ultraTEC innovation GmbH produces very innovative machine to deburr with ultrasonic. The original idea of using the technology of ultrasonic for deburring was born during an internship of Jonas Münz (son of Dieter and Iris Münz). Part of his internship was to deburr bone screws made of titanium by hand. This made him and a friend of him (Jakob Rehberger) to develop an automated deburring machines for bone screws as a Jugend Forscht project. The two young researchers received the 2019 Federal President’s Award for their exceptional work.

The project was supervised from the very beginning by Dieter Münz. For him, the project and the results were too important to be left on the shelf. Therefore, he develops the idea from Jonas Münz and Jakob Rehberger further and developed marketable machines and founded in May 2019 with his wife, Iris Münz, the start-up ultraTEC Anlagentechnik.

Since that time, they are developing, manufacturing and selling ultrasonic deburring machines and constantly developing their machines further. On July 1, 2022, the sharpening specialist VOLLMER joined ultraTEC with a majority stake. Since then, they are operating as ultraTEC innovation GmbH. With VOLLMER as major stakeholder, they could gain a strong partner at our side who comes a lot of experience and a global sales and service structure!

Interview with Thomas Benzing, Head of Sales at ultraTEC innovation GmbH.

Easy Engineering: What are the main areas of activity of the company?

Thomas Benzing: As there are many areas, where burrs occur during production, ultraTEC is active at many different areas.

Nevertheless, we see three main areas in the future:

