LiNX I AS has developed the Next Generation of mechanically attached fittings: A cold-press pipe connecting solution that creates a permanent all-metal joint, replacing welding. Inspired by the need and the potential in the market we, as a team from different parts of the globe, have come together forming LiNX | AS. Significant investment in Research and Development has produced a fully Tested and Certified initial product range of Fittings and Tooling.

LiNX|AS Fittings: Principal Elements

Development Principles

LiNX|AS fittings for connecting pipes have been developed for use in a series of demanding applications across a range of different industry sectors. The primary design features of these fittings allow their use in situations where one or more of the following attributes are important:

- Fluids at High Pressure, flammable fluids or gas, steam, etc.

- Resistance to External Fire

- Cold Process Installation

- Fit and Forget – Maintenance Free

- High Durability and Longevity

As a weld replacement, a LiNX|AS joint should be expected to last as long as the pipe, perform to the same level and to deliver this safely with significantly reduced installation time. The LiNX|AS fittings are designed to reduce the reliance, for joint quality, on the fitters and inspectors on site and to transfer this into the careful design of the joint itself, so that a correct installation is far easier to deliver, can be rapidly verified and delivers enhanced consistency with reduced variation from joint to joint.

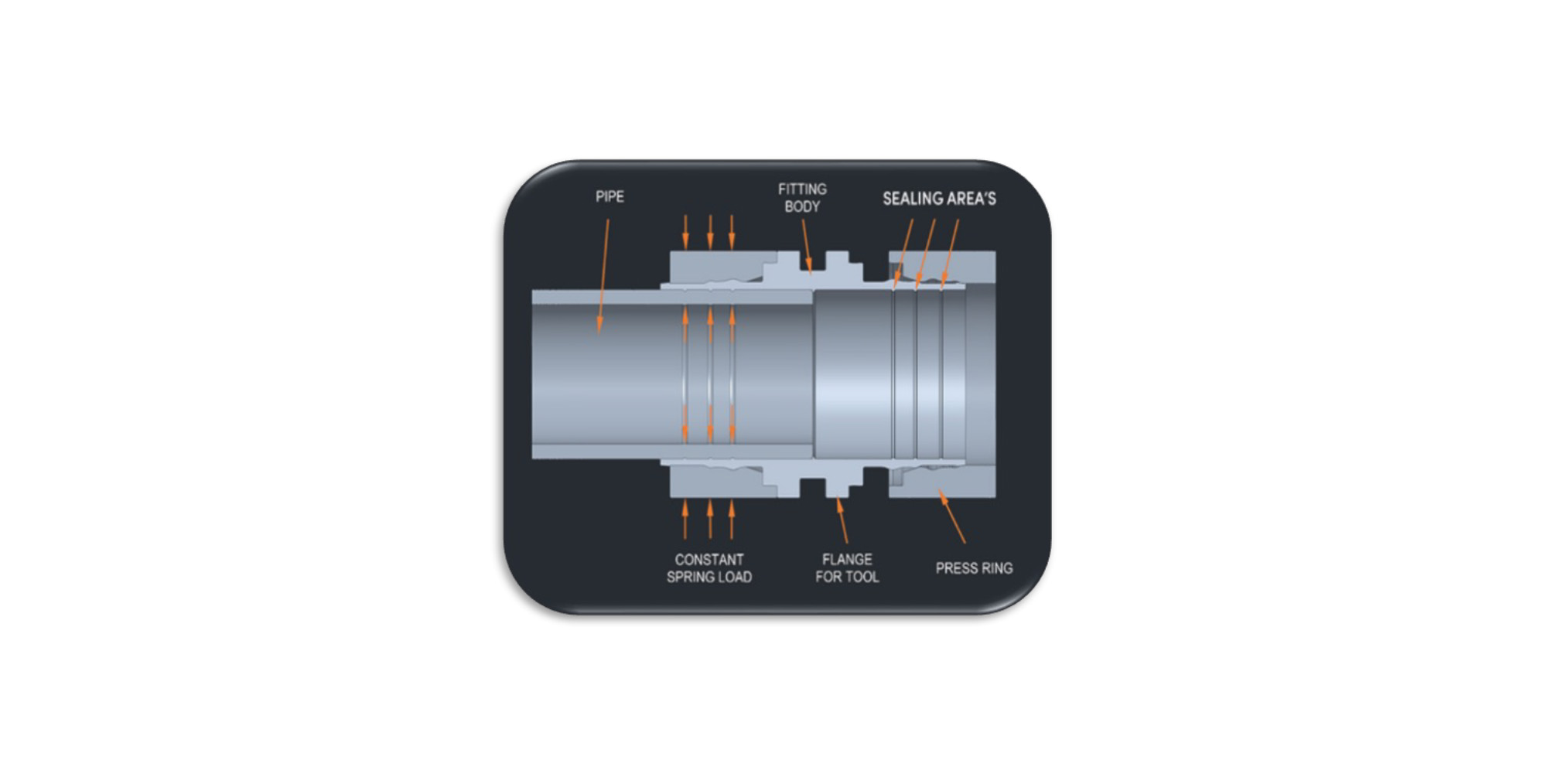

How LiNX | AS fittings work

LiNX | AS fittings are a cold-press pipe connecting solution that creates a permanent all-metal joint, replacing welding. This all-metal joint is suited to situations where Cost, Safety and Scheduling are key drivers. The technology can handle pressures up to 1400 bar, and due to their rapid, low-cost installation, LiNX | AS fittings are also advantageous for lower pressure systems.

