Wolfgang Krajewski was founded in 1971 by today’s senior boss Mr. Wolfgang Krajewski. Back then, the core business was pump retail and repairs. Mr. Krajewski actively extended the program of his company, leading to a constant and sustainable growth. His two sons Rene and Andre joined the Management of the company in 2003 and 2013, forming an experienced team of Managers with a profound hands-on mentality.

By now, Wolfgang Krajewski GmbH & Co. KG is a flexible SME company with a solid customer base and many completed and active projects. The scope of activities consists of planning and construction of electro machinery installations, stainless steel pipework and electrical controls. Thanks to the excellently skilled and experienced crew, the Krajewski family business today offers professional project processing, short reaction times and top quality labor. High quality products from brand name manufacturers support this quality approach, yet allowing for full flexibility due to non-exclusive long-term supply relations.

Easy Engineering: What are the main areas of activity?

Wolfgang Krajewski: The main areas of activity are:

The civil sector plays a major role – the Krajewski company supplies pumping equipment and pipe constructions in dewatering and sewage projects as well as dry and wet pit pumping stations.

Civil engineering and road construction companies are typical principals in large projects, we carry out delegated planning and construction activities of pumping equipment.

In the private processing industry, the focus is on repairs and replacing of submersible and dry-mounted pumps, compressors, blowers and other rotating equipment from the mechanical point of view. The second key business with industrial customers is about supply, set-up and implementation of electric control panels of various sizes, including sensor and transducer equipment.

Other sectors such as leisure oriented places, recreation parks and hotels trust us concerning proactive maintenance of dewatering installations, repairs and replacement.

And all of the sectors we serve value our assistance in engineering, planning and implementation of complex electrical a mechanical equipment. We offer turn-key project processing from initial counseling on the phone up to the final sheet of the documentation.

E.E: What’s the news for 2020 about new products?

Wolfgang Krajewski: Our new product NEP® Generation 3 is a compact multi-machine controller for first installation or upgrade purpose. It features a detachable multilingual clear text display that enables in-door-installation. This way, it can be set up and operated easily by soft key button, even with cabinet doors closed. Connectivity by RJ45-cable or WiFi adds to its ease of operation.

The NEP® is not necessarily a pump controller only: free text entries and adjustable scaling allow for a variety of applications. The device reads all typical passive and active sensor signals (V, mA) and converts signals into clear text readings. A typical extra for waste water pumping is an integrated pressure transducer for connection of pneumatic sensors – this meaningful extra sets the NEP® apart from the competition.

The UDA® is a universal data display which shows up to 8 relevant machine data values (e.g. Amperes, operating hours, impulse counter, filling height, etc.) in one device. This way, the typical „armada“ of gauges and displays in cabinet doors can be cut down to a necessary minimum. The UDA® can come as a single function gauge or with several combinations up to the full range of 8 functions.

The multilingual clear text display makes it easy to set up an operate. It fits standard instrument cut-outs in panel doors, logs operating data on SD card, dispatches alarm messages to multiple destinations, etc.

