Viappiani Printing is a major player in the world of IML label printers with more than 35 years of specific IML experience. Since 2009, Viappiani is member of the CTI Group, an Austrian privately owned international group being active in various branches of packaging printing.

The plant and offices are conveniently located very close to Milano, to airports and motorways.

The printing machines are offset presses up to 8 colors plus varnish and are served by an internal repro department. The finishing area includes all types of punching and die-cutting technologies and the whole company operates on an area of 25.000 square meters.

Interview with Stefano Di Gregorio, Technical & Business Development Manager at Viappiani Printing.

Easy Engineering: What are the main areas of activity of the company?

Stefano Di Gregorio: Viappiani used to print several types of labels but since 2013 we produce exclusively in-mould labels with a clear focus on labels for food packaging representing about 75% of the production. Within the food products the ice cream packaging is the biggest runner. The remaining 25% is given by IML labels for chemicals.

We care very much about assisting the customer in his whole IML experience, i.e. we like to be with the customer from the very beginning of the project for designing the container, the label area and the label specs. What we offer is a couple of eyes more looking at all the details and an additional printer’s perspective. We know very well that a good design of a packaging is half of the success.

As soon as we talk about labels, we go even deeper, our experience allows us to guide the customer in the choice of materials and finishing for finding the best compromise between performance and costs.

Label design management is another aspect we can be helpful on. We are very experienced in managing huge numbers of designs of a single project for our customers and in optimizing the designs, like for example with color harmonization.

Also, on improvement and optimization projects we are often at the customer’s premises. They simply call us; they know our goal is their success.

The main geographical market is Italy, and the European countries sum up to more or less the same figure. Anyhow we also cross oceans with our sales. We care about our customers and try to assist them in their own language, both for our salesmen and for the day-to-day operation of our customer managers.

E.E: What’s the news for 2021 about new products?

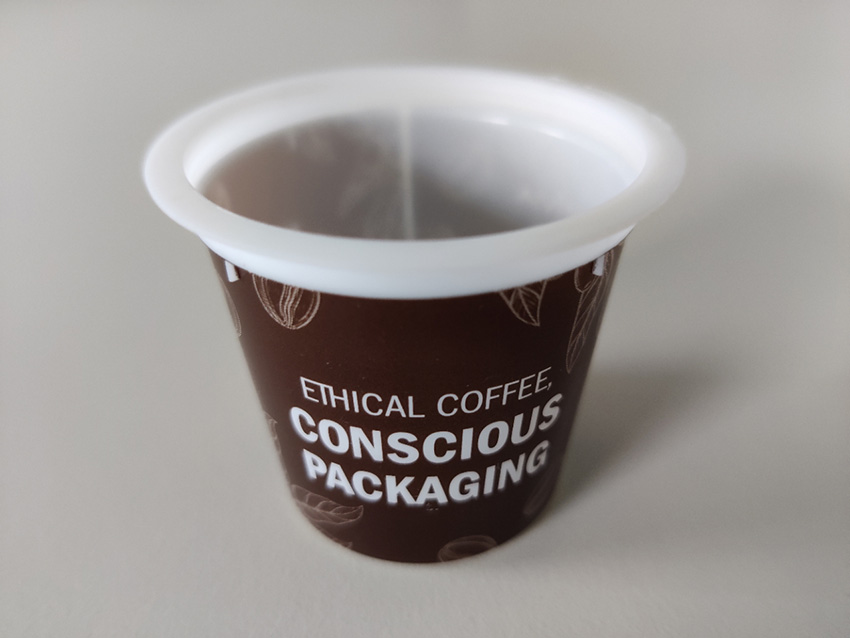

S.D.G: The latest development of Viappiani is a Home Compostable IML Label. A special pulp of natural fibers is printed almost like a normal IML label and is used to be moulded on containers or plastic parts made of home compostable injection material. The ideal products for this kind of technology are single serve coffee capsules. IML’s general philosophy of a monomaterial labelled container is replaced by the concept of the common end of life, in this case composting, be it industrial or home composting, we can do both. The used coffee capsule goes straight into humid waste: capsule, IML label and brewed coffee, without the need of separating any component.

E.E: What are the ranges of products?

S.D.G: The IML labels produced by Viappiani can be printed up to 8 colors plus varnish and might be tailored to be used for example on ice cream containers (refrigeration resistance) or on containers which will be pasteurized (heat and moisture resistance). The sizes of the labels range from a hand full of centimeters square up to a single big label which can fill a 75 x 106 cm printing sheet. These big labels for paint buckets require specific label films and finishing techniques and represent the second product category for Viappiani.

E.E: At what stage is the market where you are currently active?

S.D.G: The European IML market is quite mature but still growing; slightly higher growth rates can be seen in Americas and Africa, but also in Asia.

Beyond the current growth trend, there might be new opportunities given by the growing environmental consciousness. Yes, I mean that our environment and our economy do not ask for eliminating plastics, they ask for a good management of plastics. The hashtag #plasticfree is quite common today, but not necessarily right. Mechanically recycling plastics is the most cost effective and environmentally friendly way to get to a second life of a product. Generally, much more than substituting plastics with other kinds of materials. In-mould labelling perfectly fits this frame. An IML labelled container is (with just very few exceptions) a monomaterial plastic part, this means we can recycle the container without the need for removing the label.

What can you tell us about market trends?

The two main trends in IML are basically the same of any other industry: cost optimization and sustainability. The first means probably leaving premium finishing of the label (like for example UV varnish or foiling) in favor of technical performance and optimized costs.

The second is sustainability as a very trendy word nowadays. In order to be sustainable, companies are willing to invest some money, be it just to sound sustainable or to really be it. Yes, unfortunately in some cases the appearance is more important than substance…

Another recent market trend is codes of different types. 2D codes like Datamatix or QR codes appear more and more frequently on label artworks in order to either inform the customer or for traceability purposes. As far as digital watermarks are concerned, for example Digimarc codes, we are in an evolving world. GTIN coding is reality at a couple of retailers and support to recycling systems is in an advanced development stage. But this is not all, traceability, end user management …the possibilities are endless.

E.E: What are the most innovative products marketed?

S.D.G: The innovations of the last years were created around the concept of sustainability. A product presented a couple of years ago at the NPE exhibition in Orlando USA is a K-size coffee capsule injected with compostable PLA material and labelled with a compostable PLA IML label. This solution ensures industrial composability.

Another project we have developed is an ice cream container which is labelled with a removable IML label. The concept behind this project is to produce a container which once used can become, by peeling off the label, a reusable container for the fridge. This way we transform a single use container into a multi use container.

Another quite popular project over the last couple of years is lids with integrated spoon for monoportion. In this case we range from clipped wooden spoons to integrated PP spoons with fully removable food grade IML label.

E.E: What estimations do you have for 2021?

S.D.G: For 2021, we estimate for sure some growth. We still have to recover some volume decreases of 2020 in the nonfood area due to the Covid pandemic and we have some new projects at the horizon. We look forward to new challenges.