Avery Dennison is a global materials science and manufacturing company specializing in the design and manufacture of a wide variety of labeling and functional materials. The company’s products, which are used in nearly every major industry, include pressure-sensitive materials for labels and graphic applications; tapes and other bonding solutions for industrial, medical and retail applications; tags, labels and embellishments for apparel; and radio-frequency identification (RFID) solutions serving retail apparel and other markets.

Avery Dennison is structured into 3 business segments: Label and Graphic Materials (LGM) , Retail Branding and Information Solutions (RBIS), and Industrial and Healthcare Materials (IHM).

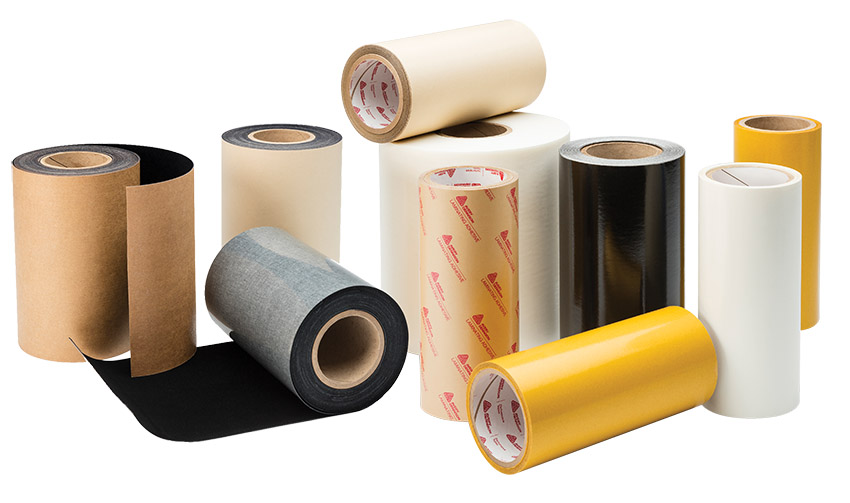

Performance Tapes

Performance Tapes is part of IHM and specializes in the development and production of high-quality pressure sensitive adhesives and tapes for a wide range of applications in the automotive, appliance, electronics, building and construction, general industrial and personal care segments. Our top-of-class expertise and global scale enable us to deliver innovative, sustainable, and intelligent solutions to customers around the world.

Product Portfolio

We are proud of our wide adhesive technology base, being able to offer customers the optimal solution from technologies spanning natural and synthetic rubber, UV cured, dispersion and solvent acrylics and silicones.

These adhesive technologies are used for a wide range of tape constructions, from simple transfer tapes through various single and double coated tapes with scrim, non-woven, foam or film carriers to specialized constructions that for example have different adhesives on each side to bound very dissimilar materials.

As Avery Dennison is also a major developer and supplier of pressure-sensitive adhesives, we have access to innovative bonding platforms such as in our HPA™ High Performance Acrylic range of transfer and double coated tapes, that are engineered for high holding power under stress and load, even at elevated temperatures.

Performance Tapes has also developed a competence in designing these PSA products to deliver vibration damping performance. Applied in various noise reduction applications, we have optimized the visco-elastic nature of these adhesives to deliver tailored damping performance requested by automotive customers.