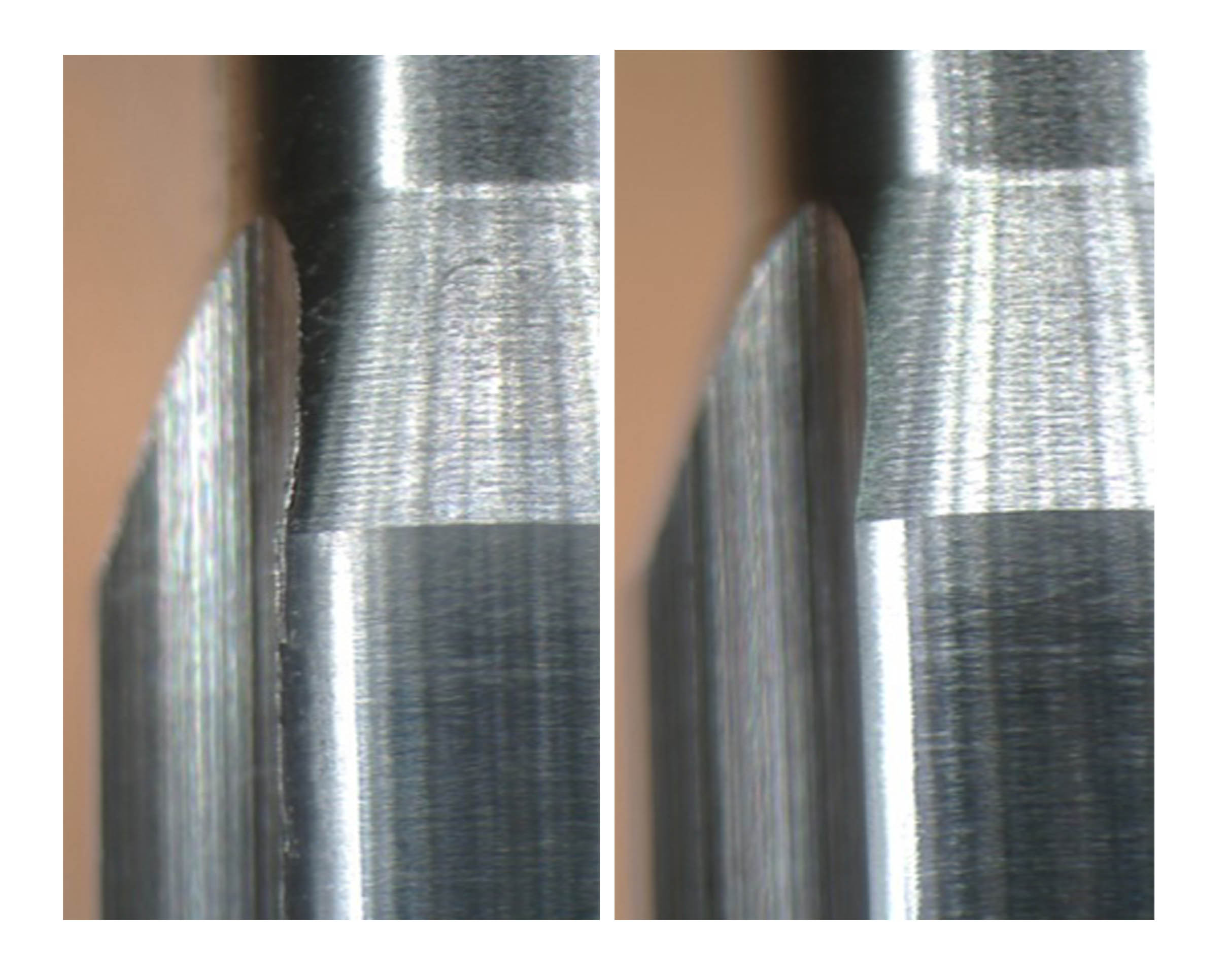

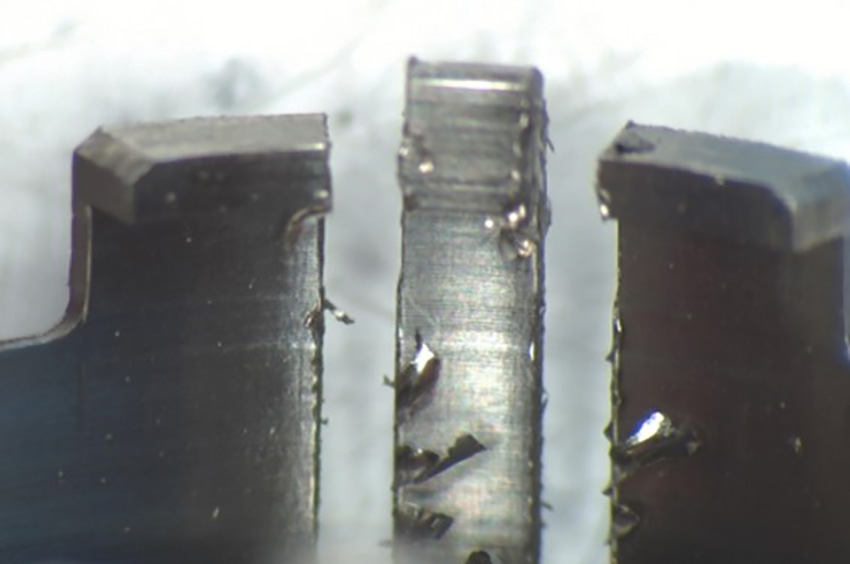

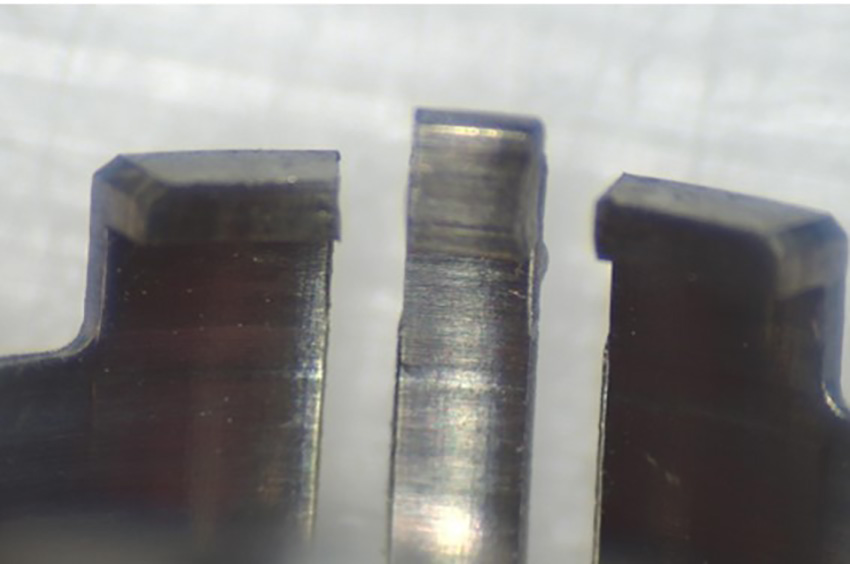

High precision parts – Whenever parts gets produced with a tolerance of less than 0.01 mm, other automated methods of deburring are reaching their limitations as all those methods including an uncontrolled removal of material from the component. Therefore, those methods are not suitable for high precision parts. We do have a different situation with deburring via ultrasonic as this technology enables a punctual deburring of the components! Therefore, we see big added value for customer with such kind of components with our machines!

Medicine products – For product that are used in the medicine, it is mandatory to ensure that there is no chance that burr will break-out when it is used! Therefore, the deburring process is very important in this area. Furthermore, main materials that are used in this area (like titanium) are very good to deburr with ultrasonic. Additional on that, we are cleaning the components to a certain level, which is also very important for this product. Las but not least, our process is validatable, a very important request from the medical technology industry.

Cutting-tools – With our new partner VOLLMER, we can fall back on a partner with very long and deep knowledge in the area cutting tools. Customer from VOLLMER and ultraTEC can only profit from this partnership. Very interesting applications for cutting-tools for our machines are i.e. deburring of HSS-tools; inner cooling pipes; pocket-seats of tools. Furthermore, ultrasonic deburring is an automated alternative to the manual glass bead blasting of PCD-blanks

E.E: What’s the news about new products?

T.B: So far, the technology ultrasonic was in the industry mainly known for cleaning purposes of part. But now with the machines from ultraTEC, we are adding another application of the ultrasonic technology, which is the deburring process of parts.

With this innovative technology, we are able to offer our customers the advantage of an automated, almost material independent, non-contact, energy efficient and validable deburring process. This is unique on the market! Compared to alternative deburring methods, ultrasonic offers the following advantages:

Thermal deburring processes for example, burn off burrs, which can discolor and chemically change materials.

