“It really is a phenomenal machine.” This is what Henk van de Graaf, employee of the Dutch cutting company Riam in Tiel, says about the panel edging machine from the Spanish manufacturer Cevisa (Castellanos y Echevarria – Vitoria, S.A.). This has been in operation at Riam since around 2 years and ensures straight and mirror-smooth welding edges. The plates are immediately ready for welding, reworking is no longer necessary.

Riam (fully Riam Dordrecht BV) is a provider of high quality cutting work. The company started out with custom cutting for shipyards in the Rijnmond region, but has expanded its scope over the years. Around 1,500 customers from a wide variety of industries are now placing their small and large orders, and Riam also supplies steel itself. Customers can be found in shipbuilding, offshore, petrochemicals, windmill construction, etc. “Our parts are everywhere,” says Van de Graaf. “We often don’t even know exactly what we’re cutting. We get a sketch with the task: do it. “

At the beginning of this year, Riam moved from Dordrecht to Tiel. Here the company has access to a much better and tidier production hall. It is a bit smaller than the hall in Dordrecht, but according to the director / owner Siem van den Berg this also has its advantages: “You don’t have to search so much. And if you have a lot of space, customers think they can take all of their material with them. “

Riam cuts up to 30 cm thick (we work with a partner for even thicker material). Two plasma cutters and an oxy-fuel cutting machine are set up for this. In addition, a plasma cutter is in production and a machine is kept in reserve. They employ 23 people who work in two shifts.

Weld edge preparation

An important part of the service is the preparation of the welded edges. Welding edges can be made directly on the cutting machine, but reworking is then required before the plates can be welded. Milling produces much better weld edges. At Riam they have always done this manually, with a hand machine that moves along a plate over a rail. This is a labor-intensive effort that generates a lot of dust and is accompanied by a lot of noise. More importantly, the processing speed is slow and the quality is not consistent.

The hand-held machine is still in use – for processing round edges, for example – but there is also the Cevisa model CHP-60G plate-edge bevelling machine. This was made available by the company Th. Wortelboer B.V. from Heumen, which is representing the Spanish manufacturer for 35 years. Van den Berg and Van de Graaf saw this machine at the booth from Th.Wortelboer B.V. at the TechniShow. They rented the machine first to test it out extensively and then bought it.

The Cevisa beveling machine ensures straight and mirror-smooth welding edges. The plates are immediately ready for welding, no further processing is required.

Milling with inserts

The machine mills with carbide inserts (with two cutting edges). Seven inserts are inserted into a milling head with a diameter of 80 mm. A bevel is milled onto a plate or part of a plate. The milling machine has a variable speed per minute and a separate drive for feeding and / or transporting the machine along the plate. The CHP-60G mills plate thicknesses up to 70 mm, but Cevisa also supplies models for up to 100 mm. The maximum bevel length is 60 mm, which requires several runs. The machine can remove 28 mm in one pass, regardless of the type of material. The angular position is adjustable from 15 to 70 degrees and the pneumatically adjustable working height from 750 to 950 mm. The machine also has a spring-loaded chassis. This is an advantage if the plate sags. The machine adapts easily.

The bevel cutter is a mobile device on wheels and has a spring-loaded base.

Processing speed

The bevelling machine is a mobile device on wheels (it weighs 800 kilos and can be pushed by one man). Riam placed them on three tables with a total length of 12 meters. Rollers are fitted in these tables so that one plate can be easily rotated to process the other side. “It works ideally. You adjust the machine, place it against the plate and it pulls through it. In the meantime, you can get yourself a cup of coffee”, smiles Van de Graaf.

He’s lyrical about the machine. “We’ve improved tremendously in terms of speed. With the hand machine on a rail, you can reach 180 mm per minute. The Cevisa machine reaches 350-400 mm per minute and with steel we can even reach half a meter per minute. It’s also very accurate. It mills much better than a manual machine. An ironworker no longer needs staples. “

Exceed limits

What Van de Graaf also likes is that he can get more out of the machine than the manufacturer and supplier promise. “You have to take it seriously and work according to the regulations.” These rules are not complicated. Setting up the edge cutter is simple and easy to use. A clear diagram shows for which material types / thicknesses which feeds and speeds of the milling head are suitable. Setting the degrees and determining the zero point is also child’s play. “It has wonderful thermal protection,” says Van de Graaf. “This way you can exceed the limits and get the most out of the machine without risk of damage.”

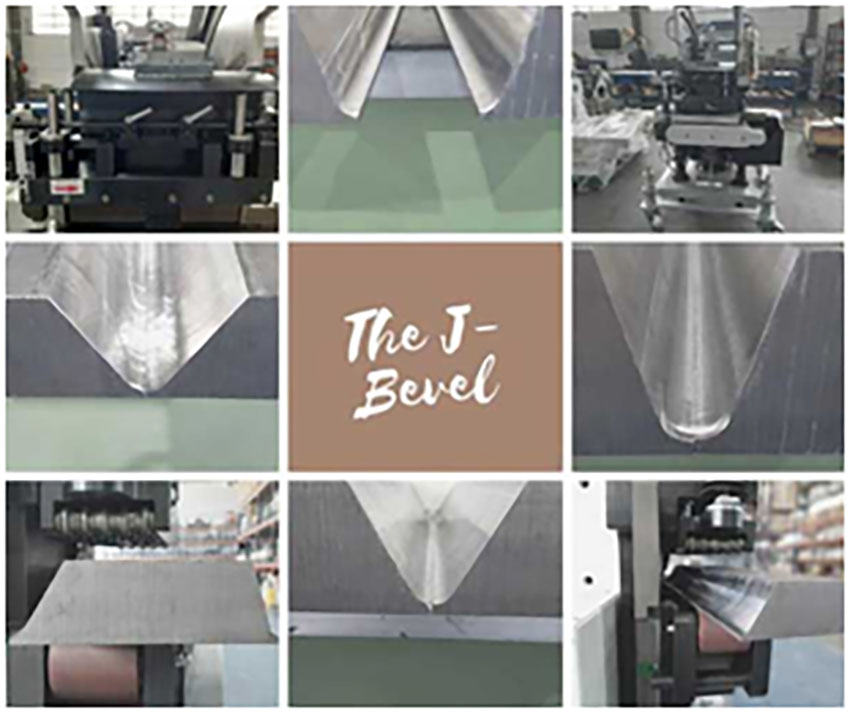

Cevisa has an extensive range of beveling machines. For example, there is also a model for milling J-chamfers.

Machines like these are the future, according to Van den Berg and Van de Graaf. “We’re making real progress with this. If it is possible to get the job done on this machine, we will do so. “Your next wish is a bevelling machine that can also provide the bottom edge of a plate with a welding seam. “Such a model is also in the range,” says Jeroen Wortelboer from supplier Th. Wortelboer B.V. “Cevisa has an extensive range of chamfering machines. For example, there is also a device for milling J-chamfers. And if you are processing material that is only 10 mm thick, the machine runs twice as fast. If you wish, you can also process 80 to 100 mm per minute. Special models for stainless steel are also available, in which the steel wheels of the upper guide are coated with plastic and the rear guide is made of stainless steel. In this way you can serve each customer very specifically. “