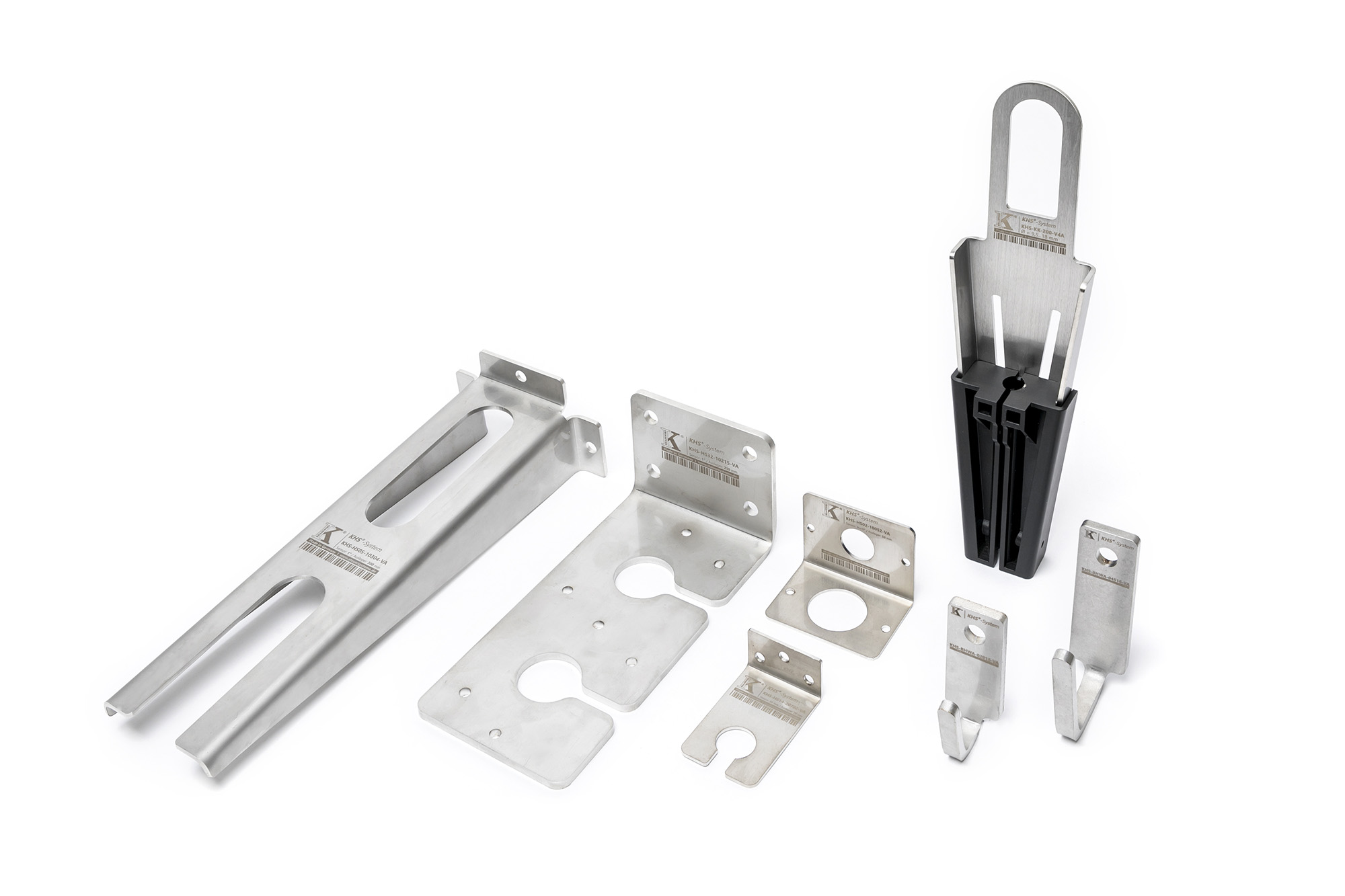

Our range of cable holding equipment KHS® involves a variety of stainless steel cable clamps and retainers, sensor holders, hooks etc. We offer a high quality, yet inexpensive alternative to OEM material. The user just needs to name machine type and required dimensions and material type, and we will deliver at short notice.

The KHS® range features accessories for most sensors, cable glands, rope and chain sizes as well as a wide range of cable diameters:

- Choice of sizes plus tailor-made fabrication on request

- Stainless steel 1.4571 / AISI 316 Ti is resistant to many civil and industrial waste water contamination

- Product examples:

- Cable clamp KHS: five sizes to hang cables from 5.5 to 41 mm ø without strain for the material

- Sensor holders HS: secure attachment and height adjustment of the sensor, keeping the right distance from wall and medium

- Utility hooks HK/BHW: heavy duty hooks to securely stow surplus cable, rope or to keep equipment from slipping and falling.

E.E: What are the ranges of traded products?

Wolfgang Krajewski: Product and service range

We provide service, maintenance and repair of most types of rotating electric machinery as well as pipe- and structural metal constructions. Our electronics department plans and produces individual electric cabinets for individual applications and automation purposes as well as compact controllers, displays, sensors and power components.

As a special service and in order to reduce delivery times, we also offer mechanical finishing of control cabinets – either as a part of our own range of complete control cabinets, or as outsourced labor for customers with their own fabrication of control cabinets.

Our technical services involve engineering and construction of electrical and mechanical installations – all steps from planning, engineering, implementation, documentation and service are done by our own experienced personnel.

E.E: At what stage is the market where you are currently active? / What can you tell us about market trends?

Wolfgang Krajewski: Processing industry: still resilient, but suffering from high prices and long lead times – projections are hard to make as decision makers are wary and hold investment decisions longer than usual.

Civil engineering, road constructions: current and new projects are constantly coming, interesting small and larger projects are in the order books or tendered with good probability of success.

Civil sector: currently satisfying order backlog and chances, but scarcer funding is already slowing the sector down and will lead to an investment bottleneck. Quantity and quality of public tenders are dropping, with fewer companies participating.

E.E: What are the most innovative products marketed?

Wolfgang Krajewski: The NEP® – our compact multi-machine controller in one small top-hat rail box, featuring a large variety of options regarding control, display, data logging and communication. Many well-known and favored functions stuffed in one small device, combined with high level of individual setup options, auto-update function, nearly intuitive quick start option and a state-of-the-art, clear text display.

Our UDA® provides up to eight different machine status displays in one device, which saves space, installation room and sources of error – for a clean and tidy control panel door, yet involving maximal control with doors closed. Extra benefits: all data logged on SD card, several communication paths for set-up and alarm, interaction with other UDA devices possible.

E.E: What estimations do you have for 2021?

Wolfgang Krajewski: We see a moderate growth in the civil sector, with focus on larger infrastructural projects. Smaller sized regional projects may be held longer than usual, small local business will be cut to necessary repairs – an investment bottleneck should be expected.

Processing industry is rather stagnating, holding investments to wait for „better times to come“, repairs and maintenance are typically still carried out as required. Long-term projections are currently not relieable.

In general, we expect „our area“ of the economy to stay resilient to the current economic and political, domestic and international situation, but external influence will influence growth prospects negatively – especially because of the influence on the supply side of the workflow.

Please contact us for more details or for distribution of info material:

Wolfgang Krajewski GmbH & Co. KG

Elso-Kloever-Strasse 2, 21337 Lueneburg, Germany

Contact person: Mr. André Meyer

Phone: +49 4131 9526 363

Email: andre.meyer@k-ug.de