ZentinelMDS (Machine Data Solutions) works with manufacturers and solution providers to develop digital observability* solutions for industrial equipment and processes.

*Observability is the ability to measure and analyze the operation of machines by examining its outputs, typically sensor data.

Easy Engineering: What are the main areas of activity of the company?

ZentinelMDS: A key area of activity is the development of custom observability solutions for manufacturing end users and machine builders.

These Obsrv! solutions are independent of the machine’s control system, using sensors to acquire the key signals required to observe the operation of the machine.

ZentinelMDS also sells and supports the products from Perinet and iNDTact for solution providers that develop their own applications.

E.E: What’s the news about new products?

ZentinelMDS: ZentinelMDS is Premium Reseller of Perinet GmbH, a German company that develops technology for direct connection of sensors to information systems based of the new Single Pair Ethernet networking standard.

We are also Value Added Resellers of iNDTact, a German company that develop advanced sensors for condition monitoring of equipment.

E.E: What are the ranges of products?

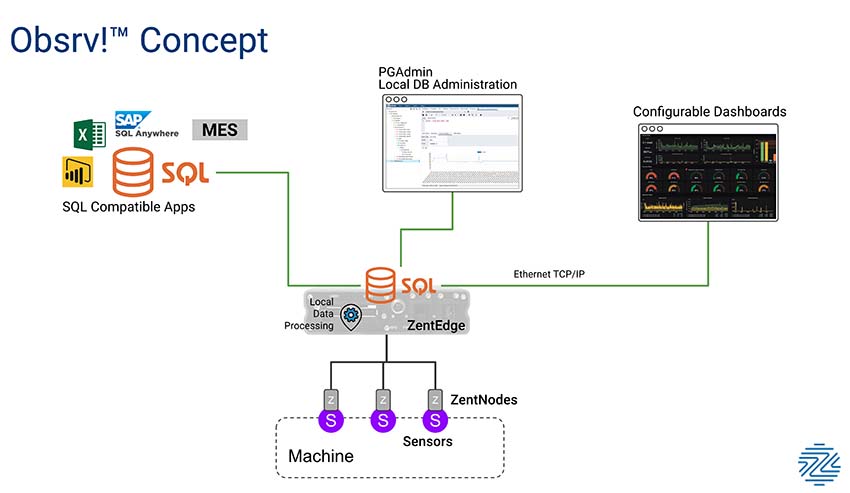

ZentinelMDS: The Obsrv! solutions by ZentinelMDS use Single Pair Ethernet and Perinet Smart Components to acquire machine sensor data, store it in SQL databases and provide tools for its analysis.

Obsrv! solutions are highly scalable.

Manufacturers and machine builders can start by acquiring data from a single sensor and easily add more data points as their observability needs evolve.

E.E: What can you tell us about market trends?

ZentinelMDS: Observability solutions for industrial equipment is a new, emerging market.

Traditional industrial monitoring solutions based on SCADA systems rely on gathering large amounts of data from the machine automation systems. These solutions are complex and expensive, require high network bandwidth and powerful computing systems, and are typically out of reach for many manufacturers.

Gathering a few data points from external sensors to observe the machine operation is a new, practical and cost-effective approach, enabled by the recent evolution in industrial networking and computing technologies like Single Pair Ethernet of the periCORE chips embedded in Perinet Smart Components.

E.E: What are the most innovative products marketed?

