WIKUS is one of the world leaders in the metal cutting sector and Europe’s largest manufacturer of band saw blades. Since 1958, WIKUS-Sägenfabrik from Spangenberg, Germany, guarantees highest standards in the production of high-tech band saw blades with high-quality raw materials, up-to-date manufacturing methods and continuous quality assurance.

At the same time, with its innovative power, the family-run business sets leading product and technology trends on the market. In addition to the high-performance product range, WIKUS offers comprehensive services which are adapted to each product. Partner companies as well as sales and service companies all over the world offer competent, personal support on-site and training classes online and offline.

Easy Engineering: What are the main areas of activity of the company?

WIKUS: WIKUS offers high-quality cutting tools for different industry areas. This includes steel production, steel trade, foundries, machine and tool construction, aerospace, automotive, construction, additive manufacturing and the energy industry. With its cutting solutions, WIKUS supports its customers worldwide to increase their efficiency and reduce costs in their sawing processes. WIKUS offers the specific product for every cutting application.

Furthermore, WIKUS supports its customers as a service and consulting partner. Experts who have an in-depth expertise about all aspects of sawing tasks offer to draw up an individual needs analysis so that they can make a recommendation for the optimum solution – before purchasing expensive tools and machines. The existing processes can profit from the WIKUS-support with respect to the matching product, optimum cutting parameters, the best possible settings on the available machine, material supply, post-processing and logistics.

To offer a comprehensive service for optimizing the sawing process, WIKUS is also involved in digital services for optimizing the cutting processes and supplementing the product portfolio. The innovative services comprise ParaMaster®, an online cutting data program, the WIKUS Blade Selector and the WIstore®, which helps to optimize the tool management. With these service tools, customers can concentrate on their core processes.

In addition to these services, WIKUS has established the training center WIkademy® in 2018 and teaches training courses that suit all levels of expertise. In their seminars and webinars, WIKUS experts share their knowledge on products and sawing applications. The trainings range from different areas of use and field applications of sawing processes as well as the latest industry trends in the sawing sector.

E.E: What are the ranges of traded products?

WIKUS: WIKUS is offering band saw blades with an outstanding wear resistance in conventional applications. The product spectrum ranges from bimetal to carbide and coated band saw blades for example. Within these product types, WIKUS offers entry-level models to powerful all-rounders, high-performance band saw blades and blades for high-speed cutting of solid, structural, case-hardened and heat-treatable steels in large series and mass cutting on high-performance sawing machines in challenging industry areas. Additionally, WIKUS has different precision circular saw blades that round up the product portfolio.

E.E: At what stage is the market where you are currently active?

WIKUS: WIKUS is internationally active in the metal market and provides their sawing solutions for a wide range of companies – from small workshop operations to large factories and high-tech industries with special requirements like the aerospace, automotive, construction or energy sector. The band saw blades are also tailored to the needs of the customers, i.e. the offered products range from entry-level blades to specialized blades for difficult and demanding sawing processes, whereby WIKUS always guarantees the “Made in Germany” quality.

E.E: What can you tell us about market trends?

WIKUS: For industries such as the automotive industry, aerospace and medical technology or the semiconductor industry, cutting processes with high-tech cutting materials will be a focus of research and development in the following years as the innovative materials used require enormous safety measures and demand a high level of quality from the saw blades. For tool suppliers of the high-tech industries like WIKUS reliability, process safety and long service life are core requirements. The band saw blades from WIKUS, which are specially coated with high-tech materials, meet precisely these requirements and are continuously being further developed. By using the high-tech sawing tools from WIKUS in combination with the service applications, the customer benefits from a significant cost reduction with a simultaneous increase in productivity. In addition, the customer has high-quality cutting tools with a long service life and great precision, which were developed for his special requirements.

