Mastim offers automation and robotization of production processes through the design, construction and implementation of a customised solution. The company’s offer includes tailored solutions to improve and optimise the production processes like assembling, injection moulding, packaging, paletization etc. They help in the development or modification of technology to enable automation tailored to the nature of the work and the industry.

Mastim’s team is made up of specialists and practitioners with experience, knowledge, market expertise and, just as importantly, a passion and love for modern technology.

Interview with Sylwia Geda, Project Manager at Mastim.

Easy Engineering: What are the main areas of activity of the company?

Sylwia Geda: We design and build specialist machines and integrate robots and other manufacturers’ machines into functional and efficient production lines for a company in any sector, although we specialize in the sector plastics processing industry. We design and implement IML technology, handle the picking and stacking of moulded parts and develop side-entry robots for high speed applications. We automate quality control processes by implementing vision systems, measurement and separation. We also provide mould design services.

E.E: What’s the news about new products?

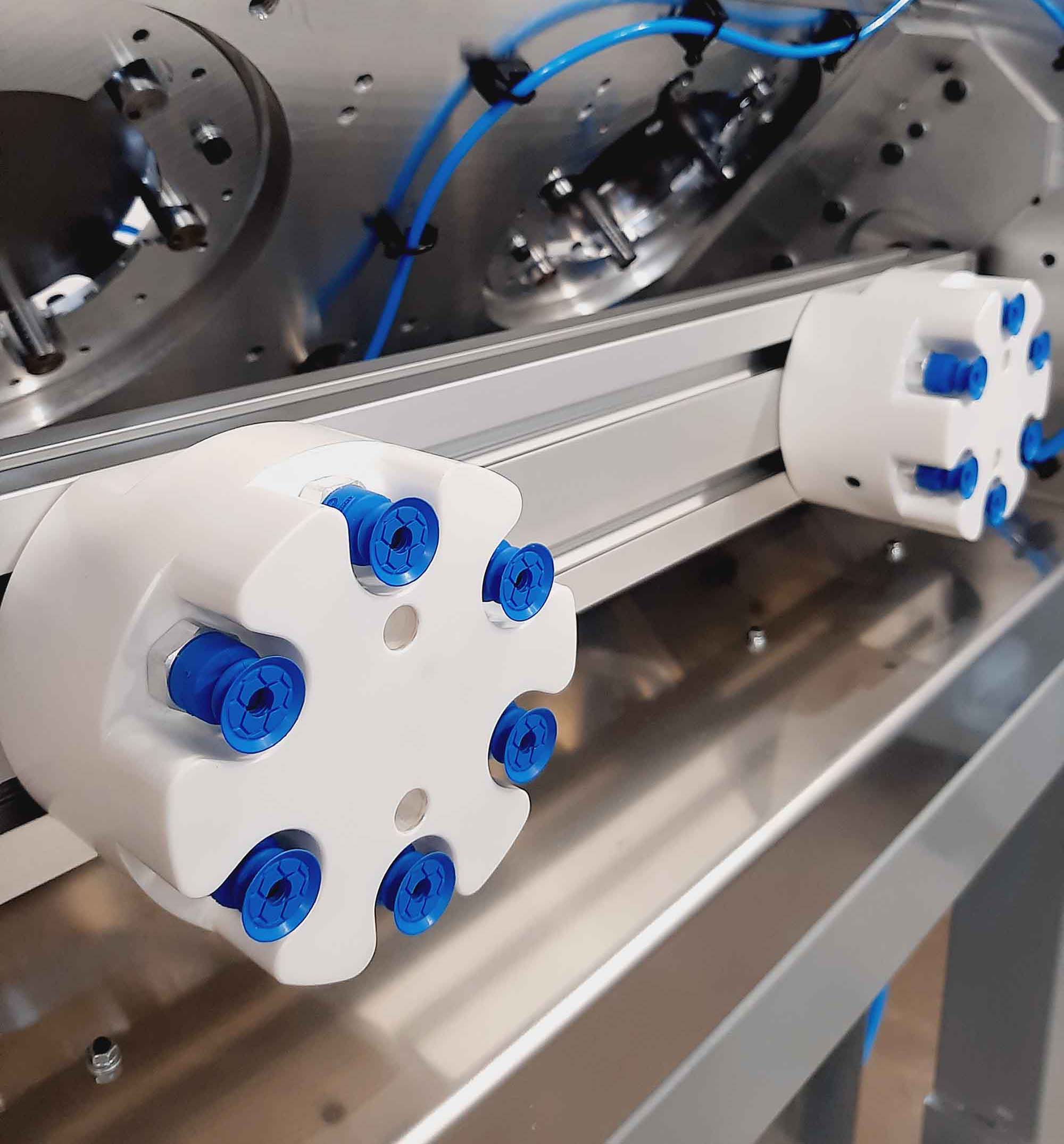

S.G: Our new product line is automation and robotics systems based on direct drives – linear and rotary. Such solutions improve the energy efficiency of our solutions by eliminating intermediate transmission systems (ball screws, belts, gears, etc.). The overall design is also more compact, saving space on the production floor. An additional benefit of linear drives is that there are far fewer intermediate mechanical components to service, maintain and replenish consumables.

E.E: What are the ranges of products?

S.G: We specialise in the design and development of high-speed solutions that operate with dynamics in excess of 30 m/s2 and motion speeds of up to 7 m/s. In such solutions, direct drives are ideal due to their high power density. Examples of applications include: side robots for handling injection moulding machines (especially in IML technologies), large delta robots, laser cutting head drives and many, many more.

E.E: At what stage is the market where you are currently active?

S.G: The market for automation and robotics is growing rapidly. Companies that want to increase productivity while maintaining the highest quality must rely on modern technology. Robotic production lines represent innovation, progress and independence that guarantee a strong position in the market, which is why more and more companies are choosing to work with technology suppliers. Increased awareness also contributes to the development of the market in which we operate. Work automation is not only about increasing productivity while minimising costs (although this is very important), but also about energy-efficient solutions, which – especially recently – have attracted the attention of entrepreneurs.

E.E: What can you tell us about market trends?

S.G: The market is very dynamic due to the increasing automation of work, but a key factor is ecology and energy efficiency. Companies expect the solutions they implement to contribute to environmental sustainability. The answer to this demand is green automation and working with technology suppliers that take a pro-environmental stance. Companies that are both technologically advanced and environmentally responsible will attract investors.

E.E: What are the most innovative products marketed?

S.G: According to the company’s philosophy, every service we provide brings innovation. However, if I had to point out the most innovative product, it would be the family of cores for IML technology, which are manufactured in an innovative way designed by MATSIM. The advantages of our lasts are lower manufacturing costs (lower price on the market) and longer life.

E.E: What estimations do you have for 2023?

S.G: The market we serve is the future of manufacturing companies, and the demand for our services is growing. The outlook is promising – more challenges and new collaborations, which is always very motivating. Nothing is more exciting than a new project, and knowing that we are ‘grafting’ modern technology into yet another company is very satisfying. We are ready to improve production processes on an ever-increasing scale. We intend to work hard to expand our customer base and strengthen our position in the technology supplier market. In the high-tech industry, there is a constant need to learn, so we are planning a number of activities to develop the skills of the team.