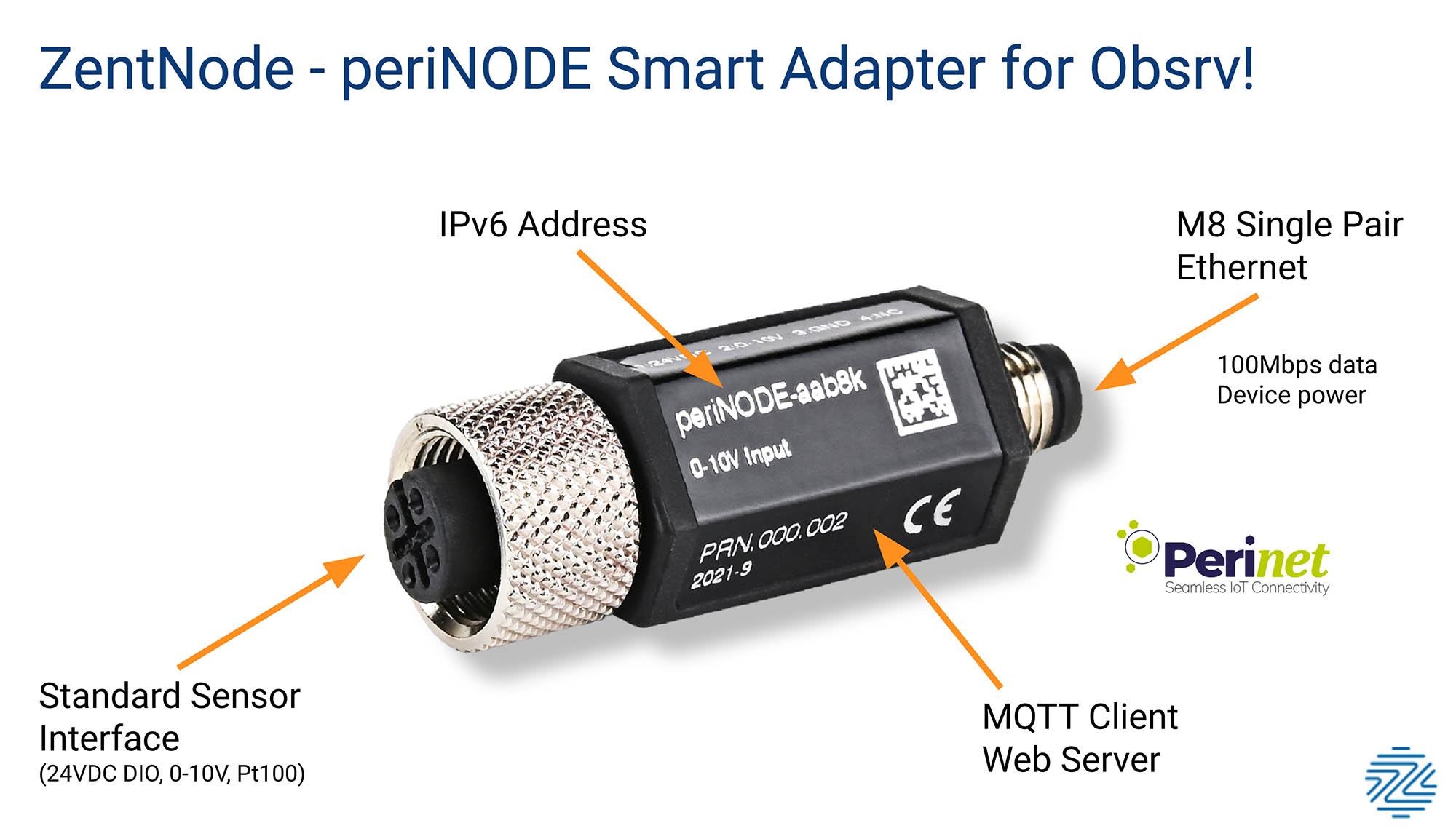

ZentinelMDS: The periNODE Smart Adapters from Perinet GmbH convert the signals from standard discrete and analog sensors into digital data that is directly available to information systems using standard IT protocols like MQTT or HTML over the Single Pair Ethernet network.

Each periNODE has its own IPv6 address, assigned at the factory, and features an MQTT client and web server for collecting the sensor data.

E.E: What estimations do you have for 2023?

ZentinelMDS: ZentinelMDS was founded in mid-2022. At this stage in our business, we’re raising awareness of the Single Pair Ethernet technology and the industrial observability concept, building interest in end users and OEMs.

We are developing a network of Solution Provider partners for the Perinet and iNDTact products working

And we are working with large consulting firms that are interested in bringing innovative Sensor2Cloud solutions to their customers.