The company LANG, founded in 1972 at Hüttenberg, with 75 employees and managing director Thomas Kozian, represents a world-wide successful company in the field of machine tool manufacturing. Besides the CNC engraving and milling machines, laser engraving machines, the digitizing and positioning systems, as well as CAD/CAM software are the products which are developed, produced and world-wide successfully sold by the company’s own.

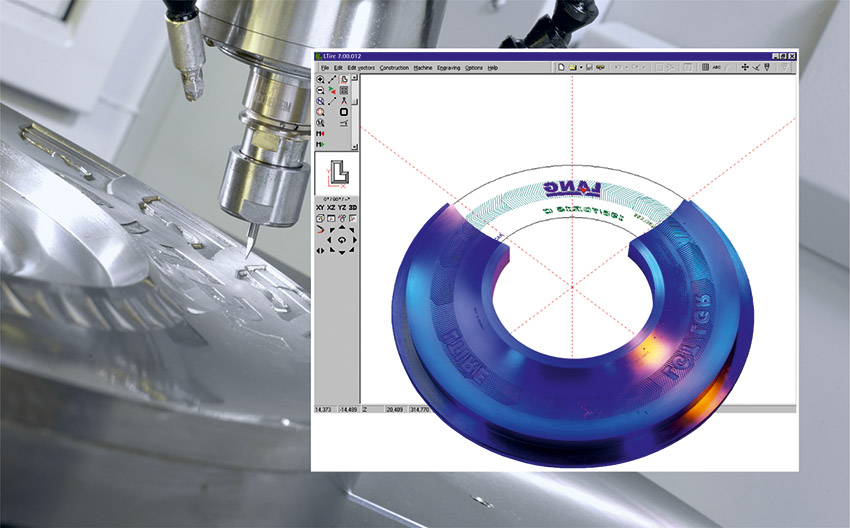

The main competence of LANG is based on the ability to offer the customer complete system solutions for his requirements. Beginning with the digitizing system LDIGIT, followed by the CAD/CAM software LErgoCAD and Reliefdesigner up to the machines, with those the generated data are output. With LANG you have only one partner for your idea up to the finished products who is competent on your side.

As a service-oriented company, the first consultation marks the start of a sequence of actions broken down into prototype production, individual customizations and own production and tests. We also guarantee first-class service after commissioning, both for all machines that leave our premises as well as for positioning controller applications in mechanical and plant engineering, laboratory automation or microscopy. Short downtimes are essential for our customers. As a result, we naturally provide rapid online support and on-site service.

Easy Engineering: What are the main areas of activity of the company?

LANG: We are both system suppliers and providers of individual solutions for companies in the areas of printing and packaging, tire molds, coin minting and security paper, toys, and the entire tool and mold making industry. We provide our customers with complete solutions consisting of machine, software, training, service and control – all from one source.

In this way and with long-standing regional supply relationships, we guarantee short delivery times and smooth order processing. The individual requirements, needs and challenges of our customers are always our top priority. Therefore, the work of our 80 employees is characterized by reliability, absolute customer orientation and trust.

Easy Engineering: What’s the news for 2020 about new products?

LANG: Targeted market observation and scientific research into consumer behaviour form part of our developments. We adapt our machines to the prevailing and future market requirements, as well as our customers’ requirements.

For example, we have been revolutionising mechanical engineering since 1990 with the development of the IMPALA series. Currently our development team is working on a new edition of the Impala 800S, a professional machine for the tool and mold making industry. The intention is to combine a modern machine design with clever use of working space for high precision engraving jobs.

In parallel, development in control engineering is running at full speed. A new servo motor series, which is characterized by low moment of inertia, compact design, high dynamics and reliability combined with smooth running, is now available for our customers.

Last but not least, our software team is currently implementing the simultaneous function of our CAD and design programs. This will result in significant progress and time savings in machine operation.

Easy Engineering: What can you tell us about market trends?

LANG: The industry worldwide is facing growing challenges such as rising raw material prices, the demand for sustainable materials and the shortest possible delivery times – and intelligent equipment and networked systems should help to meet these challenges. Our versatile product range helps industrial companies to (re)act quickly, flexibly and efficiently in line with the fourth industrial revolution.

Easy Engineering: What estimations do you have for 2020?

LANG: It is difficult to estimate this at the moment due to the current situation with Corona. Just like everyone in the international industry, we do not know how other countries will behave in the future. Surely many things will change.

At the moment, the advanced digitalization in the company is proven to be a great advantage. It allows us to make steady progress even in times of pandemics. In general, the German mechanical engineering industry offers an internationally unique broad product range with very high quality standards. This will continue to be a plus on the world market in the future.

In the meantime, we are using the time to continue our machine development and to revise our portfolio. This is a challenging time for everyone.