Since 2001, Zhuzhou Meetyou Carbide has been exceeding their goals step by step in the hardmetal industry. As one of the biggest tungsten carbide manufacturers in China, the love and passion for innovation and determination helped them to carve out a path of success.

Recognized worldwide for quality carbide blanks and carbide cutting tools for a variety of applications, beyond an extensive product line, Meetyou Carbide focuses on continuously reinforcing your productivity with an innovative approach.

Zhuzhou Meetyou Carbide is a private technology enterprise integrated with development, design, production, and marketing of cemented carbide products. Now, its total fixed assets exceed 100 million RMB, and the floor area surpasses 25,000 m².

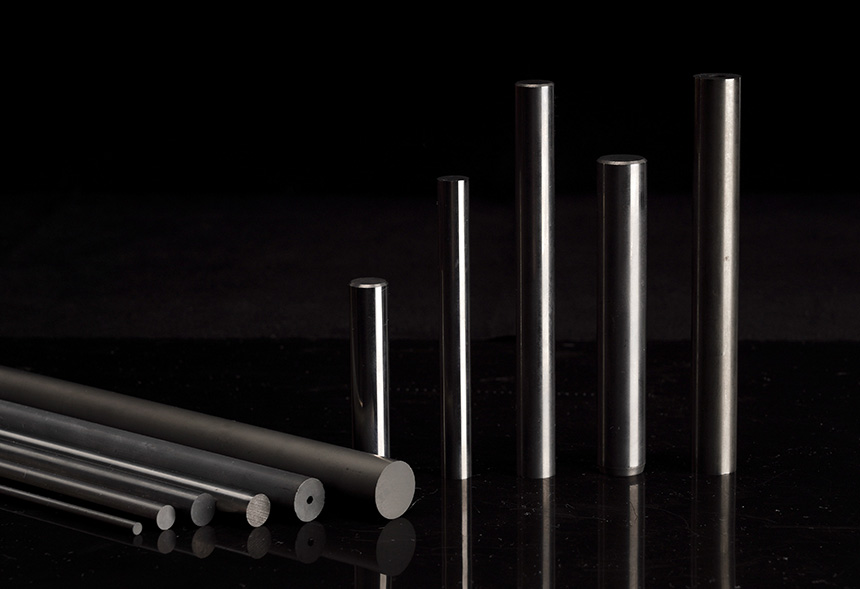

Solid cemented carbide rods are widely used for high-quality solid carbide tools such as milling cutters, end mills, drills or reamers. It can also be used for cutting, stamping and measuring tools. It is used in the paper, packaging, printing, and non-ferrous metal processing industries. Carbide rods can be used not only for cutting and drilling tools but also for input needles, various roll wore parts and structural materials. In addition, it can be used in many fields, such as machinery, chemical, petroleum, metallurgy, electronics and defence industries.

Specialized in tungsten carbide round bars, with an outstanding product line of coolant and solid carbide rod, we manufacture and stock unground and ground carbide rods for you. Our h6 polished chamfered cutting tool blanks are the most popular.

Sintering HIP

The advanced computer-controlled HIP furnaces are applied to provide more pressure during the sintering process in order to get denser structure.

Powder Excellent

Thanks to our deep cooperation with Germany H.C.Starck, we use the best powder for carbide rod in the world for all our standard grades for carbide rod manufacturing.

Fast production

Three different compaction methods, including extrusion, automatic press, and cold isostatic press are used for the maximum efficiency of carbide rod manufacturing.

Manufacturing Special Methods

Extrusion – Extrusion is the most popular method of producing carbide rods. It is a very practical way to manufacture long carbide rods like 330mm.310mm and 500mm, etc. However, its time-consuming drying process is the weakness that we have to pay attention to.

Automatic Press – Automatic pressing is the most effective ways to press short sizes like 6*50,10*75,16*100, etc. It can save cost from cutting carbide rods and it doesn’t need time to dry. So the lead time is faster than extrusion. On the other hand, long rods cannot be manufactured by this method.

Cold Isostatic Press – Cold isostatic press (CIP) is the latest technology of making carbide rods. Because it can make long bars like 400mm but it doesn’t require wax like extrusion, so it doesn’t need time to dry, either. This is the best option when making big diameters like 30mm and 40mm.