ECM (electrochemical metal machining) processes are often not possible for small components because they cause material removal that cannot be defined.

Deburring with a high-pressure water jet requires about 20 times more energy compared to our machines.

E.E: What are the ranges of products?

T.B: We can divide our ranges of products in model A and model B. Model A machines are equipped with a water process basin, whereas the ultrasonic horns are installed in the basin. Parts to be deburred get loaded with a robot arm and placed in the process water to the ultrasonic horns. This machine type is designed for tools that can be grabbed with a gripper.

The model B machine turn this process around. The ultrasonic horn is mounted on the robot arm and the parts are placed in the process water basin. The flexible robot -arm allows to drive with the ultrasonic horn alonge the parts and to deburr them. This type of machine is designed for parts, that can´t be grabbed with a gripper, micro parts i.e.! Beside this standard machine, we are also offering special designed machine according to the customers’ requirements.

E.E: At what stage is the market where you are currently active?

T.B: The technology ultrasonic deburring is very new! ultraTEC is the only company, that offers marketability machines for automated deburring with ultrasonic.

E.E: What can you tell us about market trends?

T.B: A lot is deburred still by hand.

Work resource-saving and environmentally friendly + saving energy costs gets more and more important!

E.E: What are the most innovative products marketed?

T.B: Model A (A25 + A100) – ultrasonic horns are installed in process water basin.

| A25 | A100 | |

| Dimension of components | 150x150x150 mm | 300x300x300 mm |

| Weights of components | Up to 2 kg | Up to 20 kg |

Model B (B10) – ultrasonic horns are installed on robot arm

| B10 | |

| Dimension of components | Starting with 1x1x1 mm |

| Weights of components | Up to 5 kg |

E.E: What estimations do you have for the rest of 2022?

T.B: We are looking very positive to the rest of this year and also to the year 2023! We feel that there is a very big need of automated deburring machines! Furthermore, with the new partnership with VOLLMER we could increase our sales and service network and will be able to offer our machines for internationals markets.