Product Innovations

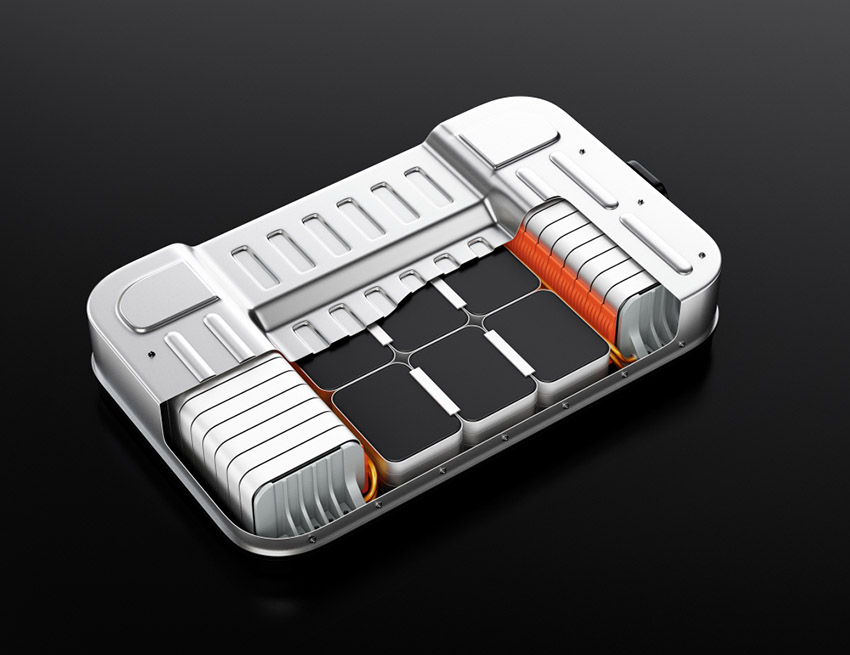

Electrification in automotive engineering is bringing with it an expanding need for PSA solutions to assemble and protect the components in the electric vehicle battery. Single and double coated film tapes protect components from short circuiting by delivering the specified dielectric strength. Flame retardant characteristics enable thermal runaway materials to be assembled in confidence. And transfer tapes bonded to foams and sealing materials enable the protection of the more fragile components.

PSA tapes also deliver on productivity in battery assembling operations; their instant tack and no requirement for additional curing means minimum delay in assembly processes. Where assembly lines have to deliver hundreds of thousands of batteries packs the cycle time is critical for productivity.

Innovation is not only found in automotive engineering. Avery Dennison also has expertise in functional films and coatings, which Performance Tapes has leveraged to produce self-adhesive vapor barrier tapes for highly insulating glazing units. With energy efficiency being critical to slow global warming, the use of these warm edge spacers prevents the insulating gas captured in double- (or triple-) glazed units from escaping and reducing their insulating efficiency.

Market Trends

With such a wide range of solutions, Performance Tapes is delivering to customers in many market segments and we respond quickly to what our customers need.

During the COVID 19 pandemic many of our customers sought to keep their production facilities active by producing Personal Protective Equipment (PPE). They came to Performance Tapes looking for advice on which PSA solution to use for their PPE, from simple masks to complete face visors. Whether bonding nonwovens, aluminum nose clips or foam strips, we had a suitable solution to enable them to produce PPE and contribute to protecting the health of the general public.

Sustainability from suppliers is an increasing demand from our customers and markets. Avery Dennison’s commitment to sustainability is enshrined in our strategic goals. As part of this, Avery Dennison launched the AD Circular program to recycle liner waste from our customers, thus reducing potential landfill. AD Circular is a new program for recycling used paper and filmic liners in countries across Europe and in the United Kingdom. Simple and cost effective, users can just sign up and have their liner waste picked up for recycling by our selected recycling partners. This scheme is open to all users, not just our customers.

At Performance Tapes we are also working on sustainable initiatives. We are working hard to have all our paper liners FSC certified this year. Since 2017 our windmill has generated one third of the energy used in the production of PSA tapes at our Turnhout, Belgium plant and we are now investing in a concentrated solar thermal plant to heat our ovens, in what will be the largest parabolic mirror installation in an industrial setting in Europe.

Estimations for 2022

The market for specialized PSA tapes continues to grow at mid single digit growth rates, driven by organic growth but also by new applications.

These new applications for example are coming from the electrification of the automotive and indeed transportation industry as well as the increased energy efficiency in buildings being driven by the EU’s European Green Deal.

PSA solutions have become a key element in the design and assembly of electric vehicle batteries, which is increasing their consumption. Electrification has also brought a greater focus on passenger comfort and thus the increasing volumes of acoustical materials is also driving more applications where PSA tapes are a popular bonding solution.

Improved insulation of public buildings and private dwellings is increasing demand for sealed glazing units and insulation materials, where again PSA tapes are a key component.

On the downside, continued supply issues and associated increase in raw material costs as well as the costs of energy and freight continues to be a challenge for the industry.

Author: Andrew Christie, Automotive Market Segment Manager for Avery Dennison Performance Tapes Europe.

LinkedIn profile

Avery Dennison Performance Tapes and on LinkedIn

Avery Dennison Corporate on Social Media

Facebook: https://www.facebook.com/AveryDennisonCorporation/

Twitter: https://twitter.com/AveryDennison