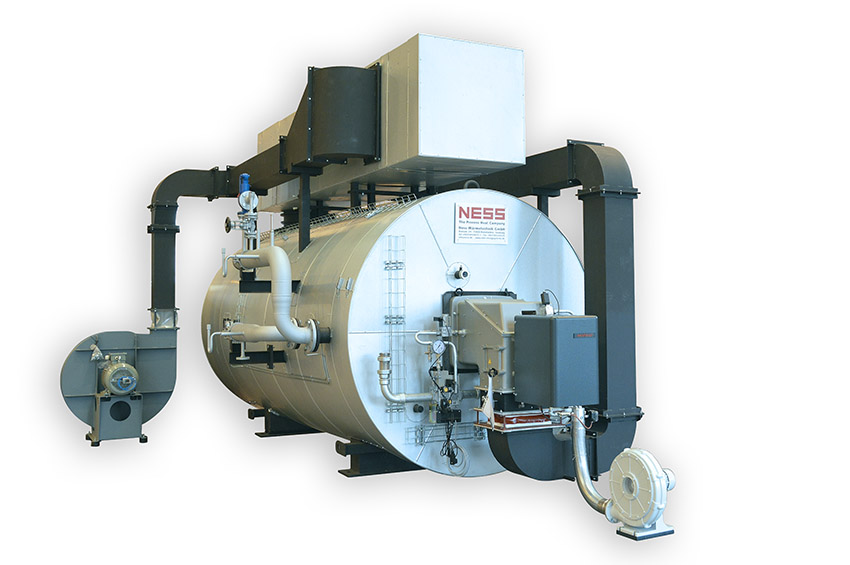

For more than 55 years, Ness has been developing solutions for process heating systems in Remshalden near Stuttgart. The company employs more than 90 people in development, planning, sales, manufacturing and service.

In engineering, around 30 highly qualified and motivated engineers from all areas of technology work on implementation solutions for customers on all continents.

The experience of Ness’ planning and service engineers gained in their projects is consistently implemented into new products and services. National and international development projects are regularly carried out and successfully completed.

An efficient service team ensures a smooth worldwide logistics of products and spare parts, professional assembly and commissioning of the equipment. In addition, the company offers maintenance, repair and modernization of existing plants – focusing on performance, availability, safety and energy efficiency.

Easy Engineering: What are the main areas of activity of the company?

NESS: We offer high quality systems which deliver heat to a variety of processes in different industries. They are used, for example, in the wood industry, paper industry, plastics industry, petroleum industry and chemical industry.

E.E: What’s the news for 2021 about new products?

NESS: A fairly new product is the NESS Smart HeaterPump.

Due to the present state-of-the-art, heat transfer oil heaters must be operated with the full flow rate, also when the full heat output is not required, and the heater works with partial load. This is now a problem of the past!

Electrical power consumption of a pump depends on the third exponent of the flow rate and typically, much more oil is pumped through the heater than what is required for safe operation of the system. Adding the optional NESS Smart HeaterPump, the load on the heater is monitored and the fl ow rate will be automatically set preventing the unnecessary waste of electricity.

Considering an average utilization of 80%, the operating costs for electricity can be reduced by approximately half. Also, the Smart HeaterPump is designed for maximum functional safety thanks to a redundant design. The Smart HeaterPump achieves the Safety Integrity Level 2 (SIL 2) and has been certified as a minimum flow limiter according to DIN 4754-2.

The flow rate through a heat transfer oil heater is selected in a way that at full load, a desired temperature spread between flow and return flow is achieved. The specified film temperature of the heat transfer medium can never be exceeded in any operation. For this reason, the required minimum volume flow at full heater load is usually determined and then monitored. The NESS Smart Heater Pump continuously determines the required volume flow depending on performance required. However, if the heater is operated at partial load or the current flow temperature of the oil is lower, the film temperature in the heater is also lower. The oil flow through the heater can be lowered without exceeding the maximum specified film temperature.

E.E: What are the ranges of products?

NESS:

- Thermal oil systems;

- Steam systems / Hot water systems;

- Heat exchanger systems;

- Integrated process heat supply;

- Biomass heating systems;

- Heating and Cooling Systems;

- Thermal afterburning;

- Engineering;

- Operator training and Auditing;

- Service.

E.E: At what stage is the market where you are currently active?

NESS: The market – especially in the wood industry – is growing strongly worldwide at the moment. The annual turnover of NESS in 2020 was about 20 million euros.

E.E: What can you tell us about market trends?

NESS: We see that our customers are looking for high efficiency heaters with low emissions and reliable, automated operation. There is too a constant demand for our biomass heaters.

E.E: What are the most innovative products marketed?

NESS: We have a product line called NESSessities dedicated exclusively to the safety, availability, durability and efficiency of thermal oil systems. Many of our customers want to operate their plants not only safely, but also as efficiently and sustainably as possible. Since these products are also very easy to integrate into existing plants at a good price, many use these product solutions to achieve this. As this product line is constantly being expanded and improved together with our customers, we will certainly continue to expand this business area in the future.

E.E: What estimations do you have for 2021?

NESS: 2021 is developing very well so far. We expect a further increase in sales this year compared to previous years and are very optimistic to reach our high targets.