MX3D specialises in robotic wire arc additive manufacturing (WAAM). Converting industrial robots into 3D metal printing systems allows the user more flexibility. Their dedicated robotic WAAM software enables companies, engineers and designers to print end-to-end large-scale 3D metal objects in-house.

Interview with René Backx, COO & Pierre Freneau, Business Developer at MX3D.

Easy Engineering: What are the main areas of activity of the company?

René Backx & Pierre Freneau: The main activities are enabling clients with their own M1 robotic printing setup to perform 3D metal printing to their specific needs and requirements. In addition, we offer print-on-demand services to individuals to utilise the technology with the aid of our experienced design and manufacturing teams.

E.E: What’s the news about new products?

R.B & P.F: We currently have new hardware product additions, being incorporated into our already capable additive manufacturing systems, these advancements will allow users to accelerate their product development cycle and have more control over speed, quality and cost.

E.E: What are the ranges of products?

R.B & P.F: Our dedicated software package MetalXL incorporates easy-to-use applications and feedback responses. We are further developing hardware additions for the M1 allowing customers to optimise process capabilities.

E.E: At what stage is the market where you are currently active?

R.B & P.F: There is a positive outlook for the 3D metal printing market, with continued growth and innovation expected in the coming years. Growing industrial adoption has led to certification and standardisation.

E.E: What can you tell us about market trends?

R.B & P.F: WAAM is still evolving, and ongoing research and development efforts focus on improving process control, developing new materials, enhancing software solutions, and optimising the overall printing process.

E.E: What are the most innovative products marketed?

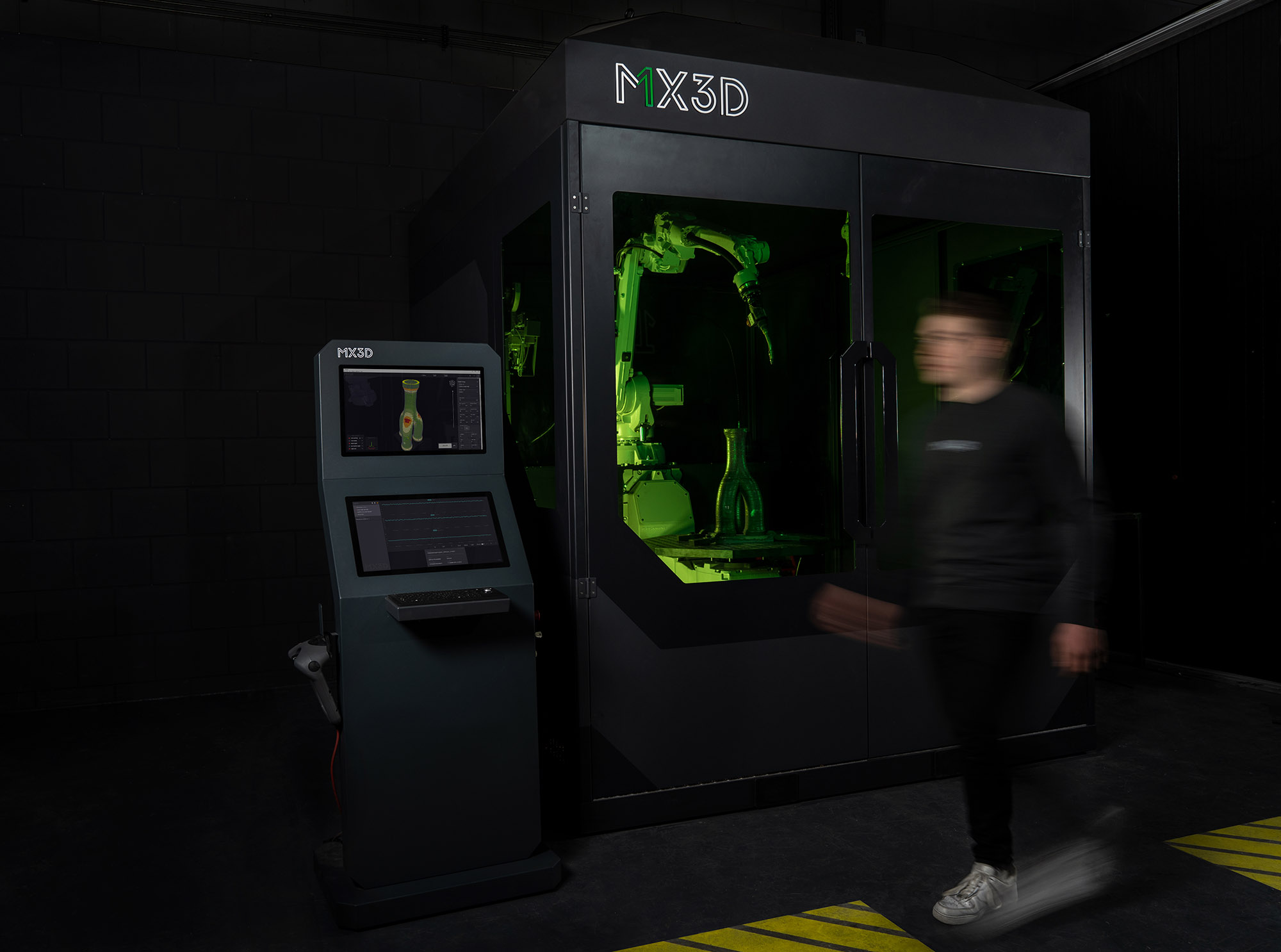

R.B & P.F: The M1 is our flagship system for large industrial applications, this printing cell is ideal for large-scale prints utilised by designers and engineers within various industries. M1 includes an 8-axis industrial robotics system enabling complex prints and a multi-transfer mode GMAW power source for flexible print procedures.

MX3D’s WAAM-dedicated control system features intelligent automation, real-time print monitoring and high-resolution data logging.

E.E: What estimations do you have for 2023?

R.B & P.F: Continuous innovation is expected to address the challenges associated with WAAM and further expand its capabilities and applications. There is also a significant rise in demand for the automotive, aerospace and nuclear industries to integrate the technology.