MIRAI Intex® is a manufacturing company that has made refrigeration technologies more efficient and environmentally friendly through its developments and the use of natural refrigerants. They hold numerous patents, safeguarding our innovations globally.

Interview with Vladyslav Tsyplakov, Development Director at MIRAI Intex.

Easy Engineering: A brief description of the company and its activities.

V.T: At the heart of our operations lie the MIRAI X CRYO (closed cycle solutions) and MIRAI Cold product lines (open and closed cycle solutions).

We take pride in our status as a technological leader in ultra-low temperatures. These refrigeration systems not only use air as a refrigerant but also represent a revolution in the industry. They contribute to reducing greenhouse gas emissions, ensuring environmental sustainability, and providing high efficiency, and reliability with zero Global Warming Potential (GWP).

With MIRAI Intex air technology customers can rely on key features as:

- Eco-friendly refrigeration technology with a 0 GWP refrigerant

- Temperature flexibility ( -40°C to –160 °C)

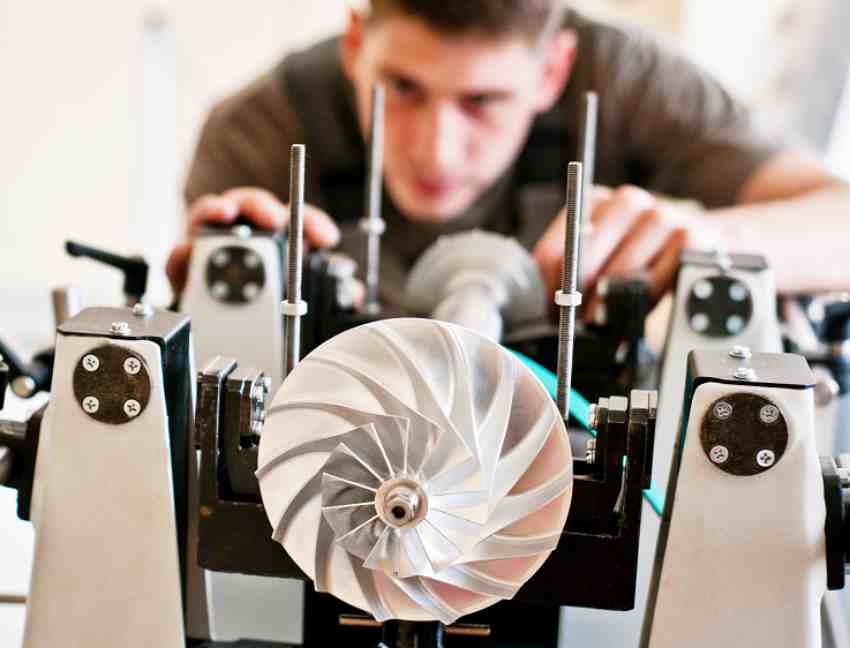

- Oil-Free Turbo compressor/ expander

- High energy efficiency

- Remote monitoring

- Minimal service requirements

E.E: What are the main areas of activity of the company?

V.T: Global Leadership in Sustainable Refrigeration Solutions

We are building a future where efficient refrigeration technologies play a key role in the sustainable development of industry and the planet. MIRAI is actively expanding its role in new markets, offering innovative solutions in the pharmaceutical, energy, technological, chemical, and food sectors.

E.E: What are the most innovative products/services marketed?

V.T: Latest product innovations and market drivers

MIRAI unveiled in February 2024 its latest innovation MIRAI X CRYO product line, providing the broadest temperature range yet, from -120°C to +50°C and promising unparalleled performance and versatility across various industries where reliable temperature consistency and temperature accuracy is needed as vacuum coating (physical vapor deposition), pharmaceutical industry and other.

Among the new products is the MIRAI XS CRYO, designed to address the specific requirements of the semiconductor manufacturing market, especially in dry etch processes of the semiconductor manufacturing, playing a strategic role in many other industries as electronics, automotive industry, health care, and medicine, industrial automation, and telecommunications.

