Wiferion is the leading solution supplier for the mobile, wireless power supply of electric industrial vehicles. The flexible, scalable integration of their products eliminates unnecessary machine downtimes and high-maintenance, expensive wired charging. Users can thus sustainably increase their utilization and fleet efficiency by up to 32%. Consequently, AGV projects can be realized up to 30% more cost-effectively.

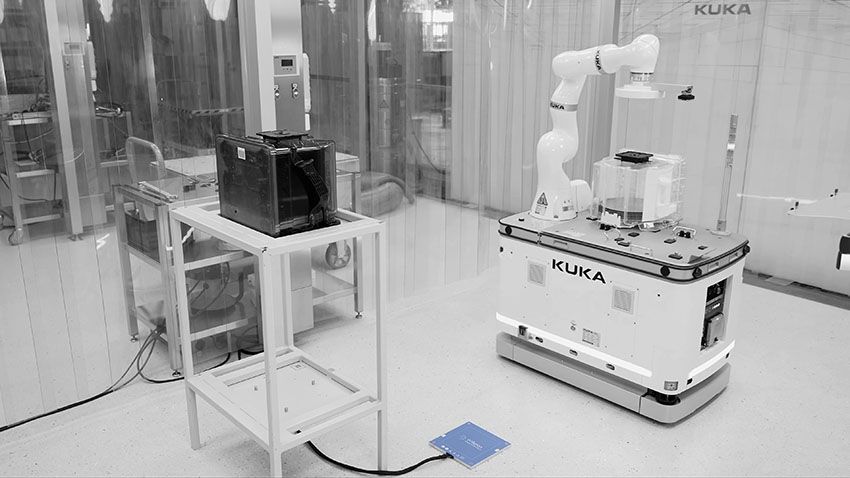

Countless companies in the logistics, industrial and automotive sectors rely on Wiferion’s technology. These include leading suppliers of automation solutions such as the robotics companies SAFELOG, KUKA and FlexQube. The battery charging systems are being used by over 100 OEMs and practically all the European motor manufacturers, plus the major logistics and e-commerce companies. The company has now sold more than 5000 of our etaLINK systems in over 20 countries.

The sale of the energy solutions focuses on Europe. Wiferion also opened a branch in Chicago, North America, in 2022. With this, the company is responding to the huge demand for its UL-certified charging systems in the US market.

Interview with Johannes Mayer, Board Member, Chief-Evangelist, Co-Founder at Wiferion.

Easy Engineering: What are the main areas of activity of the company?

Johannes Mayer: From inductive charging technology through to software-based energy management solutions, we offer a wide range of products that allow floor conveyor vehicles (FCVs), driverless transport systems (DTS/AGVs) and autonomous mobile robots (AMRs) to be supplied with energy efficiently.

E.E: What’s the news about new products?

J.M: For 2023, we are planning to launch our etaHUB energy management software. As an integral part of fleet management and ERP systems, etaHUB will export the energy data of the etaLINK systems. We are thus creating a digital energy supply twin that will help our customers to reduce their power supply and charging infrastructure costs. Ultimately, etaHUB is intended to be the standard and essential element of the smart factory, with Wiferion as an “energy as a service” supplier in the market.

E.E: What are the ranges of products?

J.M: Our product range includes the battery charging systems in the etaLINK series. The inductive fast charging systems are currently available with 3 kW and 12 kW output. In addition, there are the etaSTORE lithium-ion batteries (LFP and LTO) and, from 2023, etaHUB software for data evaluation for condition monitoring, predictive maintenance and energy and fleet management applications.

Johannes Mayer, Board Member, Chief-Evangelist, Co-Founder at Wiferion.

E.E: At what stage is the market where you are currently active?

J.M: We are seeing automation with AGVs and AMRs picking up speed all the time. The vehicles have now reached the stage where they are suitable for the mass market. We are assuming that this trend will become stronger over the next few years. Because the availability of the vehicles is crucial for the RoI of the projects, inductive charging will play a key role in this development.

E.E: What can you tell us about market trends?

J.M: Standardization is the next topic for the industry to deal with. So far, AGVs were predominantly project-based developments. Manufacturers like our customer Safelog, on the other hand, are clearly going for modular, standardized production of vehicles for the relevant applications. In this way, large numbers of items can be manufactured. Safelog, for examples, produces over 1000 vehicles a year. As a component manufacturer, we are obviously also going down this path and have aligned our charging systems to suit the needs of the OEMs. Our aim is to establish wireless charging as the standard for energy supply in production and logistics.

E.E: What estimations do you have for the rest of 2022?

J.M: Overall, 2022 has been a very successful year in which we as a company have once again recorded strong growth. The current overall economic situation will undoubtedly leave its mark in 2023, but it is difficult to predict now how great the impact will be on the industry for driverless transport systems. Basically, it can be said that the fundamental drivers for automation, i.e. the shortage of skilled workers (especially in logistics) and, against the background of rising costs, increasing productivity in companies through automation, are still very strong. To this extent, we are expecting mobile robotics to remain one of the high-growth branches of industry in the next few years.