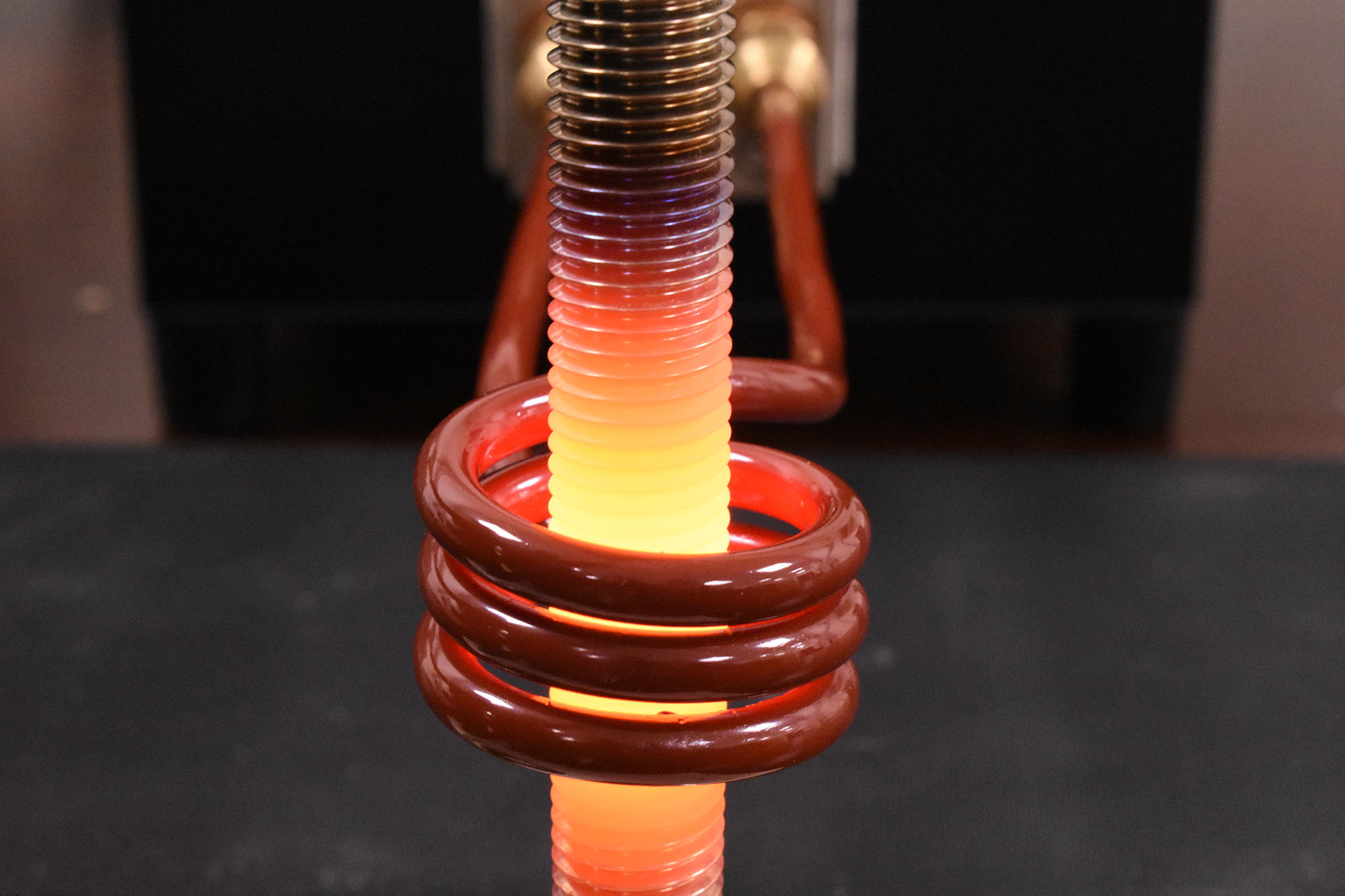

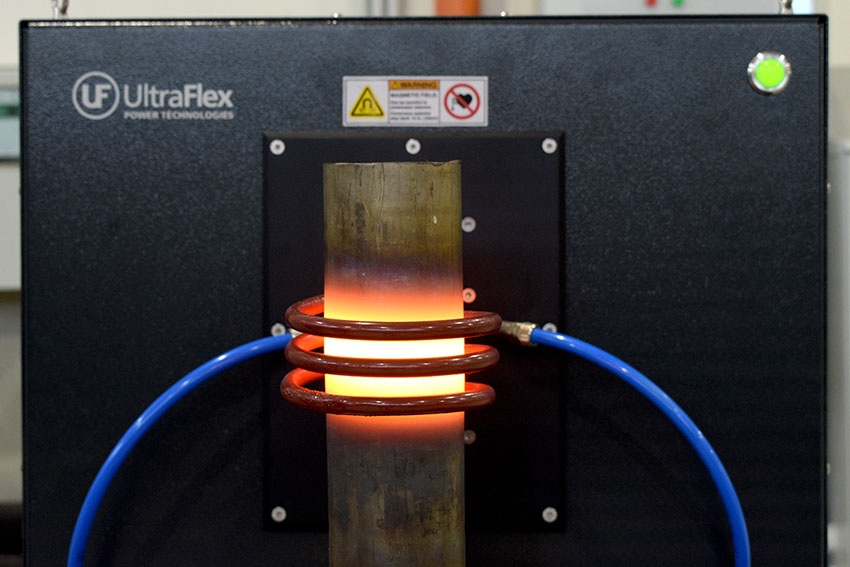

“Where induction meets innovation.”UltraFlex Power Technologies is a global leader in industrial induction heating equipment and systems. The company designs and manufactures advanced induction heating power supplies and systems – including their patented modular induction SmartPower system.

With development, manufacturing, and support centers in the USA, Europe, India, and South America, UltraFlex Power Technologies supports customers worldwide with system design, installation and support.

Interview with Nedelina Metodieva, Project manager at Ultraflex Power Technologies

Easy Engineering: What are the main areas of activity of the company?

Nedelina Metodieva: Ultraflex Power designs and manufactures industrial induction heating power supplies and systems. We are committed to using the latest in Sic transistor technology to offer our customers the most energy-efficient induction generators.

E.E: What’s the news for 2021 about new products?

N.M: In 2021 we have introduced our patent-pending modular induction heating system – SmartPower. The Sic transistor technology allows the power transistors to maintain semiconductor properties at much higher temperatures than silicon transistors, making the induction heating systems more efficient.

It also allows the induction generator to be upgraded for higher power if the needs of the customer change. It can also be used to develop a new induction heating process and then be upgraded for production use.

E.E: What are the ranges of products?

N.M: We manufacture a full range of induction heating systems – from 2kW to 800 kW. We also manufacture stand-alone induction casting and melting systems.

E.E: At what stage is the market where you are currently active?

N.M: Ultraflex Power currently serves industrial markets – including automotive, appliance manufacturing, tools and equipment manufacturing, fasteners manufacturing, and oil and gas.

E.E: What can you tell us about market trends?

N.M: The pandemic situation has affected many aspects of our business, but we are seeing an increased need for using green energy and induction heating as a green alternative.

An increased number of customers are also looking to automate their induction heating process.

E.E: What are the most innovative products marketed?

N.M: We have introduced the induction heating robobraze product, allowing customers to use cobots or robots in their induction brazing application.

E.E: What estimations do you have for 2021?

N.M: We expect the use of induction heating and automation of induction systems to increase in 2021. The availability of new transistors to be used in high-temperature environments and the move for more eco-friendly and sustainable ways to heat metal will be key factors in the growth in this sector.