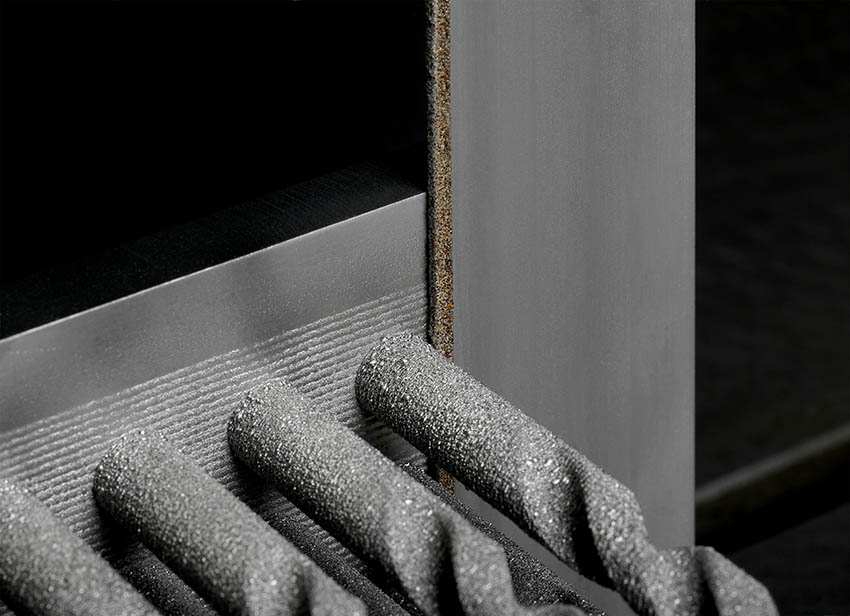

Another market trend is the growing technology of additive manufacturing. The number of possible applications is constantly increasing. Above all, the individualization of products, especially metals, the optimization of product properties and shorter production times cause companies to manufacture components and tools with 3D printing. In the following years, additive processes will also find their way into mass production. WIKUS offers different saw band solutions coated with high-tech materials, which can be used in additive manufacturing, for example to separate the printed workpiece from the support structure.

E.E: What are the most innovative products being marketed?

WIKUS: WIKUS has its own research and development sector, studying how to further develop their products and explore how to optimize the sawing processes. The company is consistently awarded for its research and development efforts. This commitment is reflected in WIKUS’ innovative products, for example CUBOGRIT®, PRIMAR® M42 and ARION®.

In 2019, WIKUS has released the new band saw blade CUBOGRIT® which is coated with the innovative material CBN (Cubic boron nitride). Its properties include high hardness and strength as well as thermal, chemical and abrasion resistance. CUBOGRIT® is the first CBN-spread band saw blade technology for the economical sawing of hard alloys produced by 3D printing and hardened ferrous materials of up to 70 HRC. Further special properties such as the absorption of loads und the use at high cutting speeds are due to the carrier material made of an alloyed hardened steel, which was developed exclusively for WIKUS.

With PRIMAR® M42, WIKUS offers users of a bimetal band saw blade numerous advantages such as a long service life and a wide range of use cases: It can be used for industrial cutting applications as well as in workshop operations for profiles and solid materials of all metals up to a thickness of 1,000 N / mm², which means that fewer belt changes are required. The M42 tooth cutting edge with adapted rake angle plus the optimized variable tooth pitch with standard setting ensure the usual WIKUS precision in the sawing process and lower noise emissions. The production process with superfinish increases the service life and process reliability. This allows to reduce the costs per cut and achieve a good price-performance ratio.

The ARION® band saw blade corresponds to the premium class of band saw blades. With its hard metal tooth edge with extremely wear-resistant hard metal coating and the ground trapezoidal tooth, it can be used in thin-cutting technology. The extraordinary blade stability leads to maximum precision, little material loss and precise flatness of the cutting surface. The use of the high-performance band saw blade leads to an increase in productivity through maximum cutting performance.

WIKUS: The process quality and stability during the production chain influence all subsequent work steps and thus also the process and cost efficiency. This is why the use of the right sawing tools is essential in a production process. WIKUS offers fitting band saw blades for every special need, a comprehensive consulting process to find the fitting tool for every individual cutting process and helps to build up an economic sawing process. Innovative products, latest technology accompanied by service tools, know-how and customer-oriented consulting are the specialty of WIKUS.