MICOR has been a leading company in the field of infrared special machinery and plant engineering for more than 45 years. As the oldest company specializing in infrared heat in industrial processes, they‘ve been offering customized solutions for individual heating and drying processes using short-wave infrared radiation (NIR) ever since they were founded.

MICOR believes that every production process is unique, and they take pride in designing infrared systems that are tailored to the specific requirements of each customer. The company‘s team of experts works closely with customers to identify their needs and develop custom solutions that help them optimize their production processes in a sustainable way.

The company’s infrared systems are designed to improve drying performance, increase production speeds, and enhance the efficiency of heating processes. MICOR understands that customers need to produce high-quality products while minimizing energy consumption and costs, which is why they focus on optimizing both product quality and energy efficiency.

With decades of experience, MICOR continues to innovate and provide customers with the highest level of service and support.

Interview with Svenja Wettengl, Inside Sales Manager at MICOR GmbH.

Easy Engineering: What are the main areas of activity of the company?

Svenja Wettengl: Infrared heat is a versatile and sustainable solution that can be used to support a wide range of manufacturing and drying processes. At MICOR, we offer infrared heaters equipped with our proprietary *KIR technology that are specifically designed to meet the needs of highly productive industrial processes. Short-wave infrared (NIR a) is particularly effective in drying and heating materials, coatings, inks, and surfaces. Our premium quality *KIR heaters are designed to provide exceptional performance and versatility, making them an ideal solution for industrial production in a variety of sectors. Our infrared heaters can be used in the printing, paper, packaging, coating, textile, furniture, woodworking, laminate, plastics, rubber, cable, and many other industries. Whether you need to heat materials to a specific temperature, dry water-based or solvent-based inks, or cure coatings, our infrared heaters are the perfect solution. With our short-wave emitters, our customers can achieve fast and efficient production speeds while maintaining a high level of reliability.

E.E: What are the ranges of products?

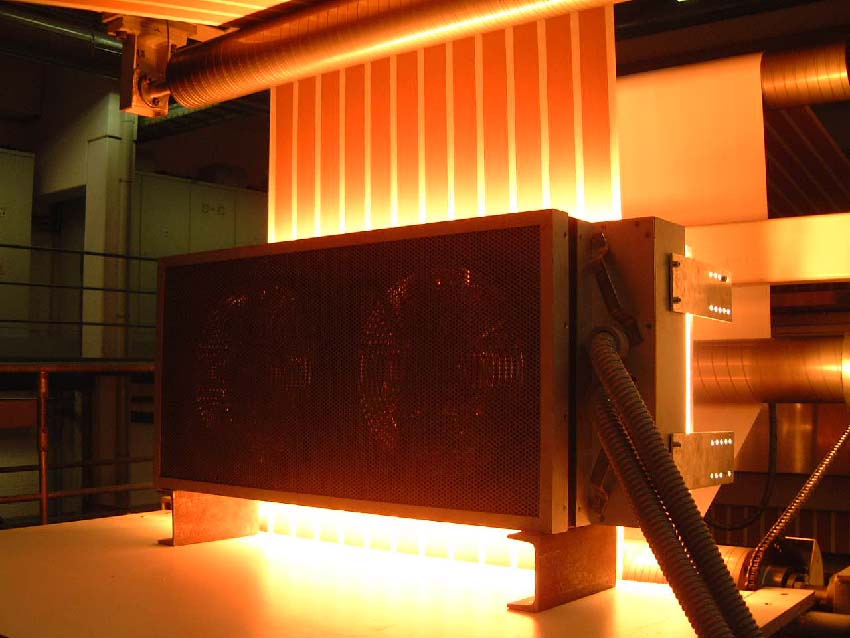

S.W: MICOR offers an innovative and diverse range of contact-free, short-wave infrared systems that can be precisely tailored to meet the individual needs of our customers. Our near infrared emitters are available in various designs such as modules, cassettes, band radiators or spots. They significantly increase the speed of drying processes and are ideal for non-contact heating of continuous webs and surfaces, as well as for edge heating or as a highly effective IR spot for pinpoint applications. Due to their flexible and modular construction our infrared systems can be integrated into existing machines. Our primary focus is on the individuality of our systems. We understand that our clients are looking for solutions that are tailored to their specific needs, which is why we take a comprehensive approach to the design and manufacturing of our products. The NIR part as well as the power control unit and the cooling are individually manufactured and optimally adjusted to the customer’s machine. This means that even existing machines can be easily retrofitted with a shortwave infrared system. By retrofitting, the machine can be optimized in an efficient and at the same time cost-effective way.

E.E: What are the most innovative products marketed?

S.W: MICOR takes pride in being a supplier that stands out from the competition. We are known for relying on fully integrated infrared systems, which allows us to achieve our customers’ goals of energy efficiency and speed optimization. One of the key features that sets MICOR apart from other suppliers is our proprietary reflector system. This reflector system is an integral part of all our emitters and is designed to maximize the use of infrared radiation. Our reflector system has a unique geometry that ensures targeted and high-energetic use of infrared radiation, resulting in an efficiency rate of up to 98%. This means that the energy consumed by the system is directed to where it is needed, which translates into significant energy savings for our clients. By incorporating our innovative reflector into our infrared systems, MICOR is able to offer solutions that combine speed increase and energy efficiency in a practical and effective way. This ensures that our customers can achieve their goals of improved machine performance and energy savings, while also benefiting from a cost-effective and sustainable solution.

E.E: What can you tell us about market trends? / What estimations do you have for 2023?

S.W: In recent years, the industrial sector has been increasingly focused on improving energy efficiency, reducing greenhouse gas emissions, and applying intelligent automation technologies in their heating and drying processes. The issue of future gas availability and the significant increase in energy costs have put immense pressure on many industries, particularly those that are energy-intensive, such as paper, steel, and printing. To overcome these challenges, it is crucial for these industries to act and optimize their heating processes.

As the need for energy-efficient solutions grows, companies are turning to innovative technology to optimize their operations. Among these technologies are electrically powered drying and heating systems, such as the infrared systems provided by MICOR. These systems are becoming increasingly crucial in the industry, as they offer the potential for the utilization of renewable energy sources, which can help to reduce dependence on fossil fuels and lower CO2 emissions. By implementing electrically powered drying systems, companies can make significant strides towards achieving their environmental targets while simultaneously improving their bottom line. Moreover, the electrification of industrial heating and drying processes offers benefits regarding improved process control and increased plant flexibility.

Svenja Wettengl, Inside Sales Manager at MICOR GmbH.

In recent years, we have also had a strong focus on research into new applications for short-wave infrared radiation. We believe that independent of pure drying and heating processes, there is great potential for the use of NIR radiation. In this context, we are cooperating with various research institutes and universities in an effort to apply our practical knowledge to innovative projects.

At MICOR, we are committed to providing our customers with cutting-edge infrared drying systems that are both energy-efficient and environmentally sustainable. We believe that the growing demand for such systems presents an opportunity for us to make a positive impact on the industry and contribute to optimizing the environmental balance. As we look towards the future, we anticipate that these trends will continue to evolve, and we remain dedicated to developing innovative solutions that meet the evolving needs of the industry.