For over 30 years, VGS works in the manufacturing industry and digital customizing of boards, décor and contract.

Interview with Luca Capponi, Sales Manager at VGS SRL.

Easy Engineering: What are the main areas of activity of the company?

Luca Capponi: Our company is specialized in customization of décor elements for hotels, schools, show rooms, clothing boutiques, wellness shops and supermarkets.

For furniture companies, VGS customizes furniture elements in general.

E.E: What’s the news about new products?

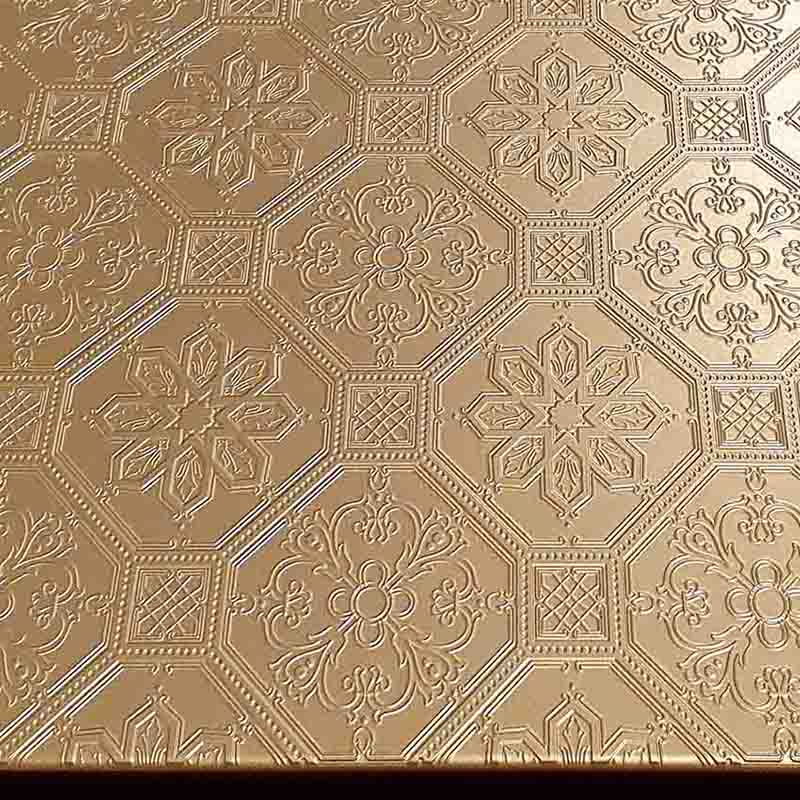

L.C: The Research and Development department in VGS, has developed DORSUM®, a manufacturing process that decorates varnished embossed panels.

In 2021 VGS obtained the Italian patent and has applied for the European certification.

DORSUM® has been developed thanks to a cooperation of world’s leader coating companies, such as ICA and RENNER.

DORSUM® is the only product of its kind to be patented.

The manufacturing process has also obtained Accredia certification for the furniture industry.

E.E: What are the ranges of products?

L.C: DORSUM® was initially created to decorate shutters and fronts of drawers, but now it can be used for other décor elements. For this reason, we developed new DORSUM® byproducts:

- DORSUM® Wd, specifically designed for embossed flat wood elements (MDF wood, chipboard and laminated wood);

- DORSUM® Kn, fire-resistant aluminium backsplashes for kitchens;

- DORSUM® Bm, laminated aluminium panels for bathrooms and shower enclosures;

- DORSUM® Gs, embossed finish on glass elements.

We are currently studying new products that will be launched on the market in 2023.

E.E: At what stage is the market where you are currently active?

L.C: The customization market has always been hard to predict because of the production costs and outdated technologies.

Technologies today have finally high production values and production costs have decreased and the market has a better thought on customizing individual elements or full items.

E.E: What can you tell us about market trends?

L.C: Thanks to DORSUM®, we can customize infinite décor elements, with different thickness and endless variations of colours and surface finishes.

Thanks to DORSUM®, we overcame the limits of furniture finishes. The types of panel finishes that are currently on the market are almost all the same, but DORSUM® is the real innovation.

E.E: What are the most innovative products marketed?

L.C: DORSUM® is obviously our breakthrough product, but we also create large-scale BRAILLE materials with high thickness for visually impaired people, that can be directly applied on furniture elements to make their life easier in their home or in a hotel room.

Another innovative product we created is “Mattonellato” (tile finish), a chemical resistant light panel certified by Accredia. This product can be used in damp and wet working environments, such as supermarkets or kitchens. Mattonellato is suited for quick renovations where there can’t be opened construction sites.

E.E: What estimations do you have for 2023?

L.C: VGS really believes in its main product, DORSUM®, and since 2021 our company is investing in online and offline marketing campaigns through social media and exhibitions.

In 2022 we saw the market appreciate our breakthrough product, DORSUM®, and we hope in 2023 as a year of growth.