Materials H.C.Starck Powder

Our grade coverage ISO K05 to K40, from machining aluminium, steel, non-ferrous metals, to titanium or we develop grade for your applications. Our 10% cobalt grade MT10S is widely used for machining aluminium and steel or general application. Our 12% cobalt grade MT12S is specially designed for machining stainless steel and our MT25S with 0.4um grain size is meant for high hardness processing. Thanks to our deep cooperation with Germany H.C.Starck, we use the best powder for carbide rod in the world for all our standard grades for carbide rod manufacturing.

As one of the biggest Solid Carbide End Mills manufacturer in Zhuzhou, China, Meetyou Carbide produce and stock all kinds of standard end mills for steel, aluminium, stainless steel, etc. OEM and special tools are also provided.

When working in the metalwork arena, the choice of cutting materials is one of the greatest decisions you’ll face as the selections will influence everything about the final outcome.

Finding The Right Carbide End Mills

When choosing the right carbide end mills for your applications, there are several factors to consider. These include the critical angles (end cutting edge angle, axial relief angle, radial relief angle, and radial rake angle) and length and finish of the flutes.

What Is A Carbide End Mill?

In its most basic sense, a carbide end mill is a cutting tool that can be used for a wide range of industrial milling operations. It will commonly be used in lathes and similar resources used for metalwork cutting and applications.

Carbide end mills are, unsurprisingly, made from a compound of carbide and cobalt. While they may look like drill bits at a glance, they offer a far better function as they can move in all directions (unlike a standard drill bit). This makes them particularly ideal for a range of geometric cutting tasks, and are often used on aluminium.

They fit into a lathe in a straightforward fashion and offer a reliable performance even under high heat and pressure. They may be used to create a variety of grooves, slots, and pockets in the workpiece.

Why Choose Carbide End Mills?

First and foremost, the fact that an increasing number of mould shops and applications are choosing aluminium over traditional steel materials has resulted in a significant spike in popularity for carbide end mills.

Aluminium has soft properties, meaning that very specific geometries and characteristics are needed to gain reliable results. This makes carbide end mills the perfect tool for the job.

Carbide end mills ultimately save time and money. When using the correct cutting geometries and coatings, mould finishing times are significantly reduced as achieving finishes of 16µ and above becomes far easier. Likewise, metal removals can become up to five times faster.

The wide range of geometries and angles also leaves the user with immense versatility and control. From indexable end mills to helical cutting edges, those tools can be used to create a wide range of finishes.

Advantages

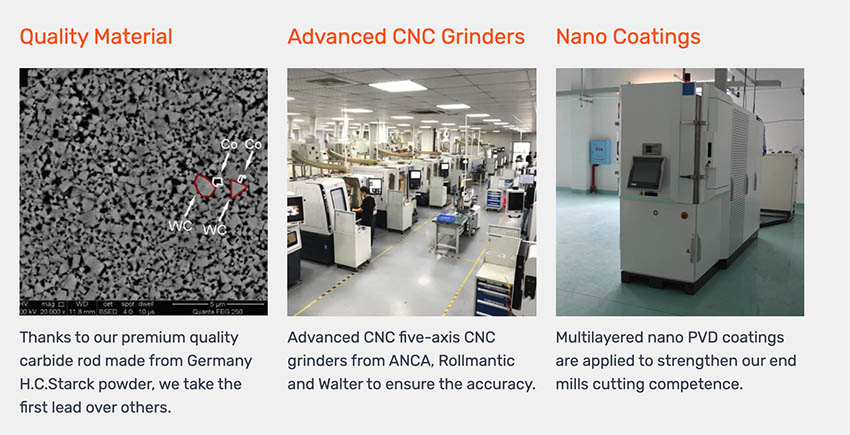

Quality Material – Thanks to our premium quality carbide rod made from Germany H.C.Starck powder, we take the first lead over others.

Advanced CNC Grinders – Advanced CNC five-axis CNC grinders from ANCA, Rollmantic and Walter to ensure the accuracy.

Nano Coatings – Multilayered nano PVD coatings are applied to strengthen our end mills cutting competence.

ZHUZHOU MEETYOU CARBIDE

Tel.: + (86) 731-28420963

Mail: sales@meetyoucarbide.com