Werkzeugbau Ruhla GmbH is a traditional German manufacturer of multi-cavity, high-precision injection molding tools (molds) for the production of plastic parts used in the medical, diagnostics, laboratory and packaging industries.

Easy Engineering: What are the main areas of activity of the company?

Werkzeugbau Ruhla: Multi-cavity injection moulds are manufactured for the production of various plastic parts, such as:

- Syringes especially for self-destructing disposable syringes in various sizes and designs;

- Pipettes, blood lancets, infusion systems;

- Safety pin, caps, fasteners;

- Other plastic parts for biochemical, pharmaceutical, laboratory, cosmetic and packaging use.

Werkzeugbau Ruhla GmbH is looking for a potential new partner. We are interested in the manufacturers of plastic injection molded parts for the fields of medicine, diagnostics, laboratories or packaging.

E.E: What’s the news about new products?

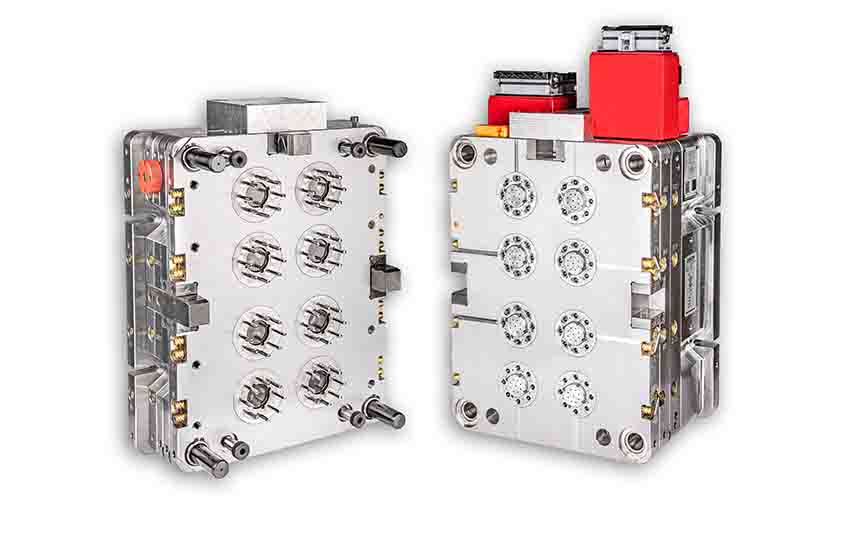

Werkzeugbau Ruhla: Injection moulds for new light self-destructing disposable syringes with 3-winged plunger that are up to 30% lighter than conventional plunger, see attached image.

E.E: What are the ranges of products?

Werkzeugbau Ruhla: Full hot runner injection moulds, mostly 64-cavity for disposable medical items.

E.E: At what stage is the market where you are currently active?

Werkzeugbau Ruhla: We are special machine builders, only for multi-cavity molds and cannot speak for the entire market situation.

E.E: What can you tell us about market trends?

Werkzeugbau Ruhla: If possible, the plastic articles should become lighter and be able to be produced more quickly.

E.E: What are the most innovative products marketed?

Werkzeugbau Ruhla: Molds for our light self-destructing disposable syringes with 3-winged plunger.

E.E: What estimations do you have for the rest of 2022?

Werkzeugbau Ruhla: To be fast, accurate and as productive as possible as energy prices will increase enormously.