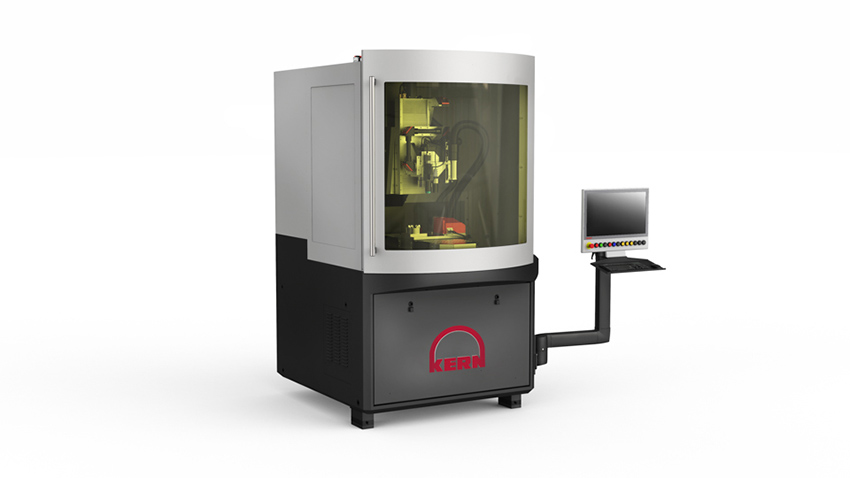

At the AMB 2022, Kern is presenting two machines – both are characterized by the highest precision on the workpiece, but which are based on two completely different technologies. Where? In Hall 7 Booth B71. What? The latest generation of the five-axis machining center Kern Micro HD and the modern laser machining center Kern Femto E3.

Producing parts in serial production with a reliable process and highest accuracies in the µm-range requires machines like Kern Microtechnik GmbH provides. These can be experienced live at the AMB 2022 in Stuttgart from September 13 to 17, 2022. With the Micro HD and the Femto E3, Kern Microtechnik is showing visitors two innovative machining centers in action, which are similar in terms of color and are characterized by the highest level of precision but differ significantly in the technology used.

On the Kern Micro HD, Kern is machining form inserts for filter housings that are milled and ground in one setting. This means that the parts are first machined and then brought to the highest surface quality at individual points using jig grinding with five-axis cycles. As a result, the parts achieve a precision of less than 1 µm and surface qualities in the single-digit nanometer range on various contact surfaces. The usual manual polishing is no longer necessary.

Also live: The production of sintered carbide press dies. The new Kern Femto E3 laser machining center has proven to be the ideal manufacturing solution for these and similar parts. The machine uses an ultra-short pulse laser to process hard materials with the highest dimensional accuracy of +/-3 µm and without heat input. Since the laser is not subject to wear, there are no tool costs. With surface qualities of up to Ra=0.2 µm, the new Kern technology is highly productive and extremely stable. Compared to EDM‘ing the time of production can be cut by 75%.

The Kern booth is also interesting for visitors who are interested in texturing surfaces. Because the Femto E3 can also do this job quickly and easily on a wide variety of materials.

Kern Microtechnik GmbH, Eschenlohe, Germany employs 240 people and operates successfully in more than 30 countries worldwide. The focus is on two business areas: The development and manufacturing of high-precision machining centers and the contract manufacturing of milled parts in the micro and nano range.

Milling centers from Kern are also used in Kern’s shop. This enables Kern to not only manufacture high-precision machines, but also to support their customers with the necessary process know-how. Customers become technology partners and are a part of the “Kern family”. Advice for ideal operation and process integration are always included – from an idea to the finished part. This enables Kern customers to increase their profit and competitiveness.

The product portfolio of contract manufacturing includes prototype, single part and series production as well as mounting assemblies and support in the construction phase. The parts are machined by milling, drilling, EDMing and grinding.