MySolutions is manufacturer and supplier of automated All-In-One manufacturing solutions. Their know-how and great passion cover the entire range of industrial sectors. In addition to the in-house development of the company’s modular hardware/software products, MySolutions is specialized in the individual connection and networking of existing systems.

Therefore, in addition to MySolutions’ complete solutions, they can also support you with individual modules from the areas of ERP, PPS, MES, CMMS and much more.

Interview with Paul Gossens, Chief Executive Officer at MySolutions AG.

Easy Engineering: What’s the news about new products?

Paul Gossens: The MyXPert® ToolManager ensures that tools are sufficiently available through the modular storage system «THE BOX», correctly mounted and set within the specified tolerances and accurately measured. Based on the central data structure, the determined and checked measured values are directly available in the memory of the CNC control, if required. Just as the NC programmer intended when creating the program.

The innovative modular THE BOX storage system offers stable storage of small to medium-sized products of any kind. The different drawer heights of 40 mm or 100 mm can be individually divided. The storage systems are also optimally suited for companies with small footprints and room heights.

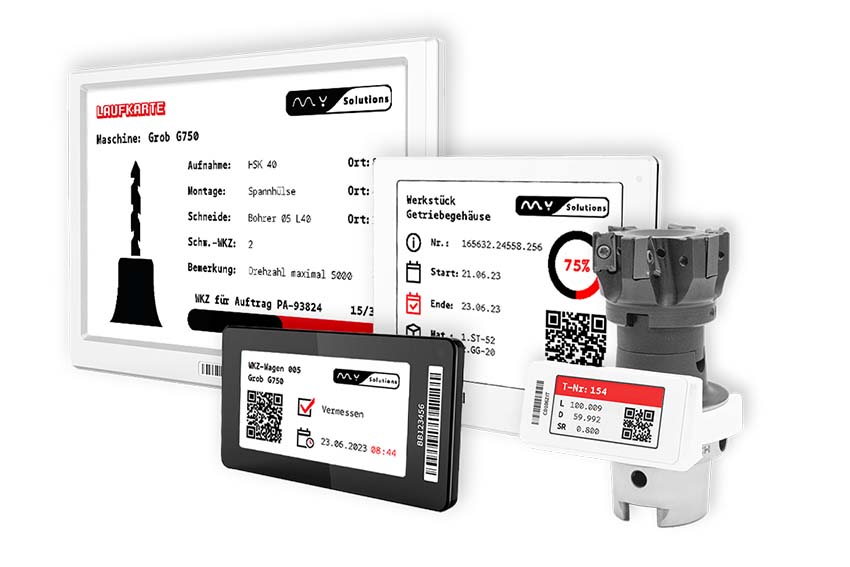

The MyXPert ePaper Displays are solutions with the advantages of paper. Our low-power display technology is ideal for use in the SmartFactory. You can display text, progress, and graphics without losing the benefits of paper. Discover how MyXPert ePaper can be used in manufacturing and logistics to display markings, labels and more on digital paper.

E.E: What are the ranges of products?

P.G: We have a wide range of products: From Software like the MyXPert ProductionManager, MyXPert ToolManager, MyXPert Monitoring, MyXPert OfficeManager and MyXPert Data capture to our newest innovations like the vertical automated storage system THE BOX or the digital paper solution MyXPert ePaper.

E.E: At what stage is the market where you are currently active?

P.G: Due to increasing international competition, optimization processes in manufacturing are imperative. Just-in-time production, which has been strived for some time and has also been implemented successfully in some cases, increasingly requires a direct communication channel. An unnecessary production standstill due to a missing or defective tool can very quickly increase costs massively. With our hardware and software solutions, we can react quickly and keep downtime as low as possible. Motto: a machine that produces brings money – a machine that stands still costs money!

E.E: What can you tell us about market trends?

P.G: Modern production facilities are increasingly using modern handling equipment such as robots, automatic transport systems, etc. This in combination with a customizable software solution will be another step towards automated production. This combination will enable a further step towards unmanned production and additional night shifts.

E.E: What are the most innovative products marketed?

P.G: The knowledge accumulated for many years has always been realized by means of practical projects. Our advantage is the modular software framework that can be integrated into existing IT systems. The most innovative product at the moment is a storage cabinet system (THE BOX) for equipment with a direct integration to already existing logistic systems. This new storage system allows ergonomic use as well as a connection to handling systems.

E.E: What estimations do you have for the rest of 2023?

P.G: Based on experience from recent years, the current demand for optimization concepts is very high. In our market area, investments are increasingly being made in falling or rising economic situations. Due to this, there will still be some positive projects until the end of the year or the next 6 months.