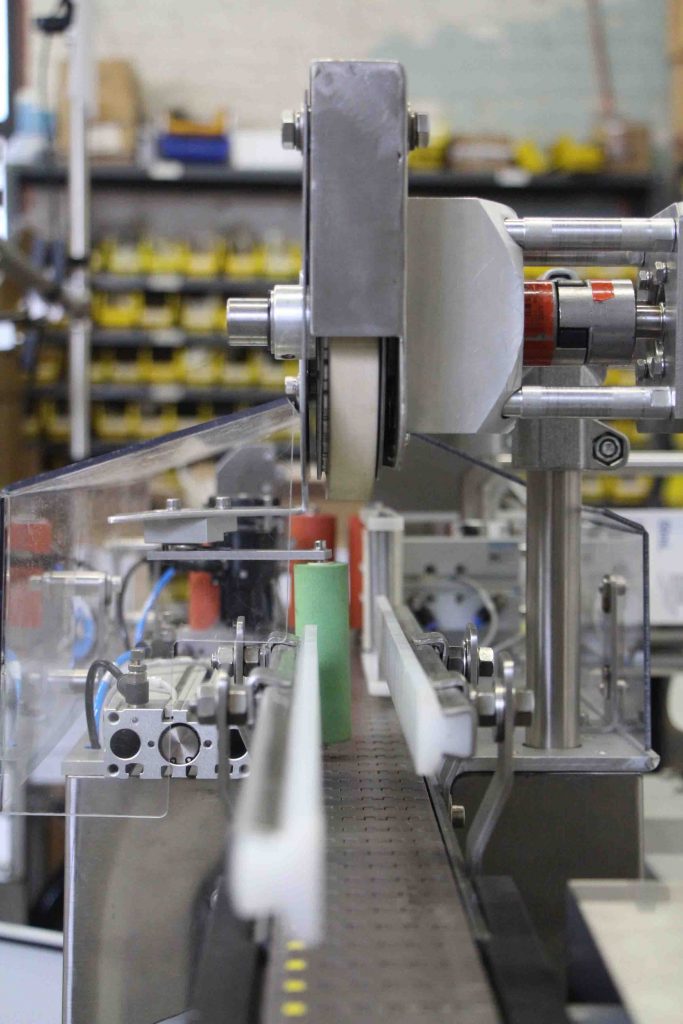

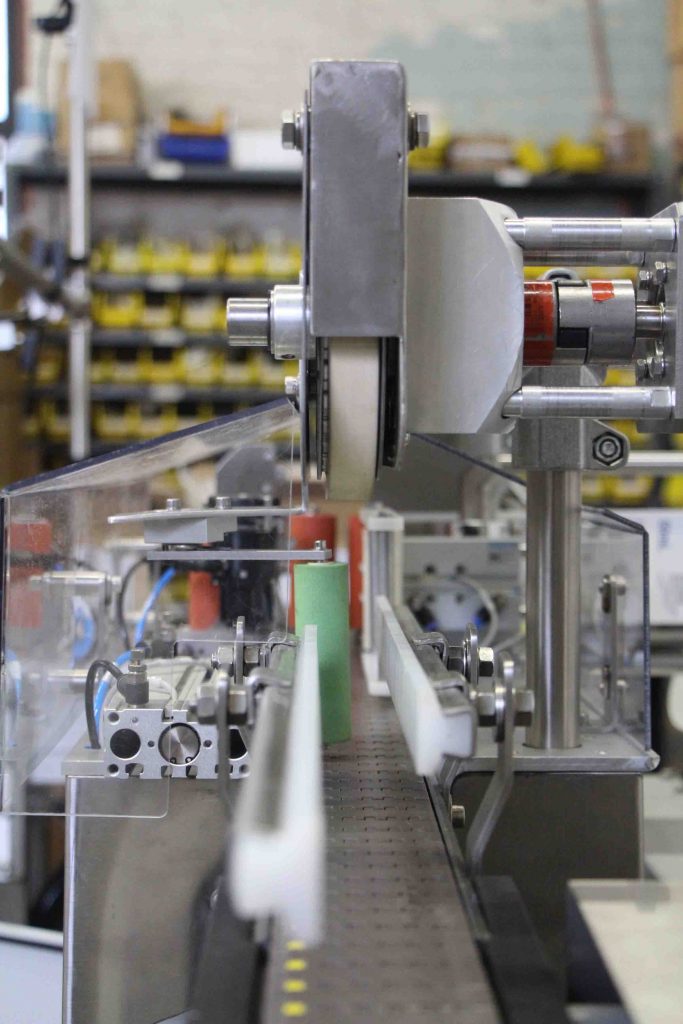

The In-line Dual Syringe Labeler is a wraparound unit that automates the often complex, labour-intensive process of dual syringe cartridge labelling. The machine reliably, repeatably and accurately affixes labels around one or both cartridges in two-syringe systems.

The Mini-Monoblock MDN-50 is an automatic machine for the inline filling & capping of multi-dose nasal dispensers. Optimized from the inception of the filling process to its conclusion, the unit accurately and expediently fills, seals, caps and labels nasal spray containers at a rate of up to 50 pieces per minute.

E.E: At what stage is the market where you are currently active?

TURBOFIL: TurboFil is heavily involved in the prefilled syringe market, with several products dedicated to filling glass and plastic syringes with high- and low-viscosity products. This is one of the most rapidly growing areas in pharmaceuticals, expected to continue its recent 10+% CAGR. In general, the market for pharmaceutical and medical packaging equipment is estimated at about $800 million in the United States alone.

E.E: What can you tell us about market trends?

TURBOFIL: Especially for pharmaceuticals and medical device applications, flexibility is becoming crucial. Many machinery suppliers work in areas that are highly specialized, necessitating exacting trials and, once production commences, yield only limited, often versioned runs. Amid this landscape, it’s important to have multi-purpose machines that can quickly pivot to perform other related production tasks rather than resting idle. For example, TurboFil’s SimpliFil Syringe Filling & Assembly System, a module for automated, uncomplicated production of a wide range of syringe formats. Employing a versatile yet precise setup that accurately fills syringes via ceramic piston, peristaltic pump or direct draw from a reservoir bag, the unit is suitable for small to medium batches.

On the other side of the coin, highly specialized, customer-specific machines also are increasingly in demand. This exemplifies the hyper-customization of medicine in general, including the growth in medical device + drug combination products.

E.E: What predictions do you have for 2023?

TURBOFIL: The markets for TurboFil’s equipment shows no signs of slowing over the next year, even despite the expected recession. The move towards automation in all parts of the pharmaceutical manufacturing chain portends well for growth this year and into the future.