Insert the pipe into the Fitting body, using Hydraulic tooling to advance two drive rings axially over the fitting body. Radially compressing (Swaging) the fitting body on the OD of the pipe. The pipe is compressed first elastically and then plastically during installation. The body of the fitting has circumferential machined sealing rings which grip and seal the pipe OD, forming a gas tight and metal to metal seal. Proprietary custom tooling system: Press Tool, Fitting inserts and Installation Gauge also a part of the product that performs the cold work formation of the joint.

Industries and Applications

The LiNX|AS Pipe Fitting system has numerous industrial applications worldwide as:

- Energy & Utilities

- Oil, Gas & Petro Chemical

- Chemical Processing

- Marine & Shipping

- Construction & Infrastructure

- Pharma & Foods

Advantages of LiNX | AS Technology

Simplicity

- Quick and faultless installation

- 100% Metal to metal sealing (no elastomer needed)

- Simple assembly process (single piece fitting)

- Fit and forget reliability

- Reduced installation time

Safety

- Welding/Soldering eliminated meaning no ‘hot works’

- No bonding or screws

- Only small installation space required

- Fire-Proof joint

- Boosting working efficiency

- No acid cleaning

Compatibility

- Compatible with both welded and seamless pipes

- Works on pipes with thin walls allowing the pipes to be correctly specified imperial & Metric sizes

- Suitable for Carbon, Alloy & Stainless Steels

Durability

- Improved corrosion resistance

- Higher pressure capacities

- Impervious to vibration and pulsation

- Means the pipe joints are no longer the weakest part of the system

Product Range

Sizes

Core Range : ½” to 2” (21.3-60.3 mm metric)

Full range : ¼”to 6” (13.7-168,3 mm metric, non core items are available on special order)

Materials

Standard : Carbon steel A29 4140 & Stainless steel 316L

On Request : 304 & 2205/2507

Pressure : up to 350 bar

Temperature : -33°C to 426°C

Certifications

LiNX|AS fittings are certified to the following standards:

- Lloyd’s Register

- ASTM-F1387

- ISO-9001:2015

Approval and safety testing

The tests are as per Lloyd’s register specifications and ASTM F1387 standards:

- Tightness test

- Brust test

- Pressure Pulsation test

- Pull out test

- Vibration test

- Vibration & pulsation test

Complete Mobile Stand alone Linx system

A complete LiNX system exist of:

- Fittings

- Press tool box

- Hydraulic pump on battery

Comparison between Weld Joint & LiNX | AS Fitting

| Welded Joint | LiNX | AS Fitting |

| All hydrocarbon and inflammable lines need to be isolated for hot works before welding | No hot works and no isolation required |

| Degreasing of the pipe outer (if any) needs to be done where the welding is required | Surface preparation with sandpaper is sufficient |

| Cleaning the pipe inner by purging with inert or a neutralizing chemical may be required in certain piping areas | Not Required |

| 45° Chamfering or ‘J’ preparation for Beveling of pipes required for a quality welded joint | 90° Cut and Deburr only |

| IBR certified welders are required to carry out the weld | Joint can be formed by a trained pipe fitter |

| Certain welding areas may require very high skilled 6G welder | Same fitting skill set is sufficient for any position of fitting |

| Welder will require a helper and the work will need supervision from project owner side | Work supervision not required, and the helper is optional |

| A spot weld first followed by seal weld needs to be performed for the best results | One-step sealing of fitting is sufficient |

| Post welding, the weld needs to be qualified by radiography | Visual Assessment Only: Correct locking first time, every time |

| Radiography is dangerous to humans and needs special care involving 2 persons and supervision | Not required |

| Post welding the pipe needs to be stress relived in most cases involving 2 persons | Not required |

Key Product benefits

Installation Benefits

| Highlights | Advantage | |

| User Friendly | Lloyd’s register approved | Tested and approved to meet all requirements of Lloyd’s register |

| Material choices suitable for wide range of applications | Customer can easily choose based on their application requirement needs | |

| Pipes range from ¼” to 2” | Fits perfectly with standard range of pipes | |

| Project Oriented | Applicable to high pressure systems | One fitting can be used with other lower schedules |

| No NDE Test Requirements | Service can be started immediately after visual inspection | |

| Perfect installation on first clamping itself | Cost effective Process | |

| Site Preferences | Adaptable to last minute change on site | Change can be for many reasons on site our fitting are adaptable to such changes with less disruption and cost |

| Finalising the joint alignment can be done on side | Adaptable to minor misalignment on site | |

| Orientation of fitting installation not an issue | Changing the orientation of fitting do not cause any stress in the line | |

- Faster installation compared to alternative methods

- Better performance at lower Cost

- 100% perfect and effective join on single clamping-every time

Operational Benefits

| Highlights | Advantage | |

| Performance | Designed and tested to withstand harsh circumstances | Assured quality ensures safe use in service condition without and failure |

| Safety | Service life longer than the pipe itself | Maintenance free during lifetime |

| Fire-Proof metal parts hold the joint even in fire | Suitable for use in pipelines carrying fuel and flammable fluids | |

| Uses no heat sources for joining so no fire or explosion hazard | Immediate return to service after repair | |

Contact

Representative Linx Europe / writer article G.J.Brons