Our standard product portfolio under the brand MIRAI Cold includes refrigeration systems for ultra-low temperatures from -110°C to -40°C with open or close air cycle systems and industry applications such as freeze drying, blood plasma freezing, food freezing, and cryotherapy.

But MIRAI also expands and presents the MIRAI LNG series, advanced refrigeration machines meticulously crafted for the liquefaction of biomethane. The largest-scale solution for bio-LNG liquefaction processes is represented by MIRAI Cold 150 LNG. This model, with its increased capacity, is ideal for meeting the demands of medium-scale BioLNG/LNG productions and reliquefication of BioLNG/LNG or there is also an option to take advantage of the modularity and connect more MIRAI LNG systems in one production station.

Quality Standards and Education:

We pay special attention to the quality of our products and services, elevating our management quality to the highest global standards, including ISO 9001:2015. We believe in the power of knowledge, investing in education through MIRAI Academy, and making knowledge accessible to our partners and academic audiences from universities and various educational organizations.

E.E: What estimations/plans do you have for the beginning of 2024?

V.T: What truly makes Mirai a strong company is its strategic partnerships with leaders in their respective industries.

MIRAI recently announced collaboration with Azenta Life Sciences and Refolution GmbH.

This collaboration represents a synergy of expertise across different fields. Azenta Life Sciences brings to the table its vast experience in life sciences and biobanking, while Refolution GmbH contributes its knowledge in refrigeration and cryogenic solutions.

This collaboration is set to redefine the future of automated biobanking through the introduction of the Azenta BioArc range, which will be powered by Mirai Intex’s advanced air cycle refrigeration machines. The air cycle technology is renowned for its environmental friendliness and ability to maintain consistent temperatures, which is critical for preserving sensitive biological samples. Biobanking, the practice of storing biological samples for research, is crucial for advancing medical research, developing treatments, and understanding diseases.

The core of this cooperation is sustainability. The use of Mirai Intex’s air cycle refrigeration machines in the Azenta BioArc range underlines a commitment to reducing the environmental impact of biobanking operations. This technology not only offers lower energy consumption but also eliminates the need for harmful refrigerants, aligning with global efforts to promote sustainability in scientific research and healthcare.

E.E: What can you tell us about market trends?

V.T: F-Gas Regulation is sparking discussions and action across industries. It aims to reduce the use of high-global-warming-potential F-gases, pushing for greener alternatives.

In February 2024, the European Union updated the F-Gas regulation, which regulates the use of fluorinated greenhouse gases. This update brings new measures aimed at further reducing F-gas emissions and strengthening sustainable alternatives. Among the main changes is a reduction in quotas for the sale of F-gases within the EU to promote a faster transition to greener technologies. Furthermore, the regulation enhances rules for monitoring and controlling the use of F-gases to prevent leaks and illegal trading.

Stakeholders are grappling with compliance challenges, especially in sectors like refrigeration and air conditioning. Overall, it’s driving a shift towards sustainability and a low-carbon economy.

We have also documented our efforts by obtaining the ATMO-Label. The ATMO-Label is a certification given by ATMOSphere (formerly known as Shecco) for products and technologies in the field of natural refrigerants. This label confirms that the given product or technology meets the highest standards for environmental friendliness and utilizes natural refrigerants with low or zero global warming potential. In 2022 MIRAI Intex placed in the market Natural Refrigerant-based equipment mitigating lifetime GHG emissions equal to 1,181,946 metric tons CO2e (GWP_20 Years). In 2023 MIRAI Intex was awarded the ATMO-Label as evidence of our commitment to sustainability and efforts to minimize negative environmental impact.

This approach aligns with our MIRAI strategy for the future. We are building a future where efficient refrigeration technologies play a key role in the sustainable development of industry and the planet. MIRAI is actively expanding its role in new markets, offering innovative ecological solutions. Through our advanced technologies, we empower our customers to achieve the most ambitious commitments to environmental impact reduction and sustainable development goals.