MaterialsZone is a forward-thinking Lean R&D solution that has pioneered a unique AI-driven cloud-based materials informatics platform enabling Lean R&D to expedite and cost-effectively enhance the development of diverse physical products. MaterialsZone harnesses extensive materials science, data science, and software engineering expertise to provide a versatile, industry-agnostic solution serving customers across various sectors.

Interview with Dr. Assaf Anderson, Founder & CEO of MaterialsZone.

Easy Engineering: A brief description of the company and its activities.

Assaf Anderson: At MaterialsZone, our mission is empowering companies to optimize their research and manufacturing initiatives, ensuring their continued success and growth. Our pioneering efforts have not gone unnoticed, with esteemed recognition from prominent organizations and customers such as Microsoft’s AI for Good, The European Commission’s Horizon 2020, Tech For Good, Microsoft for Startups, Intel Ingenuity Partner Program, and Kafrit Industries.

E.E: What are the main areas of activity of the company?

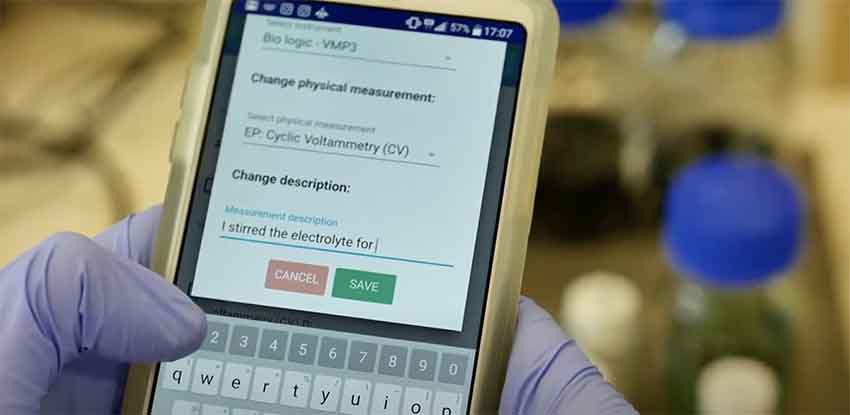

A.A: MaterialsZone facilitates and enhances the innovation and production processes of the companies we collaborate with. Our proprietary platform is a critical tool for these organizations’ research and development (R&D) teams, effectively acting as a centralized data hub with embedded AI capabilities. This multifaceted platform empowers these teams to complete the long iterative R&D process and seamlessly transition from the R&D stages to full-scale production, streamlining the entire product development lifecycle.

One key area of focus is the efficient progression from concept to market-ready product. MaterialsZone’s platform is tailored to expedite this transition, quickly transforming innovative ideas into tangible, physical products. Our AI-driven approach plays a pivotal role in optimizing these transitions, enabling companies to reduce time-to-market and, ultimately, increase their competitive edge in the market.

Another significant aspect of our activity lies in sustainability and waste reduction. The platform’s data aggregation capabilities and AI-driven insights help companies make informed decisions regarding replacing materials that don’t meet the sustainability standards with new materials selection that do and reducing the amount of chemical waste and emissions created during R&D experimentations. This allows for waste reduction, and the platform provides guidance so R&D personnel can make the right adjustments to the products that go to production with a smarter selection of the ingredients and processes. Thiscontributes to a more sustainable and environmentally responsible approach to product development, aligning with global initiatives for eco-conscious practices.

In summary, the main areas of activity for MaterialsZone encompass driving innovation, efficiency, and sustainability in the product development process. Our platform empowers R&D teams to harness the potential of advanced materials informatics and AI, leading to faster, more eco-friendly, and economically sound production practices across diverse industries.

E.E: What are the ranges of products?

A.A: MaterialsZone is an industry-agnostic SaaS platform with several functionalities divided into packages and gives R&D teams the capabilities to innovate and optimize their processes. This innovative platform delivers comprehensive capabilities catering to diverse industries and sectors.

At its core, MaterialsZone is a secure data management hub, allowing organizations to centralize their data within a secured cloud environment, accessible from anywhere. This hub facilitates team collaboration, laying the foundation for analytics and AI applications.

Instant analytics is another pivotal feature, providing valuable insights derived from the data stored in the hub. Through visualizations, statistics, graphs, and a range of analytical tools, researchers gain the means to make informed decisions swiftly.

Beyond analytics, MaterialsZone incorporates AI and predictive capabilities. These capabilities enable predictions regarding virtual (non-existing) concepts, accelerating the innovation process by focusing on areas of genuine significance.

In delivering an all-encompassing solution, MaterialsZone simplifies the selection process for its clients, ensuring adaptability and relevance across different industries. The platform’s singular focus on versatility embodies MaterialsZone’s unwavering commitment to making cutting-edge materials informatics and AI-driven innovations accessible and advantageous for various companies, irrespective of their area of expertise.

E.E: At what stage is the market where you are currently active?

A.A: MaterialsZone is operating in the digitally transformative phase of the market to Lean R&D, being this is a fairly new concept to the development and manufacturing of materials and materials-driven products. During this phase, the platform educates them on its impact on their research and development processes. It progressively introduces manufacturing professionals to its capabilities to drive a more effective end-to-end process.

In this stage, MaterialsZone aims to convey its value to materials-driven manufacturers, ensuring they grasp how the platform addresses their specific needs in the manufacturing industry. This gradual exposure and education are crucial for establishing enduring partnerships and driving MaterialsZone’s growth, which will sponsor the development and manufacturing sector’s growth.

E.E: What can you tell us about market trends?

A.A: Currently, MaterialsZone is the only platform on the market that bridges the gap from R&D to full-scale production. In the future, as systems become more mature and widespread, we can anticipate a convergence of various stages into a unified solution. For instance, the integration of materials informatics for research and development with monitoring systems for production. This combination enables a seamless transition from R&D to the production stage. Similarly, systems designed to optimize production yields may merge with predictive maintenance systems in the production phase, ensuring efficient operations. We can foresee an even more comprehensive integration as technology advances, where R&D, scale-up, and production phases come together in a harmonized materials informatics system.

E.E: What estimations do you have for the rest of 2024?

A.A: Materials’ R&D companies, external R&D labs, and manufacturers will continue to make the end-to-end faster and cost-effective, prioritizing supply chain optimization to counter disruptions and ensure the seamless flow of raw materials. At the same time, the digital transformation of manufacturing processes, underpinned by Industry 4.0 technologies like IoT and AI, will persist in driving enhanced efficiency and innovation.

Sustainability and the circular economy will remain in the spotlight, with manufacturers increasingly embracing eco-friendly practices and designing products with reduced environmental footprints.

Materials and manufacturing techniques, like additive manufacturing, are expected to garner greater recognition for their ability to produce intricate, lightweight, and high-performance components while minimizing material waste.

In addition, the manufacturing industry will continue grappling with the pandemic’s ongoing repercussions, solidifying recovery efforts and fortifying resilience to navigate the ever-evolving landscape. These trends collectively shape the path forward for manufacturers, where adaptability and innovation remain essential pillars of success.