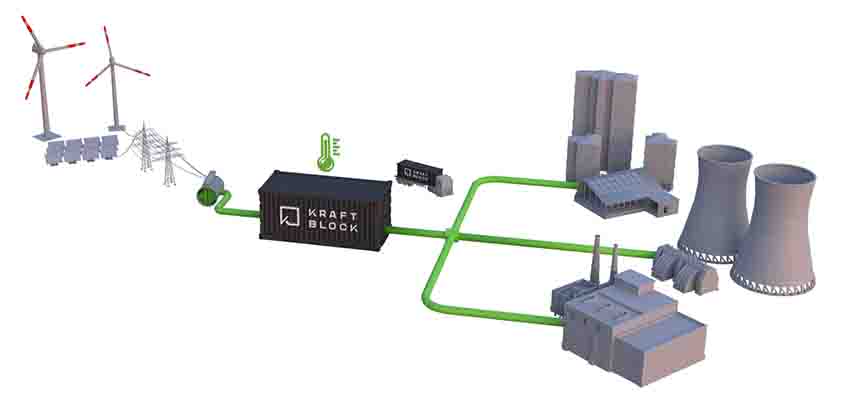

Kraftblock is an engineering and manufacturing company that builds systems to decarbonize heat in industry, district heating and power generation. At the heart of its technology is a unique proprietary thermal energy storage system using a newly invented sustainable material that can withstand temperatures of 1,300°C.

Easy Engineering: What are the main areas of activity of the company?

The German scale-up supports the transition of the entire industrial and energy sector. This can be the process heat in a food, chemicals, paper or steel factory, the district heating of cities and regions or the retrofitting of fossil fired power plants with green heat. With the Net-Zero Heat System electrification and storage is replacing fossil fuels to generate heat for water, steam, thermal oil or hot air. The Waste Heat Recycling System serves heavy industries like steel, glass, cement and ceramics to reutilize high-temperature waste heat such as excess gases from kilns or flare gas.

E.E: What’s the news about new products?

At the moment they are building a unique system at a PepsiCo factory in the Netherlands. Here, Lay’s crisps are made for eight European countries. Kraftblock replaces a 25MW gas boiler with a 22MW Net-Zero Heat System. Included is the world’s largest commercial high-temperature energy storage with about 150MWh storage capacity. The system charges electricity from the grid when it is cheap and green energy available and converts it to heat. By installing two modules in a first step with three additional models planned, a flexible operation is enabled to supply the 24/7 process of PepsiCo from the Kraftblock system.

E.E: What are the ranges of products?

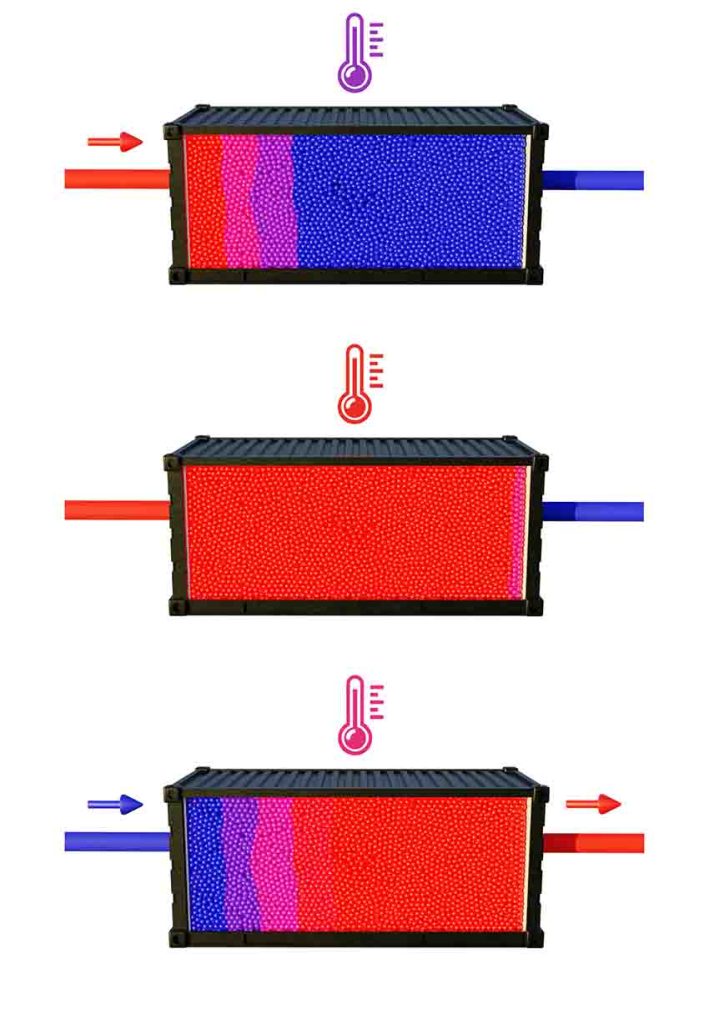

Kraftblock collects and reuses waste heat, converts electricity into heat and stores it, and connects the heat to every possible application, from heating thermal oil in industry to producing steam for power generation. While using standardized parts, Kraftblock systems are customized to integrate flexible operation and specific needs as well as power and storage capacity. In this way, Kraftblock systems can be adapted to any factory.

E.E: What is the state of the market where you are currently active?

The energy storage market in general is growing extremely fast, especially for battery storage. In comparison, the thermal energy storage market is just getting off the ground, but has a huge market potential due to the large amounts of process heat in the industrial and energy sector. Because thermal energy storage is more flexible, cheaper and more efficient than batteries and hydrogen, it is the first choice for thermal processes. In contrast to batteries, they are also designed for long duration energy storage. In Kraftblock’s case, the storage time ranges from a few minutes to two weeks, providing solutions to availability and security issues.

E.E: What can you tell us about market trends?

As industries and utilities realize that hydrogen will not solve everything, they are looking more closely at other solutions and are already implementing high-temperature thermal energy storage. With the growing share of renewables and the need for decarbonization, energy storage is becoming more and more necessary, both for the power grid and for electrifying industry and improving energy efficiency.

E.E: What are the most innovative products marketed?

The scope of research and development in the energy storage market is enormous. The products on the market are, of course, batteries, which are currently being scaled up. High temperature thermal energy storage is at the forefront of innovation as it solves several problems and is the most cost effective than batteries for heat or hydrogen for power in general. Heat pumps are also getting bigger and are being researched for higher temperatures. So there are a lot of exciting things to implement and watch for in the heat and energy storage market.

E.E: What estimations do you have for the beginning of 2024?

With only a dozen players in the high-temperature energy storage market, hard numbers are always difficult to project. In addition, the plant construction business is not a quarter-by-quarter business, but a year-by-year business, as plant construction projects typically take more than a year to build. In general, however, the trend is expected to grow exponentially in the coming years.

For Kraftblock specifically, there are some big projects happening in 2024: The PepsiCo facility is under construction, a waste heat recovery storage facility at a major steel mill is about to be built, and a project to utilize the heat from flare gases in the steel industry is expected to be completed in the middle of the year.

For the energy storage market in general, the trend of the last few years will continue and the use of batteries will increase in both the residential and utility sectors.