Under the brand Lizzini, Wallram Grindtec develops, manufactures and sells high-precision grinding machines for internal, external unround as well as profile grinding. Lizzini’s foundation dates back to 1945, when the brothers Arturo and Giacomo founded the company in Brescia. Wallram Grindtec is placed since 2008 in a modern facility in Montichiari, close to Lake Garda.

The firm is part of the international group Wallram, a group led by Hans-Peter Kämpfer that can claim plants in Germany, Poland, United States and Italy.

The company manufactures grinding machines tailored on customers’ demands and flexibility is one of their main skills, really appreciated by their customers.

Easy Engineering: What are the main areas of activity of the company?

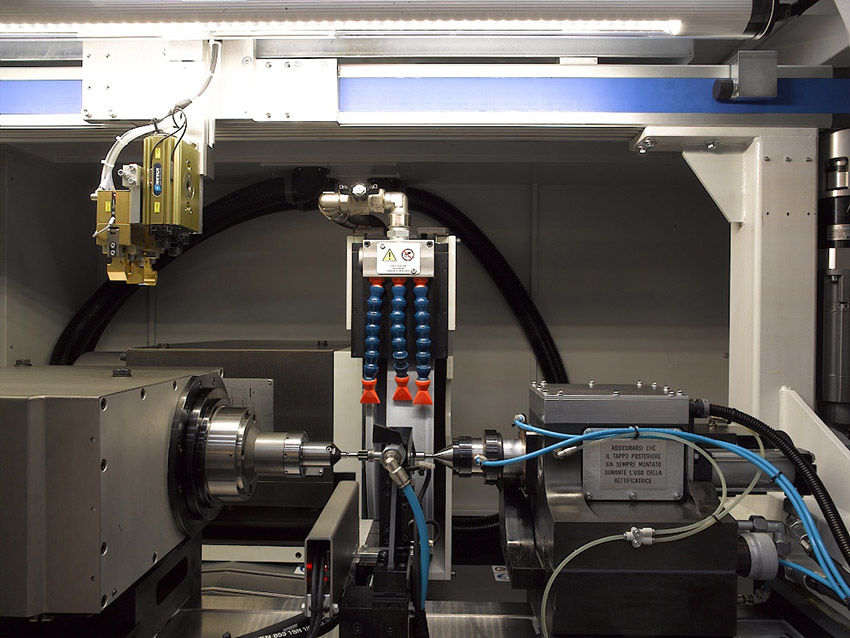

Wallram Grindtec: The main activity of our firm is the manufacture and sale of high-precision grinding machines. At Wallram Grindtec we evaluate the requirements of every customer in order to please them with the best fitting grinding machine. We produce internally most of the components assembled on our grinding machines, which are integrally designed by our technical office. The components which are not directly produced by Wallram Grindtec are provided by the best suppliers in the industry. The quality of every element installed on our grinding machines is a staple for Wallram Grindtec. We are present on different markets worldwide and we supply many industries different from one another: the aviation industry, the automotive industry, the tool construction industry, the medical industry and the chemical industry are the most relevant.

E.E: What’s the news for 2020 about new products?

Wallram Grindtec: The most important news for 2020 is a new entry in our universal grinding machines portfolio. Our portfolio was very complete: we had the IG FS grinding machines suitable for grinding pieces with 500 mm maximum length, then the IG FL to grind pieces with 800 mm maximum length, the IG FL to grind pieces with 1000 mm maximum length and last but not least the IG FXL to grind pieces with 1500 mm maximum length. Not to forget the internal grinding machines portfolio, with the IG IS, the IG IM and the IG IL. Nevertheless, we were missing a small, compact grinding machine. That’s the reason why we decided to develop the brand new IG FXS, suitable for the grinding of small pieces: max. 250 mm length. This new grinding machine is perfect to reduce the floor space requirement: it’s 25% smaller compared to the IG FS!

It goes without saying that also this grinding machine is extremely customizable and tailored on customers’ requirements: almost every optional can be personalized.

E.E: What are the ranges of traded products?

Wallram Grindtec: The range of our products is wide and designed to meet customers’ expectations. We have 5 universal grinding machines, grouped according to the maximum grinding length of the pieces. The IG FXS is the smallest: the maximum grinding length is 250 mm but its strength is the size, because it’s extremely compact and suited for firms looking at reducing floor space requirements. Then we have the IG FS, which is the second smallest and has a maximum grinding length of 500 mm. The IG FM is slightly bigger than the IG FS, its maximum grinding length is of 800 mm. With the IG FL we reach the grinding length of 1.000 mm and ultimately, we have the IG FXL which is able to grind pieces with 1.500 mm maximum length.

The model of the grinding machine is just the starting point, because customers can choose across many different options and design the grinding machine according to their needs: mineral or natural granite bed, with or without B-axis, the grinding spindle head configuration, the height of the workhead, manual or automatic tailstock, measuring devices, software Micron or GrindSELECT, with or without automatic loading systems, and many other options at the discretion of the customer.

This was just the range regarding universal grinding machines, because in Wallram Grindtec we also manufacture internal grinding machines. We have 3 models: IG IS, IG IM and IG IL. The discriminating factor is the size of the piece that we can grind with each of these grinding machines. With the IG IS the maximum grinding length is of 200 mm, the IG IM can grind pieces with maximum 300 mm length and the IG IL has a maximum grinding length of 400 mm. All three are provided with a natural granite bed, the best technology available on the market up to now.

E.E: At what stage is the market where you are currently active?

Wallram Grindtec: We see some customer struggling, mainly for automotive industry situation.

Other fields, like medical, energy or hard material industry seem to have better conditions. Fortunately, Wallram Grindtec works on a wide range of fields, for that reason we can rely on a solid foundation and we’re not so dependent from changes within a particular field.

E.E: What can you tell us about market trends?

Wallram Grindtec: Many customers (much more than in the past) look for automatic loading systems on their grinding machines. With this solution, they’re able to increase production and reduce cycle times. We also see another trend: many customers want to bring back to the company machining processes formerly made by external suppliers. This also applies to grinding processes.

E.E: What are the most innovative products marketed?

Wallram Grindtec: The most innovative product marketed is our grinding machine with hydrostatic guides. There are many advantages in using hydrostatic guides: they are wear-free, extremely precise even at high-speed and ensure an excellent damping with no vibration. We introduced this technology in 2017 and we look forward to continue its development in the following years because we think it can be an interesting solution for the future.

The software is a key feature for the future, everything nowadays works by means of a software. Flexibility in the use and the chance to load 3D files directly to the operative panel are features that are already available on Wallram Grindtec machines.

E.E: What estimations do you have for 2020?

Wallram Grindtec: 2020 has been a tough year for the industry in general. Especially in Italy, with such a long lockdown, the situation has not been easy. But we see that after a period of uncertainty following the re-opening of industries, customers are more confident in the future and ready to invest in grinding machines. We have many requests for quotes, both for upgrades of grinding machines installed in the past and for new grinding machines. We perceive that customers are trustful and want to leave behind this difficult period in order to continue their businesses.